Measuring device adopting solid-state vibration angular rate sensor group to realize north-seeking underground

An angular rate sensor, solid-state vibration technology, used in surveying, earthmoving, wellbore/well components, etc., can solve problems such as low accuracy and reliability, limited methods and means, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Due to the complexity of the measurement environment in petroleum and geological drilling, it is a challenging task to use solid-state vibration angular rate sensors to measure azimuth and drilling tools to perform measurement while drilling. For example, a measurement tool will experience an acceleration shock along the direction of the sensitive axis of the angular velocity measurement. Because solid-state vibration angular rate sensor errors are a function of sensitive acceleration, small accelerations can also cause large angular rate errors. Vibration can cause fluctuations in the output of solid-state vibration angular rate sensors, leading to increased random errors. In addition, because the solid-state vibration angular rate sensor uses a feedback loop, high frequency vibration may introduce unnecessary errors.

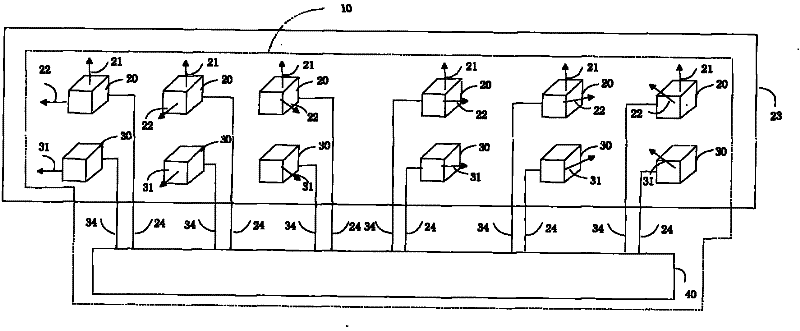

[0024] Such as figure 1 , which is a schematic diagram of the measuring device 10 .

[0025] Surveying device 10 may be used as part of inertial mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com