Filtering and slag-discharging system

A filter barrel and secondary filtration technology, applied in the direction of filtration separation, filtration circuit, fixed filter element filter, etc., can solve the problems of waste oil accumulation, environmental pollution, cloth bag clogging, etc., and achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

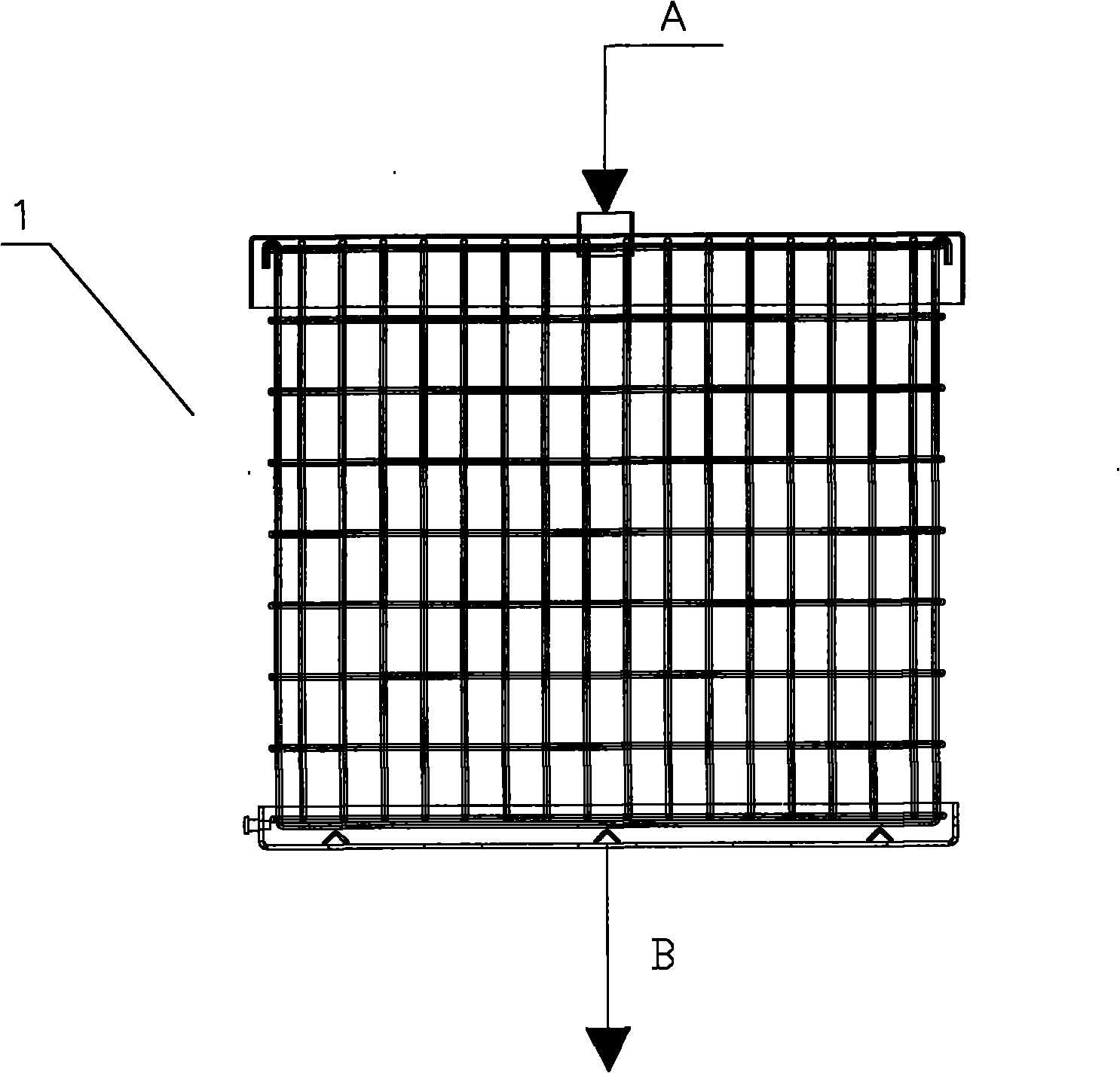

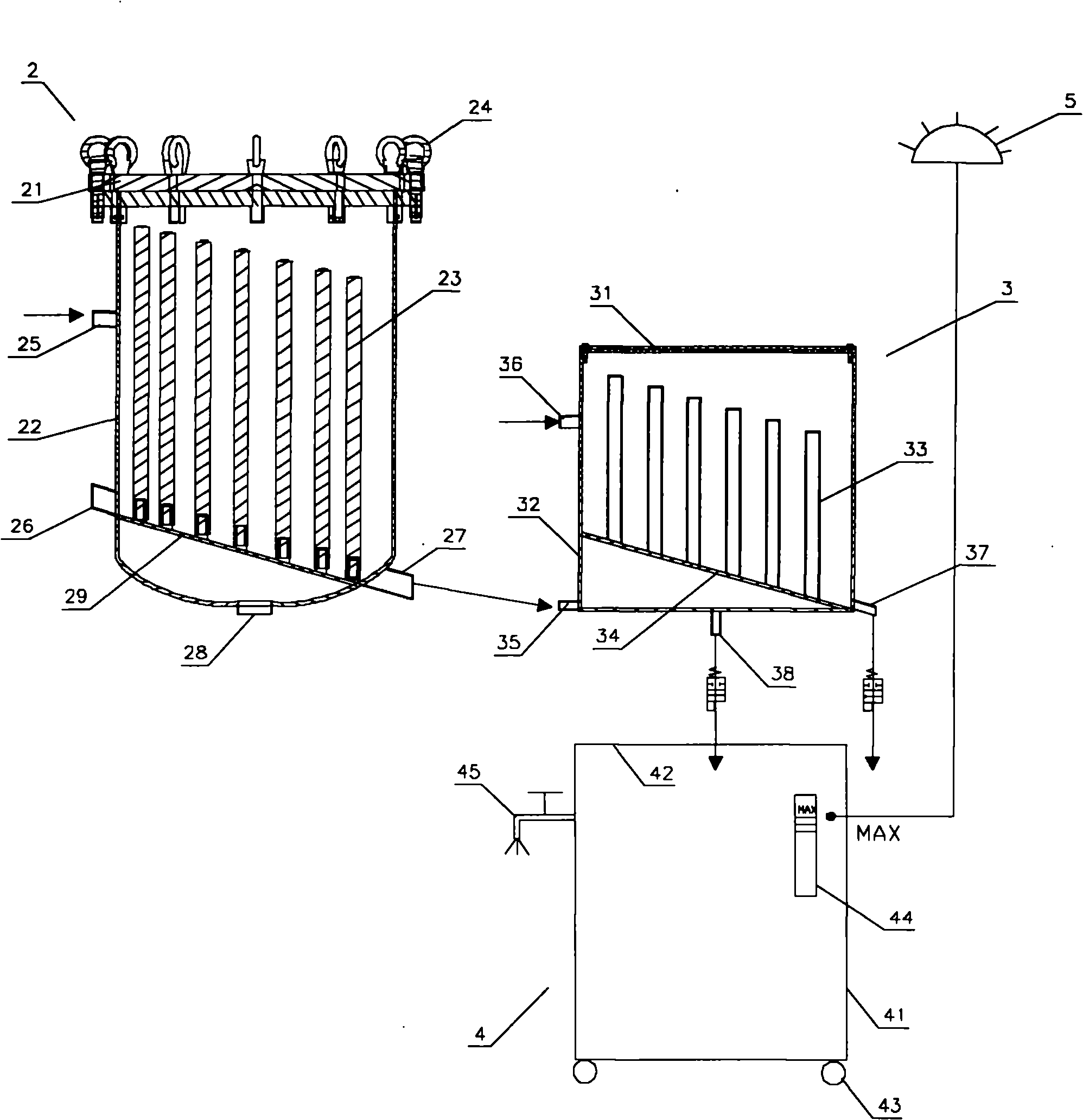

[0024] refer to Figure 3-4 , the filter and slag discharge system includes a filter bucket 2, a secondary filter device 3 and a sludge collection vehicle 4;

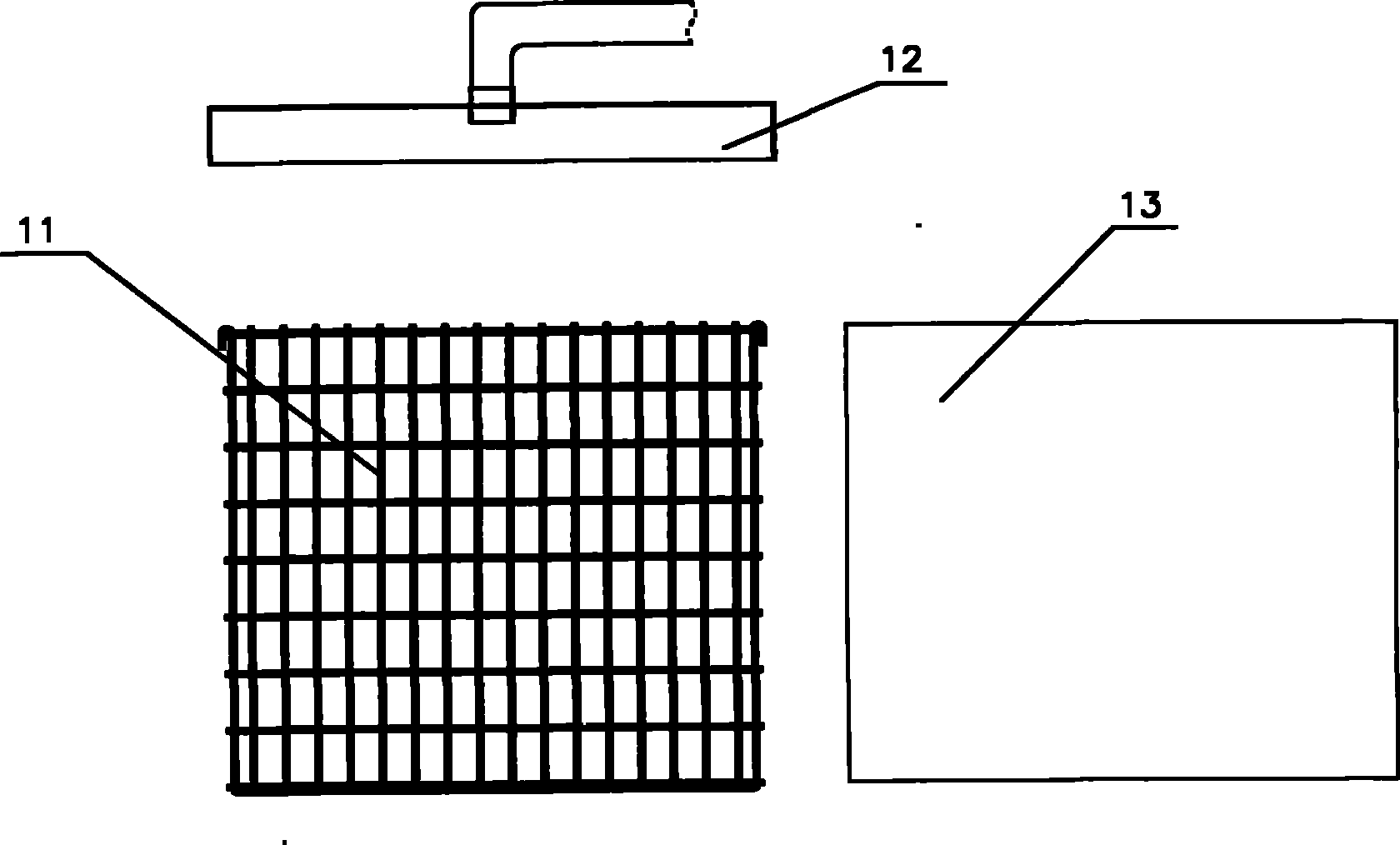

[0025] Wherein, filter bucket 2 comprises bucket body 22, bung 21 and filter element 23, and described bucket body cavity is divided into upper cavity and lower cavity by a flange plate 29 that is inclined to be arranged in the barrel body cavity, and lower cavity and The clean oil outlet 28 arranged on the lower part of the barrel communicates, and the upper cavity communicates with the dirty oil inlet 26 and the dirty oil outlet 27 respectively arranged on the barrel corresponding to the uppermost and lowermost positions of the flange, and the lower end of the filter element communicates with the The flanges are connected by a screw fastening structure, and an opening is set on the lower end surface of the filter element, and the opening communicates with the lower chamber, and at the same time, the barrel body is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com