Noise tester of engine belt tightener

A technology for engines and tensioners, which is applied in the field of measuring instruments, can solve problems such as low detection efficiency, inconvenient online detection of tensioners, and inaccurate test results, so as to reduce installation difficulty, improve test efficiency, and improve test results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

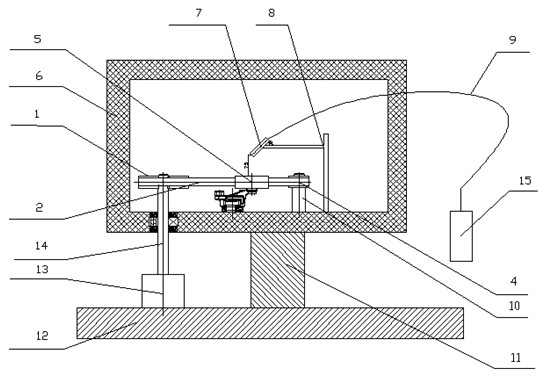

[0011] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0012] see image 3 , The tensioner noise tester includes a soundproof cover 6, a base 12, a sound level meter 15, a microphone 7, a stepper motor 13 and an engine train system, and the detected tensioner 5 is installed in the engine train system. The engine wheel train system and the microphone 7 are installed in the soundproof cover 6. The angle between the microphone 7 and the end face of the pulley of the tested tensioner 5 is 45 degrees, and the distance between the head of the microphone and the center of the tested tensioner pulley is 70mm. The output line of the microphone 7 is connected to the sound level meter 15 outside the soundproof cover, and the driving wheel 1 of the engine train system is connected with the stepper motor 13 outside the soundproof cover through the transmission shaft 14, and the stepper motor 13 and the soundproof cover 6 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com