Packaging structure of light-emitting diode emitting light in forward direction and formation method thereof

A light-emitting diode, forward light-emitting technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of rising product cost and product volume, and achieve the effect of increasing heat dissipation effect, improving luminous effect and life time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The packaging structure and method of forward-emitting light-emitting diodes provided by the present invention will be described in detail below in conjunction with illustrations and embodiments.

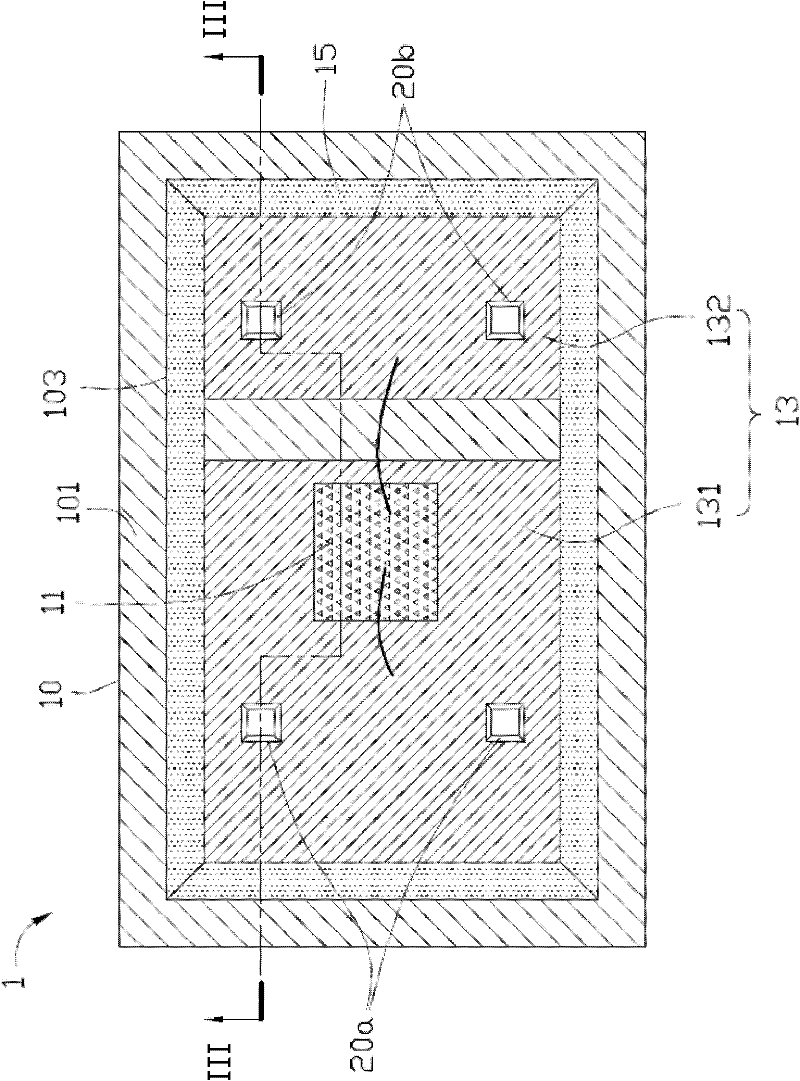

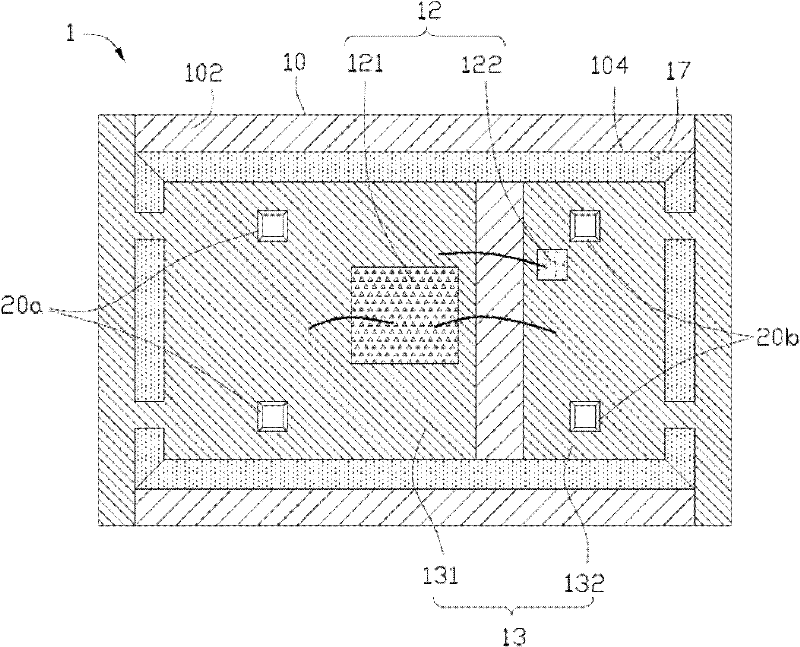

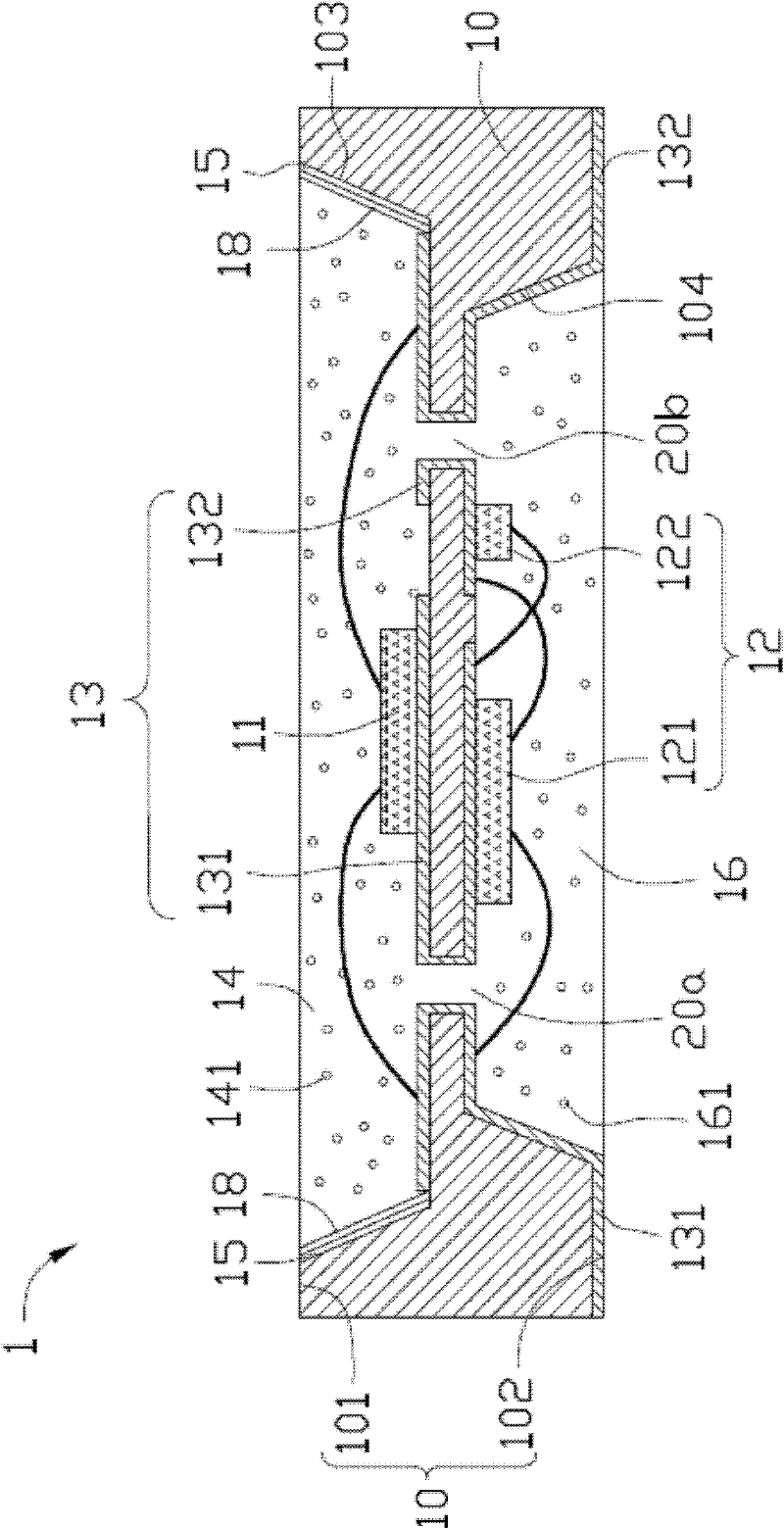

[0047] The first embodiment of the present invention provides a packaging structure 1 of a first forward-emitting semiconductor light-emitting component, please refer to Figure 1A , Figure 1B as well as Figure 1C . The package structure 1 of the above-mentioned first forward-emitting semiconductor light-emitting component includes a silicon substrate 10 , a first semiconductor component 11 , a second semiconductor component 12 and a circuit structure 13 . The above-mentioned silicon substrate 10 includes a first surface 101 and a second surface 102 , and the first surface 101 and the second surface 102 are respectively located on opposite sides of the silicon substrate 10 . The first surface 101 is the light-emitting surface of the packaging structure of the semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com