Air-floating working platform for ultrasonic processing

A workbench and ultrasonic technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of high cost of hydraulic system, complex numerical control system, unfavorable wide application, etc., and achieve low cost, simple maintenance, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

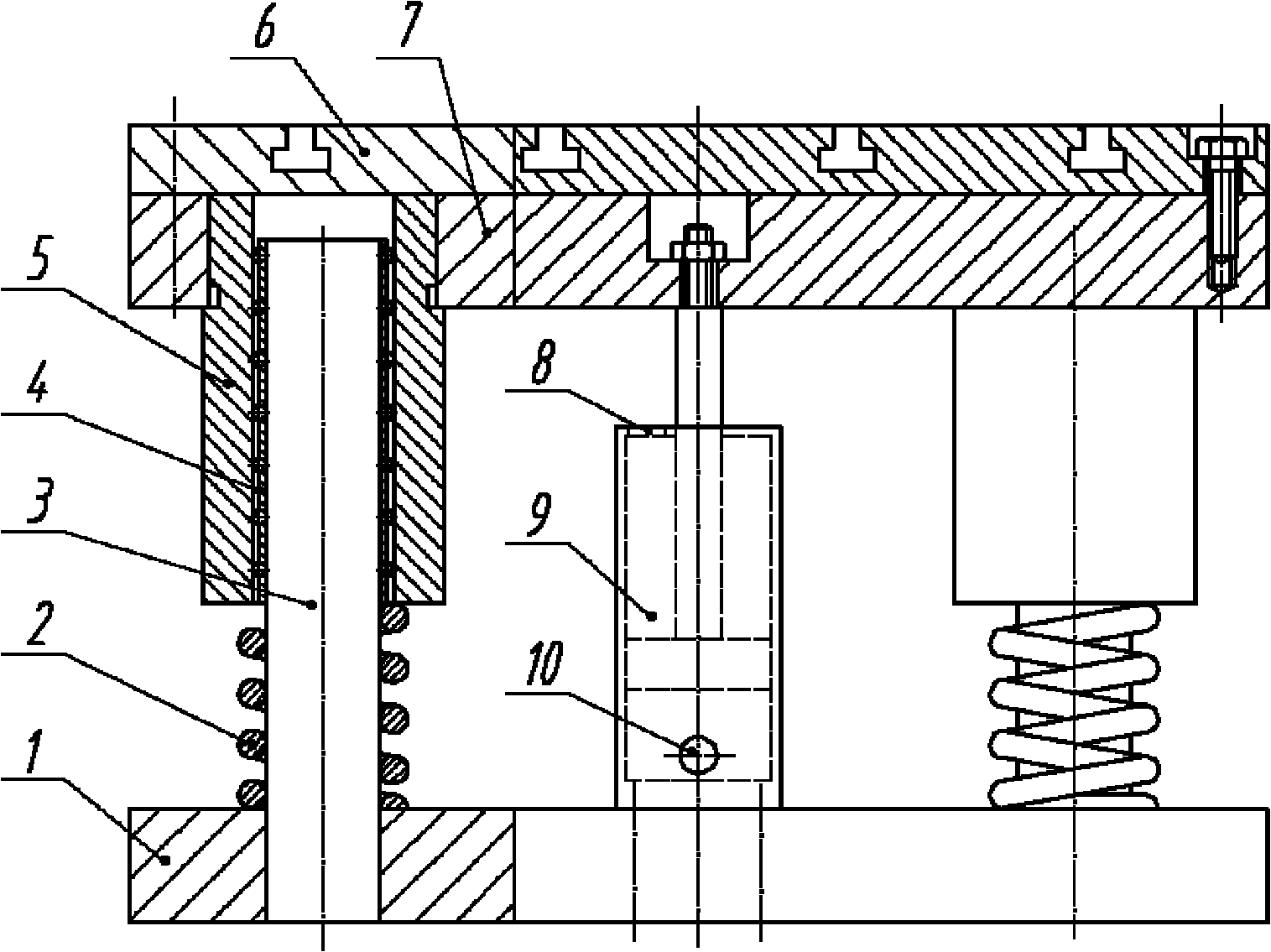

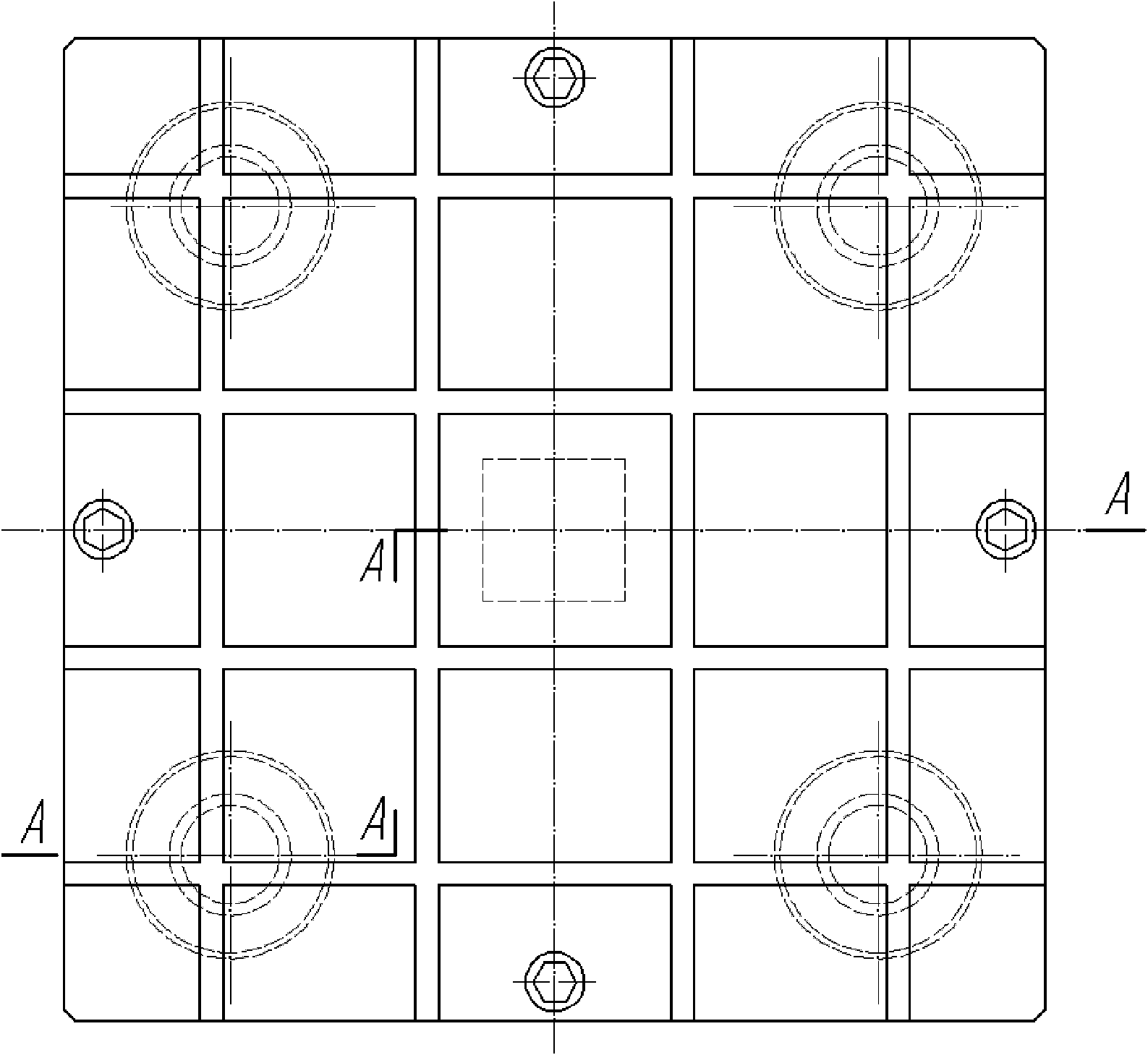

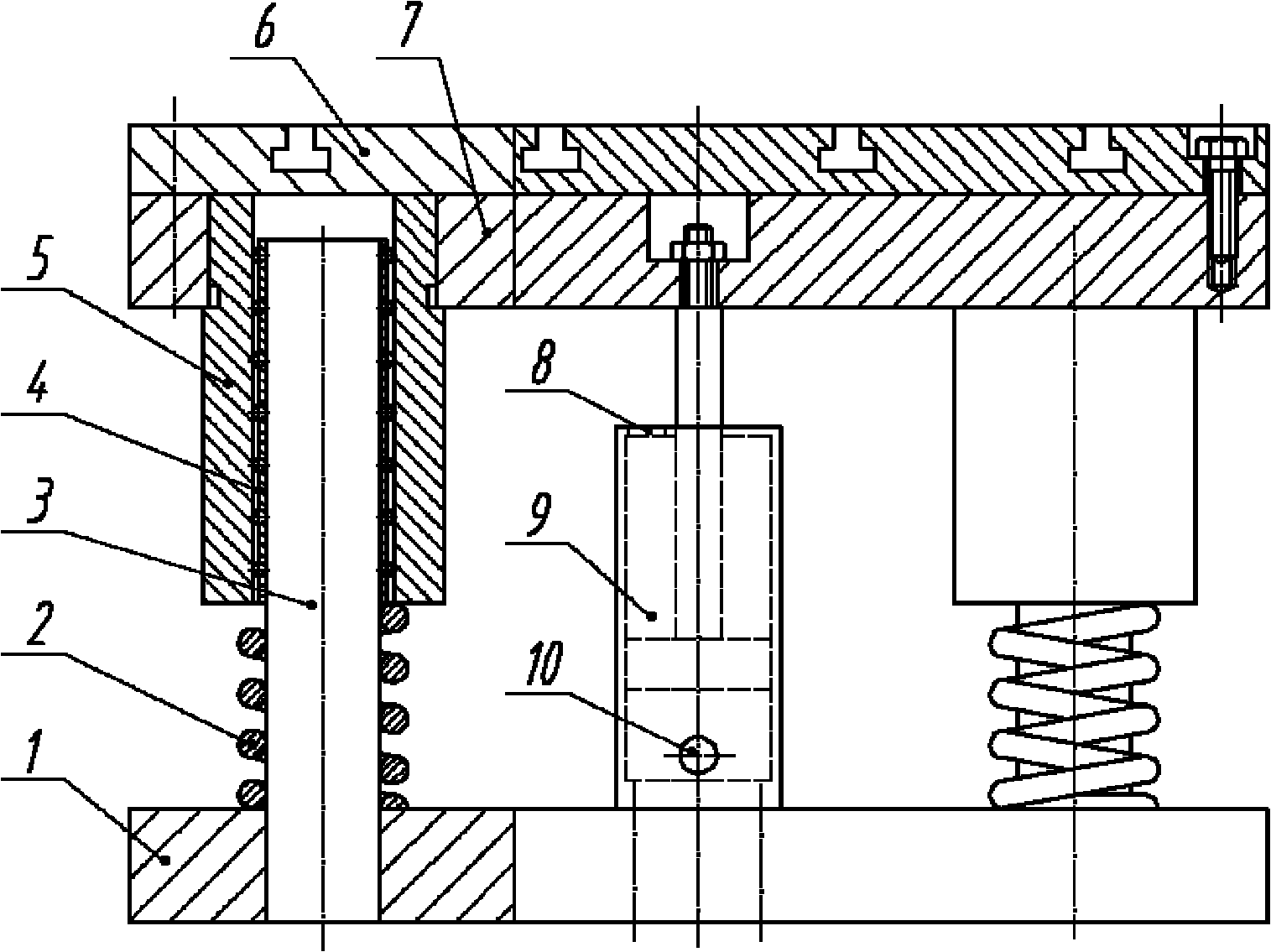

[0008] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

[0009] As shown in the accompanying drawings, an air-floating workbench for ultrasonic processing includes a base 1, at least four guide rails 3 are perpendicular to the base 1 and evenly and symmetrically distributed on the base 1, and one end of each guide rail 3 It is fixedly connected with the base 1 and its other end is placed in a guide sleeve 5 through the ball bushing 4, and a spring 2 is sleeved on the guide rail 3 between the bottom end of each guide sleeve 5 and the base 1, and each guide sleeve 5 The upper end of the upper end is fixedly connected with the support plate 7, and the work surface 6 is fixedly connected with the support plate 7. A cylinder 9 is arranged at the center of the base 1. The cylinder 9 and the piston rod of the cylinder 9 are arranged perpendicular to the base 1. The cylinder 9 has no piston. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com