Fixed improved structure of vacuum tube of alternating current vacuum contactor

A technology of vacuum contactor and improved structure, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., which can solve the problems of short arcing time, inconvenient installation, and high working voltage, and achieve cost reduction and simplification. structure, effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

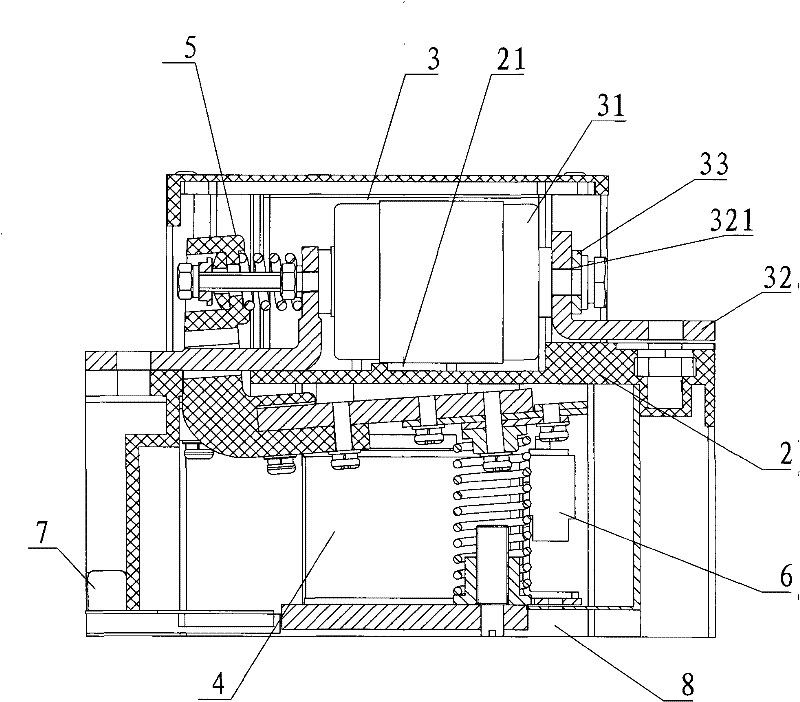

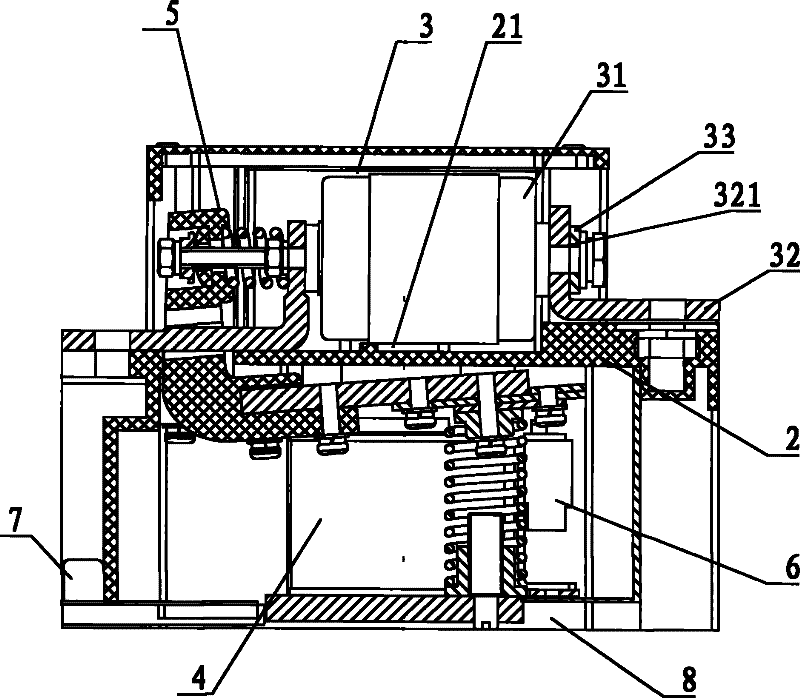

[0009] Embodiment: An improved structure for fixing the vacuum tube of an AC vacuum contactor. The AC vacuum contactor is composed of an insulating frame 2, a vacuum arc extinguishing device 3, an electromagnetic system 4, a transmission mechanism 5, an auxiliary switch system 6, a terminal 7 and a base 8, the vacuum arc extinguishing device 3 includes a vacuum tube 31 and a conductive plate 32, the vacuum tube 31 is fixedly embedded in the groove 21 on the upper end of the insulating frame, one end of the vacuum tube 31 is connected to the transmission mechanism 5, and the other end of the vacuum tube 31 is connected to the conductive plate 32, the conductive plate is connected by the side and the bottom in an "L" shape, the side of the conductive plate 32 connected to the other end of the vacuum tube is provided with a through hole 321, and the side of the conductive plate 32 is fixed through the through hole 321 At the other end of the vacuum tube 31; on the insulating frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com