Surface high-temperature measurement device for nonmetallic heat resistant material plane test piece of hypersonic speed aircraft

A heat-resistant material and hypersonic technology, applied in measuring devices, thermometers using directly heat-sensitive electric/magnetic elements, measuring heat, etc., can solve problems such as thermal ablation, thermal damage, and expensive heat-resistant test pieces , to achieve the effect of convenient use, accurate measurement results and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

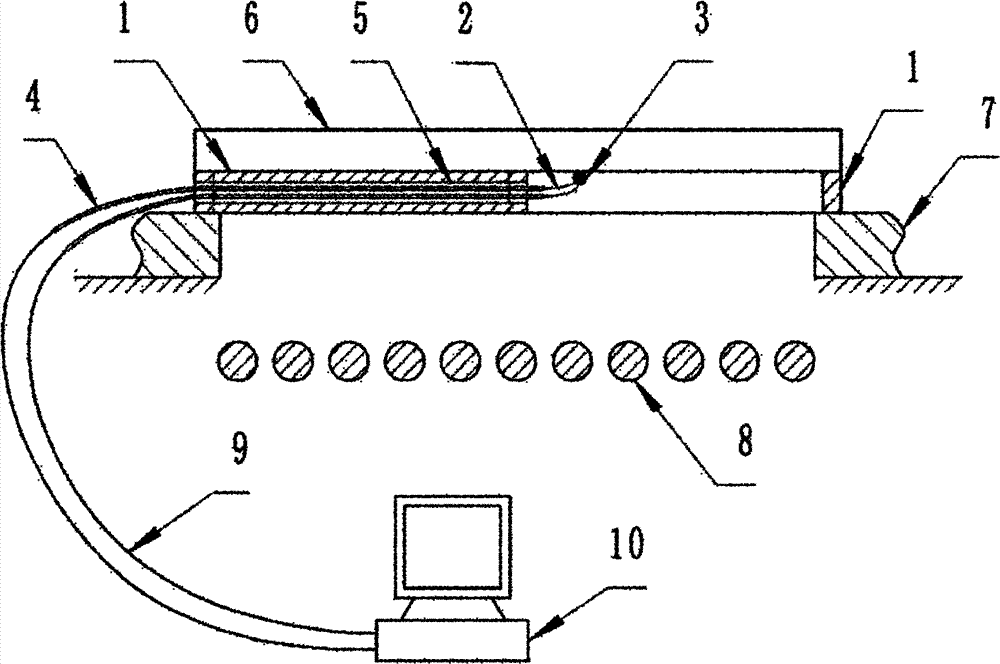

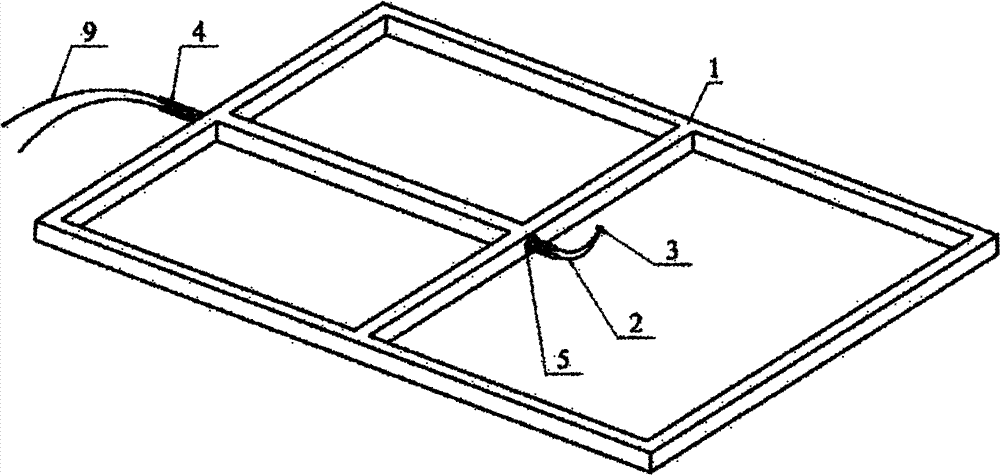

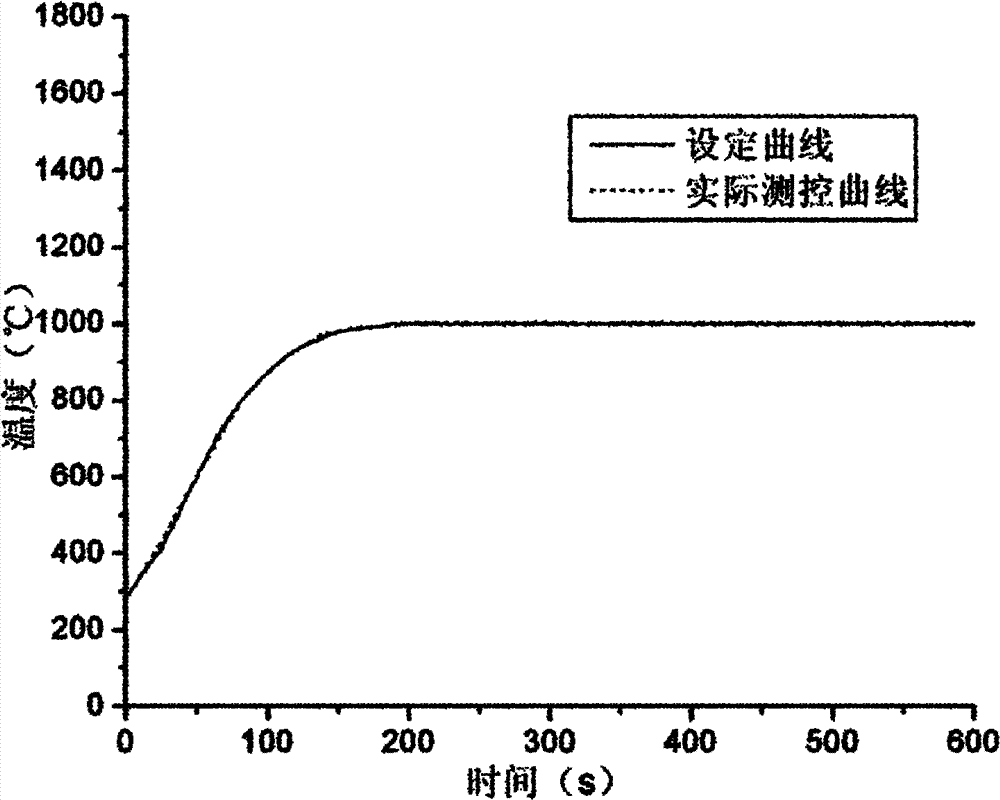

[0017] Such as figure 1 and figure 2 As shown, the present invention consists of a high-temperature ceramic frame 1, a temperature-measuring thermocouple 2, a flat plate test piece 6 of non-metallic heat-resistant material, a heat-insulating support frame 7, and a heating source 8 (the present embodiment adopts a silicon-molybdenum infrared heat source that can form a high-temperature environment of 1600° C. radiation heating tube), wire 9 and computer 10. The high-temperature ceramic frame 1 is made of corundum high-temperature ceramic material with a 1800°C-resistant alumina content of 99%, and the temperature-measuring thermocouple 2 uses a double platinum-rhodium thermocouple with a measuring range up to 1800°C. The high-temperature ceramic frame 1 is placed on the heat-insulating support frame 7. There is a round hole 5 on the high-temperature ceramic frame 1. The temperature-measuring thermocouple 2 covered with the ceramic insulating sleeve 4 is inserted into the roun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com