Ironing slot of electromagnetic induction heated slotted ironing machine

A technology of electromagnetic induction heating and trough ironing machine, applied in induction heating, induction heating device, ironing machine and other directions, can solve the problems of unsatisfactory use effect of trough ironing machine and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

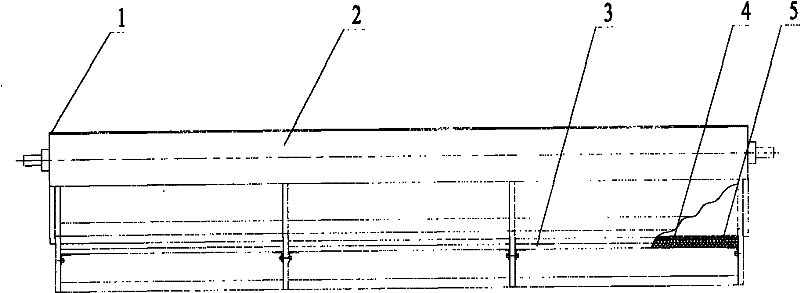

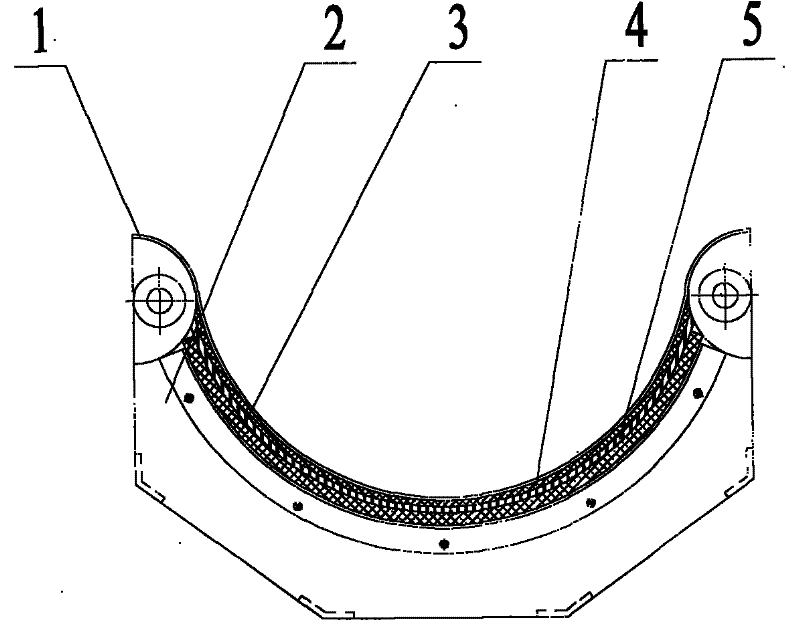

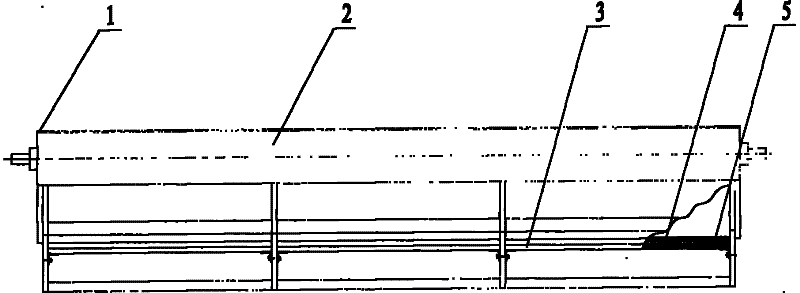

[0008] The figure includes a grooved arc plate 1, a base frame 2, a coil fixed arc plate 3, a buffer insulation layer 4, and an induction coil 5. It is characterized in that: both ends of the grooved arc plate 1 are welded on the base frame 2, and the arc surface Most of them are not connected with the base frame 2, there is a cavity between the grooved arc plate and the base frame, the induction coil 5 is installed on the inner arc surface of the coil fixed arc plate 3, and fixed by the coil fixed arc plate 3 through screws On the basic frame 2, the buffer insulation layer 4 is located between the outer arc surface of the groove-shaped arc plate 1 and the inner concave arc surface of the induction coil 5, which plays a role of heat preservation and accepts the deformation buffer of the groove-shaped arc plate 1, and the induction coil connects high frequency power supply.

[0009] The high-frequency power supply placed in the machine box can convert the industrial frequency p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com