Drive module and electronic apparatus

A technology of driving modules and driven bodies, which is applied in the direction of TV, electrical components, TV system components, etc., can solve the problems of inconsistency and defocusing, etc., with little possibility of achieving, suppressing the decline of manufacturing efficiency, and reducing the cost of defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] (drive module)

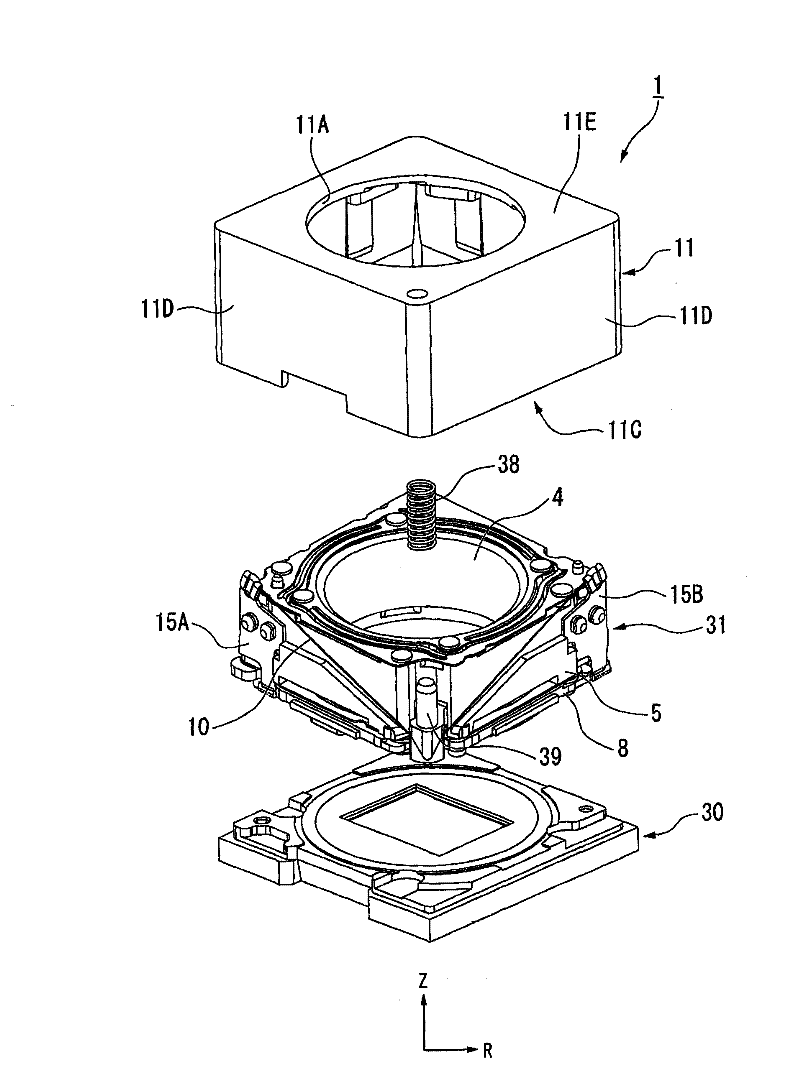

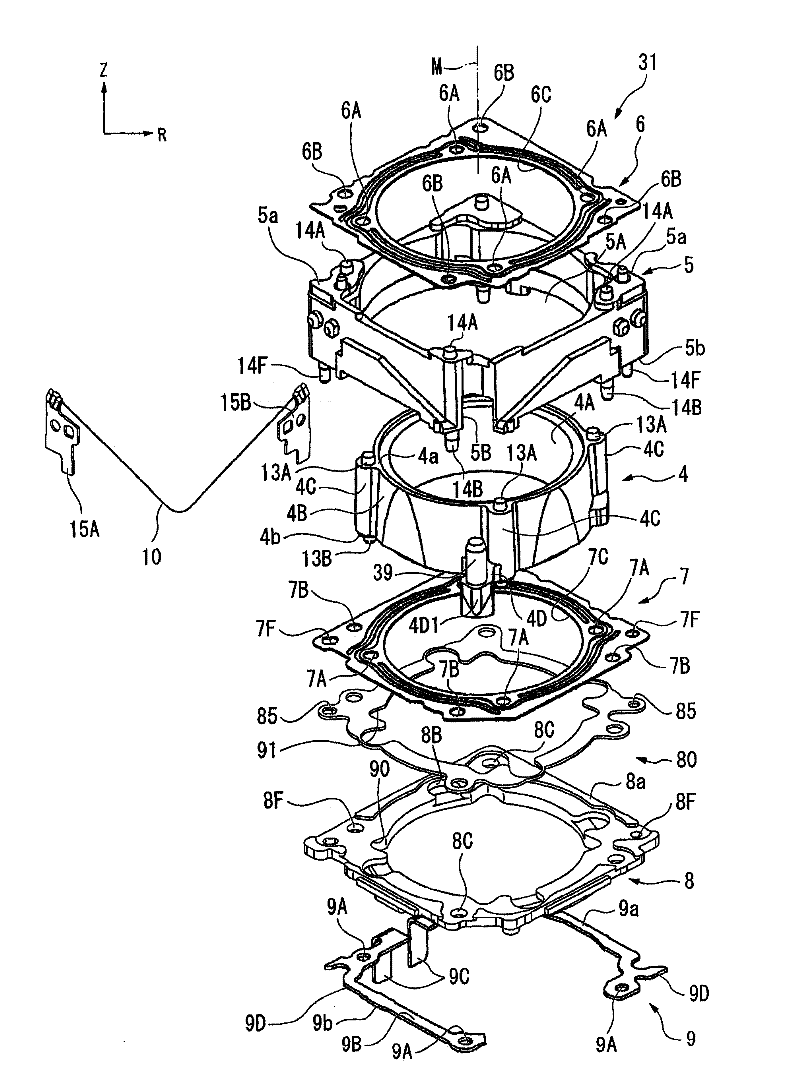

[0047] Hereinafter, an embodiment of the drive module of the present invention will be described based on the drawings. In this embodiment, the driving module of the imaging lens unit of the camera is taken as an example for description. In addition, as an example of the actuator for driving the lens unit, a case where a shape-memory alloy wire is used will be described as an example. In addition, in each of the following figures, the axial direction of the lens unit may be referred to as the Z direction, and the radial direction may be referred to as the R direction.

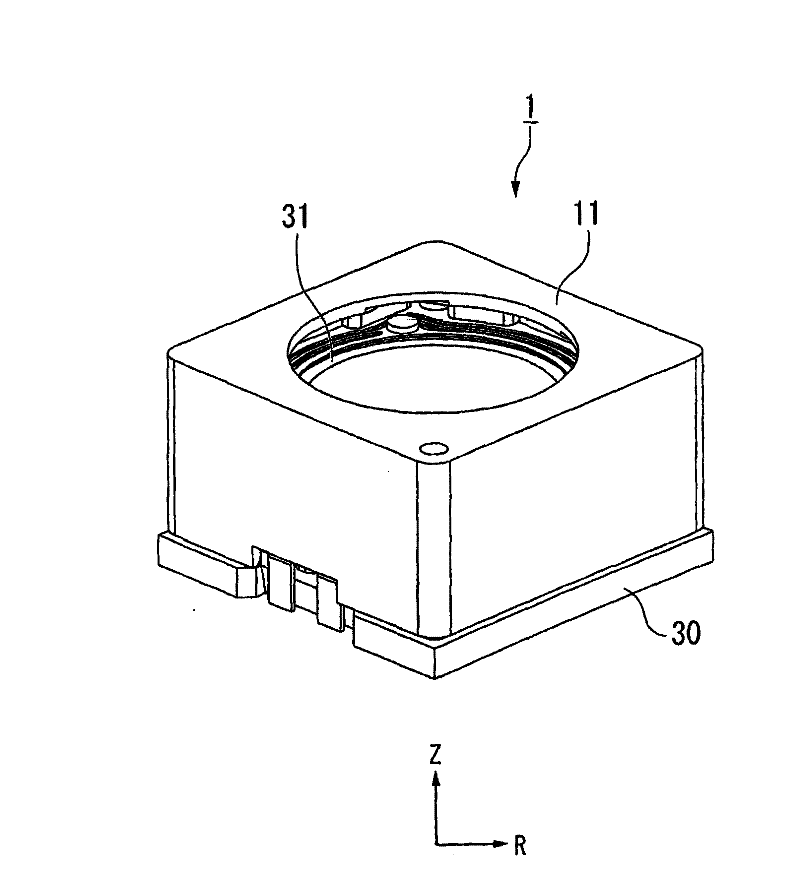

[0048] figure 1 It is an external perspective view of the drive module 1 . figure 2 It is an exploded perspective view showing a schematic structure of the drive module 1 . Such as figure 1 with figure 2 As shown, the drive module 1 of the present embodiment is configured in a box shape as a whole.

[0049] After the drive module 1 is assembled, it is fixed on a substrate that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com