Equipment and method for producing coating surface bleached kraft liner board

A production equipment and a technology for kraft paperboard, applied in the field of papermaking, can solve the problems of poor product quality, low production efficiency, poor coating effect, etc., and achieve the effects of improving surface smoothness, simplifying production steps, and low coating amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

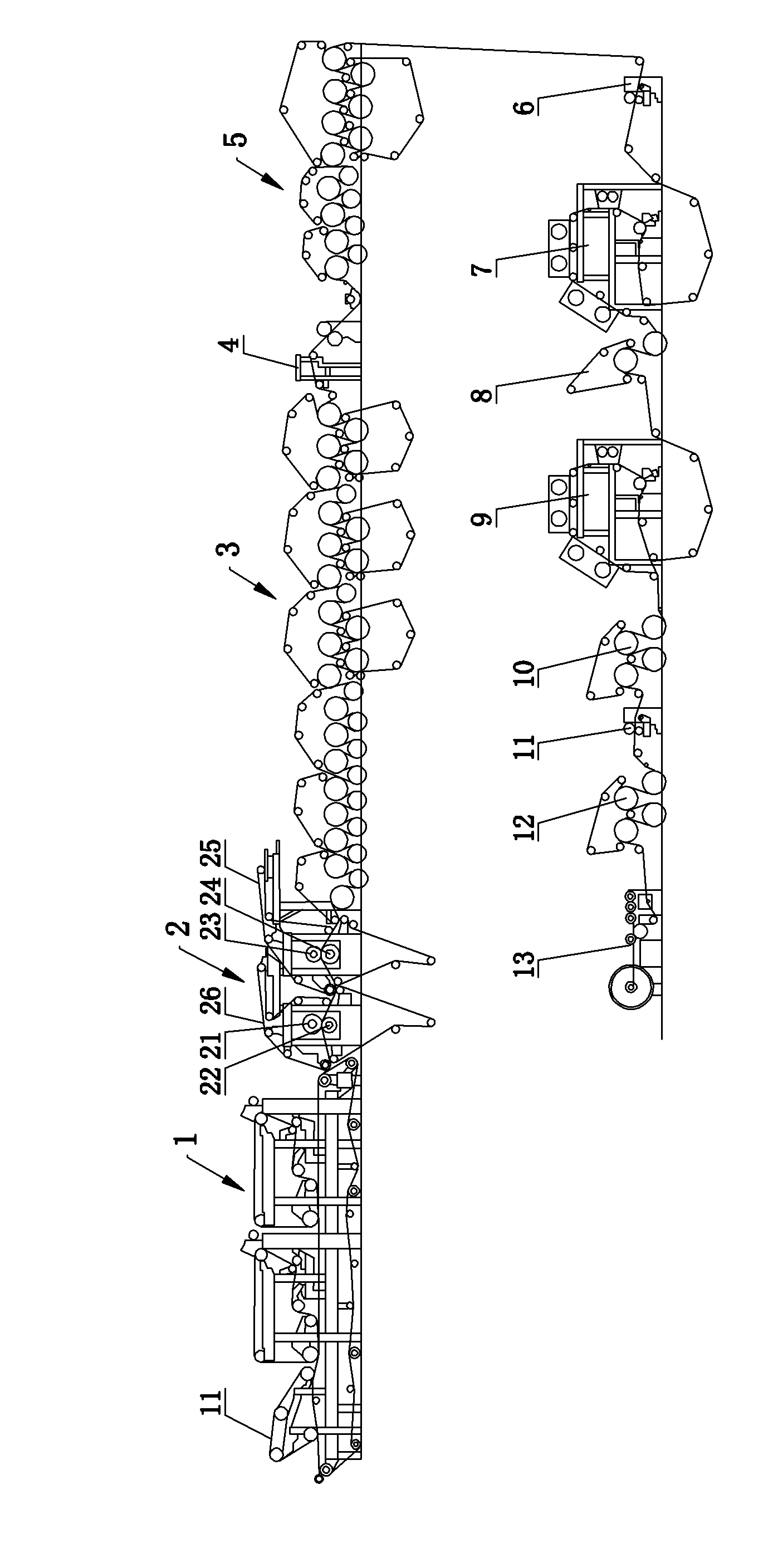

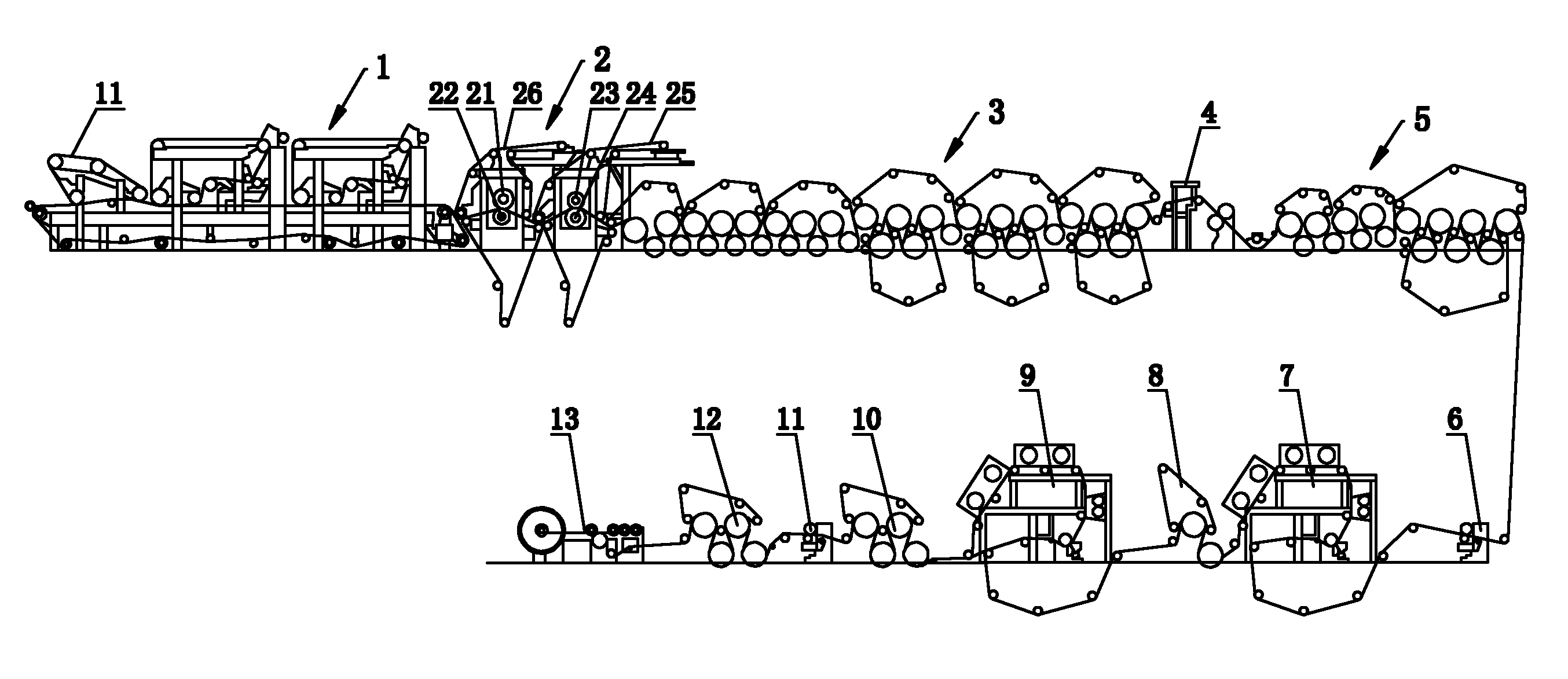

Image

Examples

Embodiment 1

[0029] The bottom layer slurry, lining layer slurry and surface layer slurry were prepared respectively. The bottom layer slurry used OCC waste paper as raw material, the lining layer slurry used mixed office waste paper as raw material, and the surface layer slurry used bleached wood pulp as raw material. The bottom layer slurry, liner layer slurry and surface layer slurry are compounded on a triple-wire forming device at a content ratio of 40wt%, 30wt% and 30wt%, respectively, to obtain raw cardboard.

[0030] The base paperboard is squeezed to remove moisture by a pressing device, the pressing device includes two straight-through shoe presses, the pressing pressure of the first shoe is 800kN / m, the pressing pressure of the second shoe is 1000kN / m, and the pressing pressure of the two shoes is 1000kN / m. The first shoe press upper roll and the second shoe lower roll of the straight-through shoe press device are shoe rolls, the second shoe press upper roll uses a shoe press bel...

Embodiment 2

[0034] Prepare bottom layer slurry, lining layer slurry and surface layer slurry respectively, bottom layer slurry adopts occ waste paper as raw material, lining layer slurry adopts waste newspaper as raw material, and surface layer slurry adopts bleached wood pulp as raw material, the Base layer slurry, liner slurry and surface layer slurry are compounded on a triple-wire forming device at a content ratio of 50wt%, 25wt% and 25wt%, respectively, to obtain base paperboard.

[0035] The base paperboard is squeezed to remove moisture by a pressing device, which includes two straight-through shoe presses, the pressure of the first shoe is 900kN / m, the pressure of the second shoe is 1000kN / m, and the pressure of the two shoes is 1000kN / m. The first shoe press upper roll and the second shoe lower roll of the straight-through shoe press device are shoe rolls, the second shoe press upper roll uses a shoe press belt, the first shoe press upper roll, the first shoe lower roll and the se...

Embodiment 3

[0039] Prepare bottom layer slurry, lining layer slurry and surface layer slurry respectively, described bottom layer slurry adopts occ waste paper as raw material, described lining layer slurry adopts mixed office waste paper and waste book paper as raw material, and described surface layer The slurry uses mixed office waste paper and white paper strips as raw materials, and the bottom layer slurry, liner layer slurry and surface layer slurry are respectively prepared in a three-fold wire forming device according to the content ratio of 72wt%, 16wt% and 12wt%. The original cardboard is produced by composite papermaking.

[0040] The base paperboard is squeezed to remove water through a pressing device, and the pressing device includes two straight-through shoe presses, the pressing pressure of the first shoe is 1000kN / m, and the pressing pressure of the second shoe is 1100kN / m. The first shoe press upper roll and the second shoe lower roll of the straight-through shoe press d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com