Method and device for secondarily distributing steam-pressing bricks

A technology of secondary distribution and autoclaved bricks, which is applied to supply devices, manufacturing tools, etc., to achieve the effects of uniform thickness, reduced consumption, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Best practice:

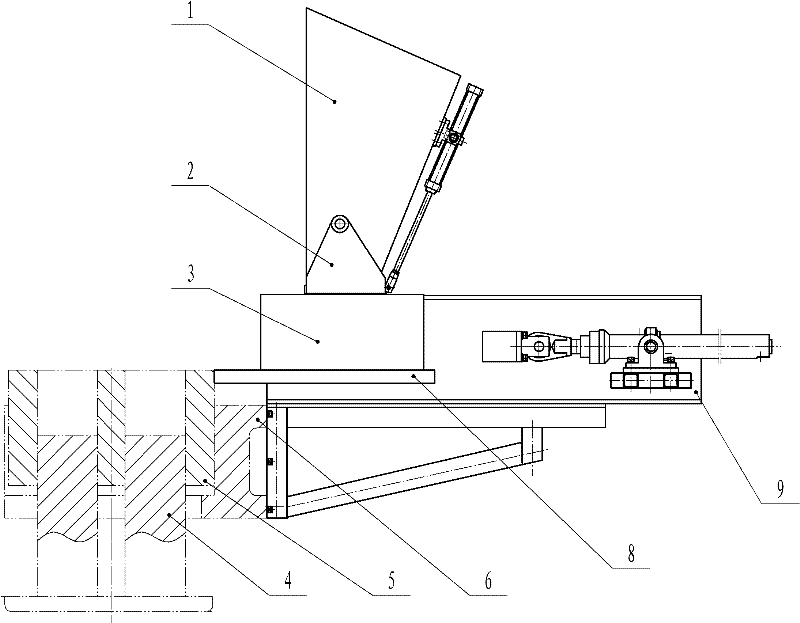

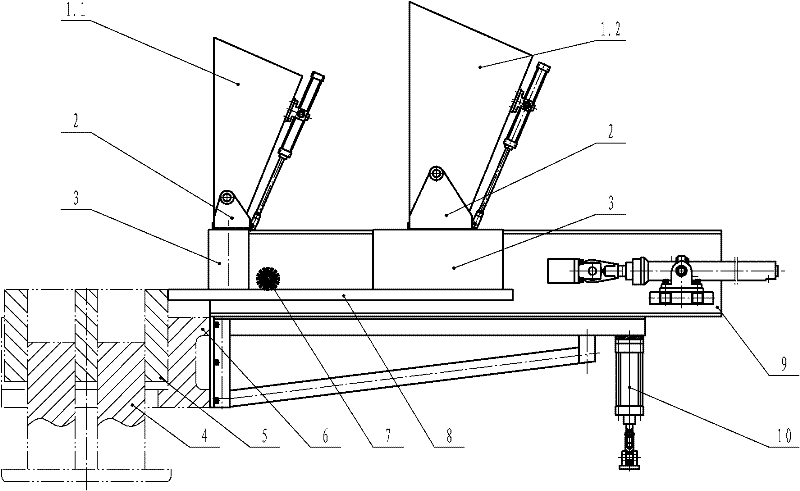

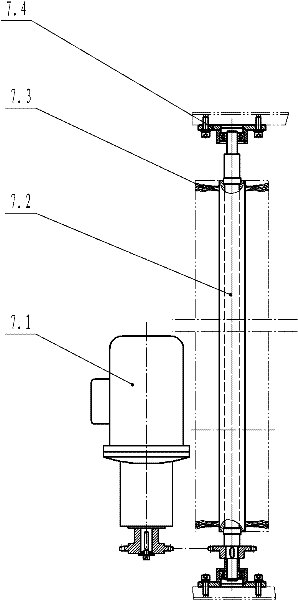

[0033] like figure 2 , image 3 , a secondary distributing device for autoclaved bricks, the key points of its composition are that it includes a base material hopper 1.2, a fabric hopper 1.1, a fixed supporting plate 8 and a material distributing cart 9, and the bottoms of the fabric hopper 1.1 and the base material hopper 1.2 are respectively provided with feeding controls. The hopper door 2, fabric hopper 1.1 and base material hopper 1.2 all have their own stirring mechanism 3, and there is a sealing strip at the bottom of the stirring mechanism 3. Before the press reaches the cloth position, the sealing strip at the bottom of the stirring mechanism 3 and the fixed support Plate 8 contacts to prevent powder leakage, fabric hopper 1.1 and base material hopper 1.2 are installed on the fabric frame, respectively equipped with different powder, fabric hopper 1.1 is in front and is closer to the mold than base material hopper 1.2, fabric vehicle 9 Driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com