Cutting tool for high-speed cutting

A cutting tool, high-speed cutting technology, applied in the field of metal cutting, can solve the problem of short effective contact length between fasteners and threaded holes, small effective contact area between fasteners and tool holders, large axial force and rotary centrifugal force, etc. problem, to achieve the effect of low production cost, simple and compact structure, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

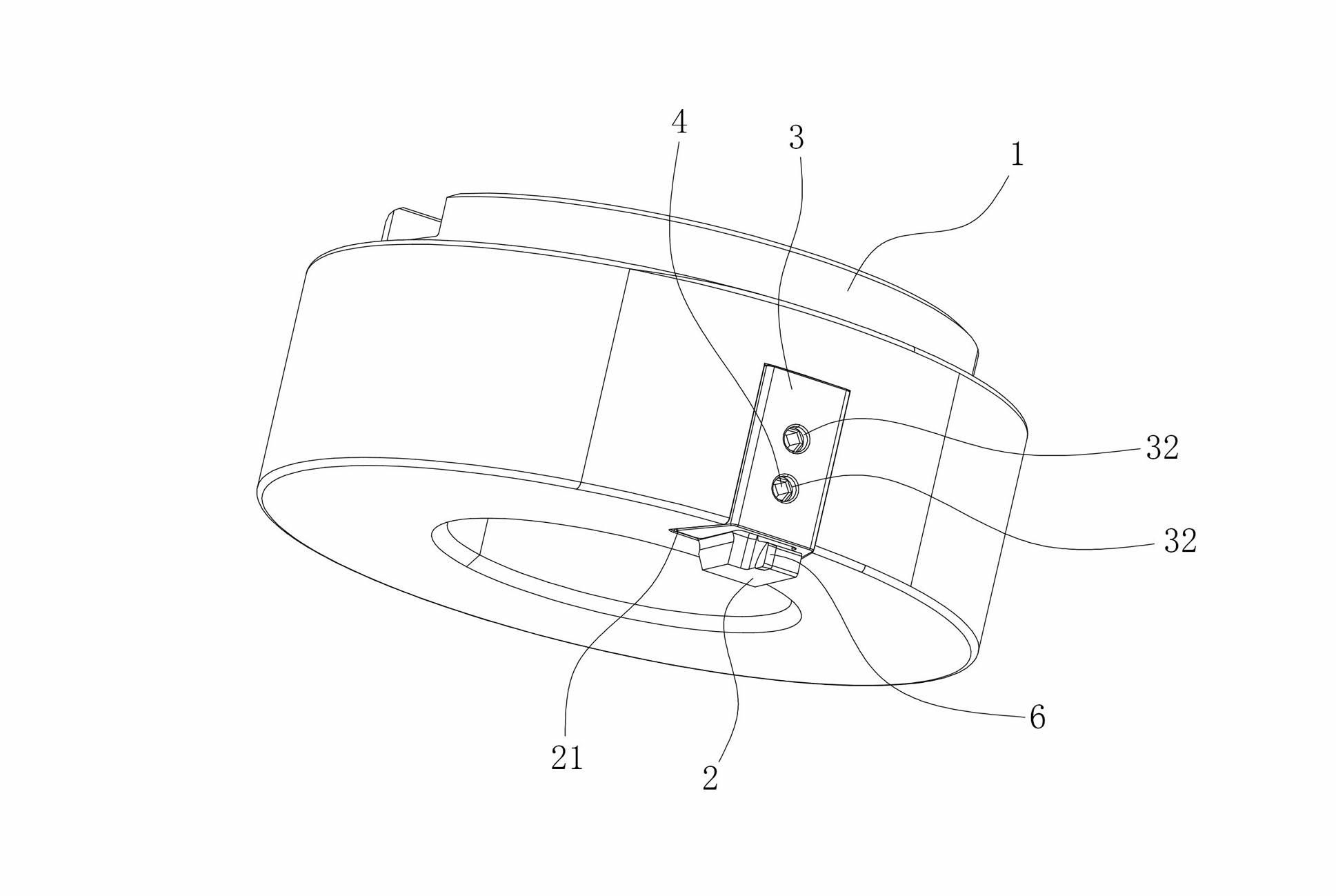

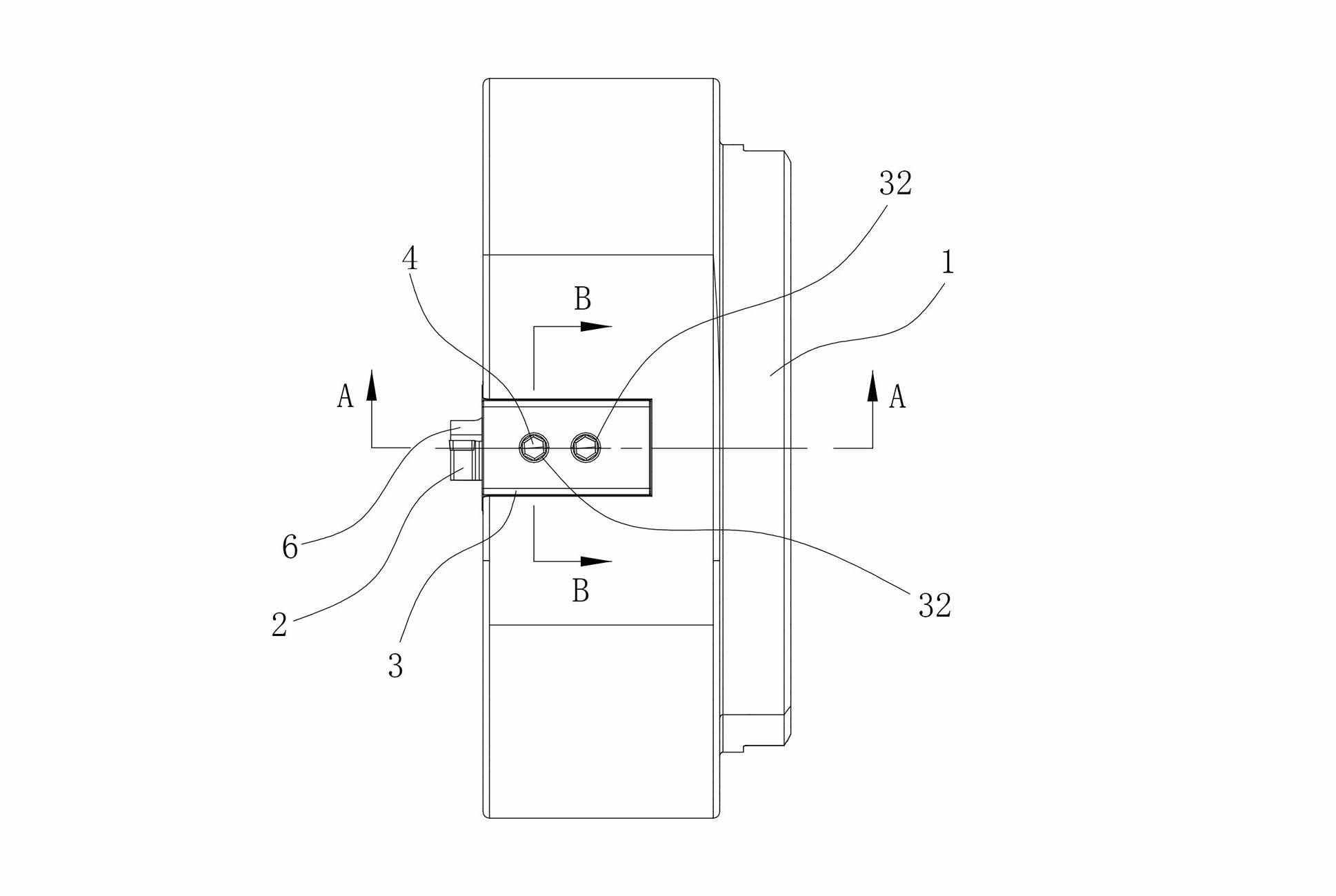

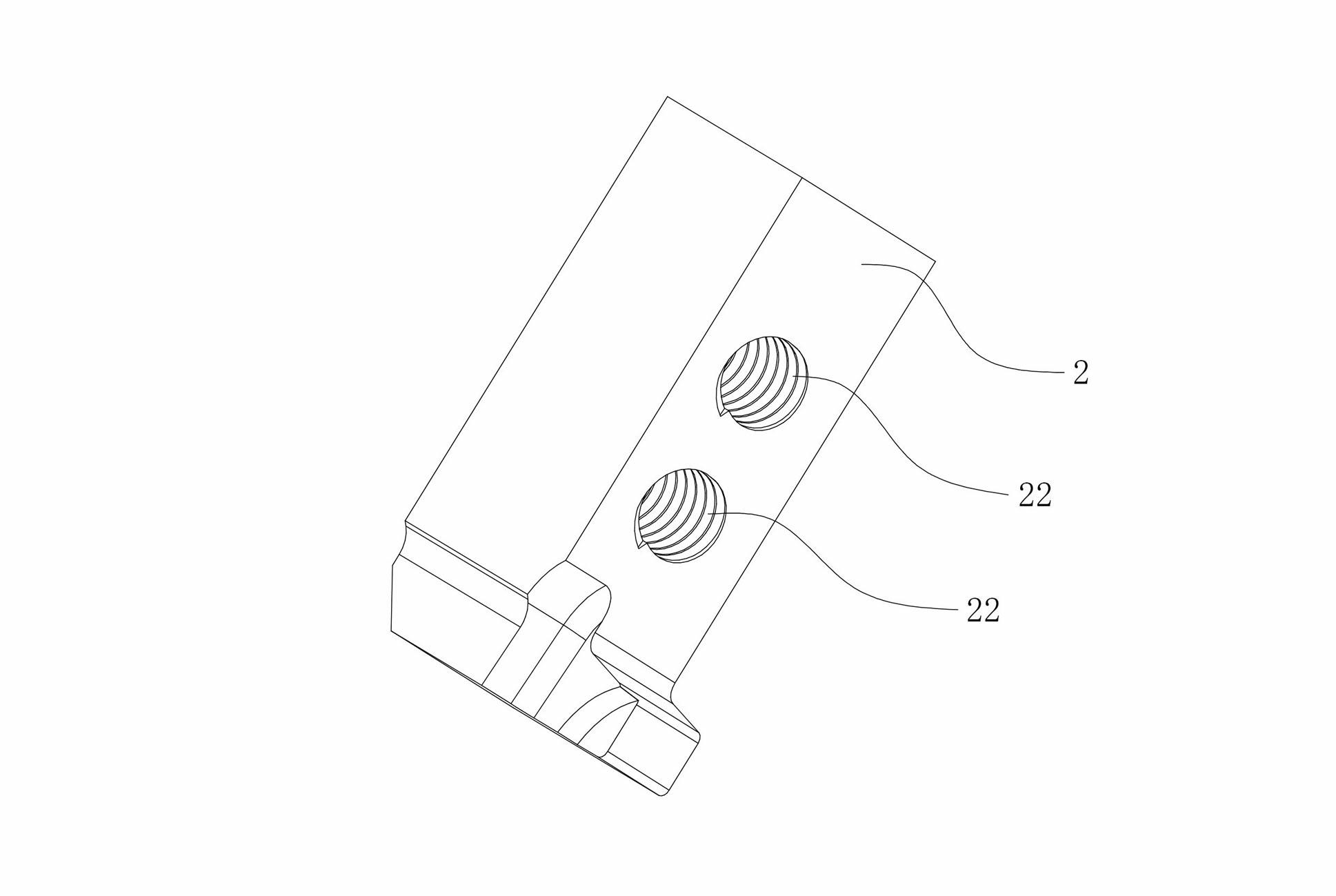

[0022] Figure 1 to Figure 7 A cutting tool embodiment for high-speed cutting of the invention is shown, the cutting tool includes a cutter body 1, and the cutter body 1 is provided with at least one set of sipe grooves 21 with a wedge-shaped cross section, and the number of sipe grooves 21 can be determined according to the specific Depending on the cutting situation, the present embodiment is only provided with one group of sipes 21, which are equipped with toolholders 2, wedges 3 and fasteners 4, and the wedges 3 are provided with a knife with an opening facing the bottom of the sipes 21. The clip accommodation groove 31, the tool holder 2 is placed in the tool holder accommodation groove 31, the cutting blade 6 is installed on the tool holder 2, and the threaded hole 22 corresponding to the fastener 4 is provided, and the fastener 4 is threaded on the In the threaded hole 22 of the tool holder 2, the head 41 of the fastener 4 is pushed against the bottom surface of the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com