Composite fly maggot feed

A feed, fly maggot technology, applied in animal feed, animal feed, application, etc., can solve the problems of insufficient fly maggot individuals, difficulty in collecting a large amount of feces, and poor production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

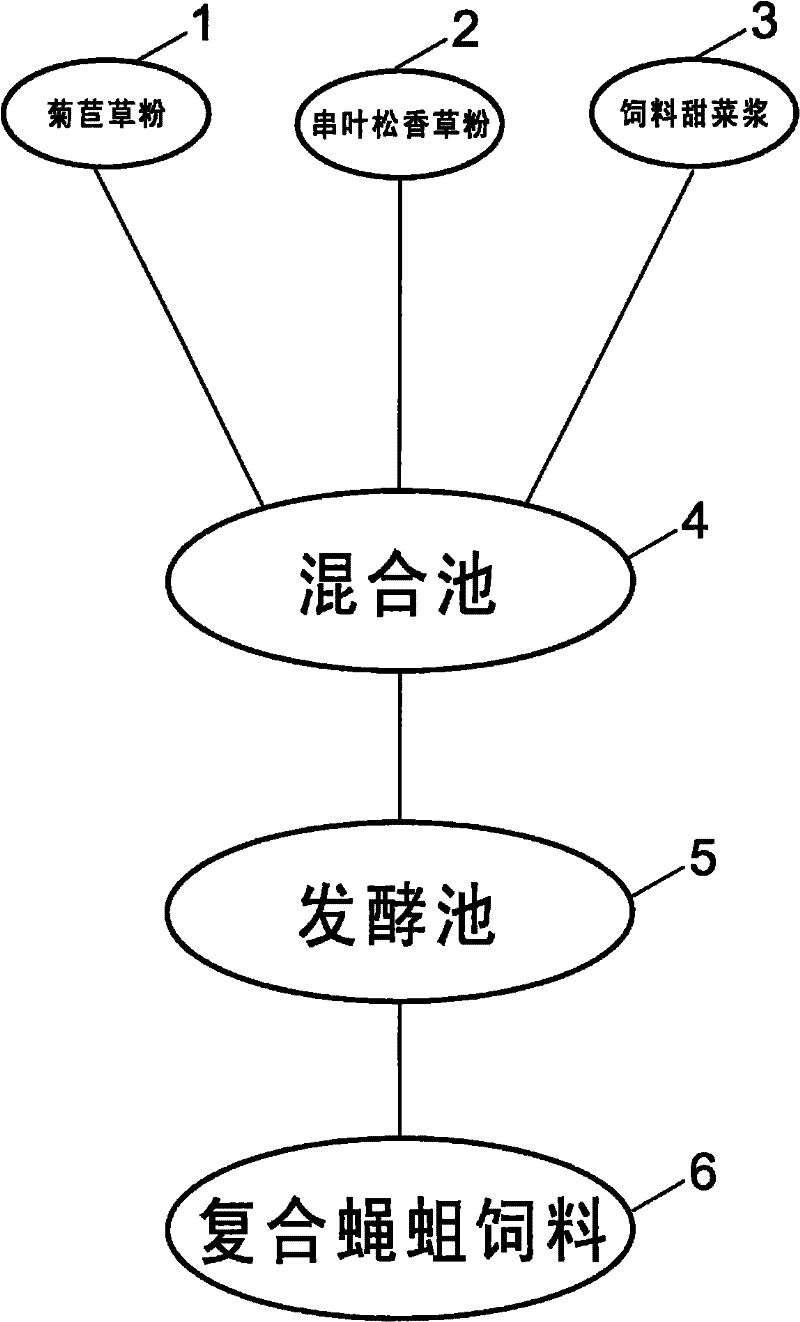

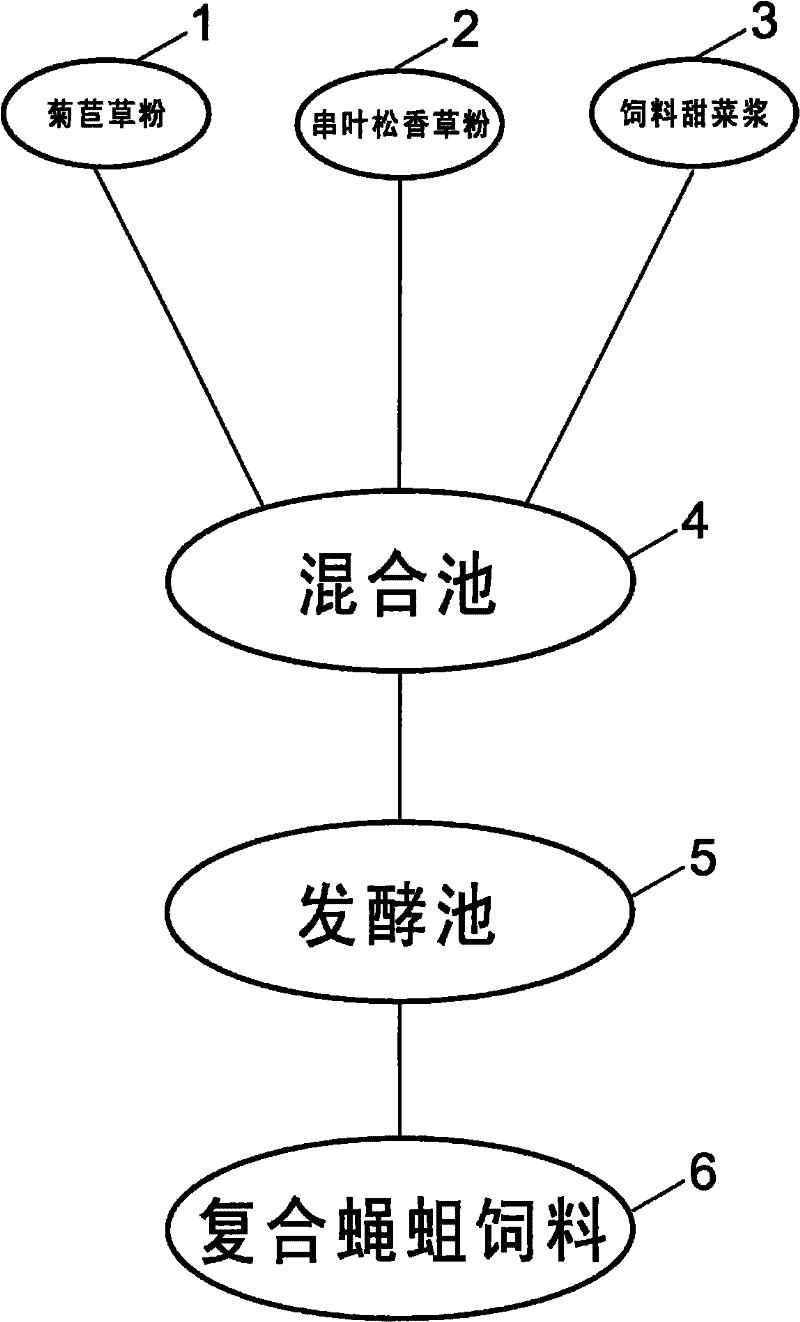

[0012] Chicory grass powder 1, cypress herb 2 and feed beet pulp 3 are put into the mixing tank 4 in a weight ratio of 3.75:3.75:2.5, and the mixing ratio can be determined according to the specific conditions of raw material resources. The fineness of chicory grass powder and cypress powder is below 240 mesh. After mixing evenly in the mixing tank 4, the humidity can be grasped so that it can be agglomerated by hand, and it can be dropped into the fermentation tank 5 for fermentation. The fermentation time is determined according to the indoor temperature. Generally, the fly maggot feed can be obtained by fermenting in the fermentation tank for 5 to 10 days.

[0013] The produced feed can be used as soon as it comes out, and the storage period should generally not exceed three days to prevent mildew. Can design the size of fermentation tank 5 according to the quantity of fly maggot in actual production. Generally, it is advisable to build 3 fermentation tanks for turnover. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com