Workpiece clamping mechanism of multi-wire cutting machine

A technology of multi-wire cutting machine and clamping mechanism, which is applied to work accessories, manufacturing tools, stone processing equipment, etc., and can solve problems such as stress concentration, uneven surface of silicon crystal rods, and affecting processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

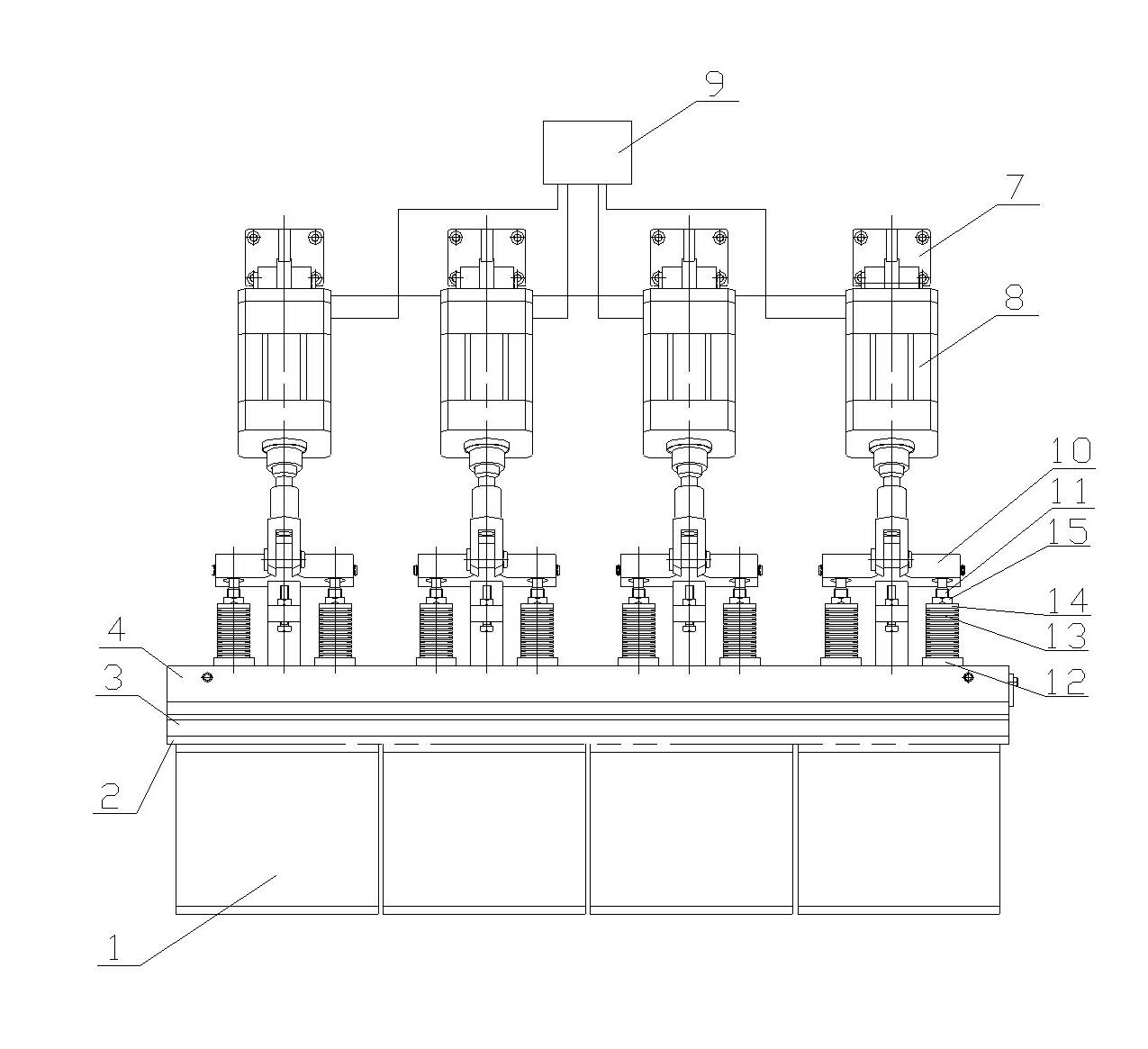

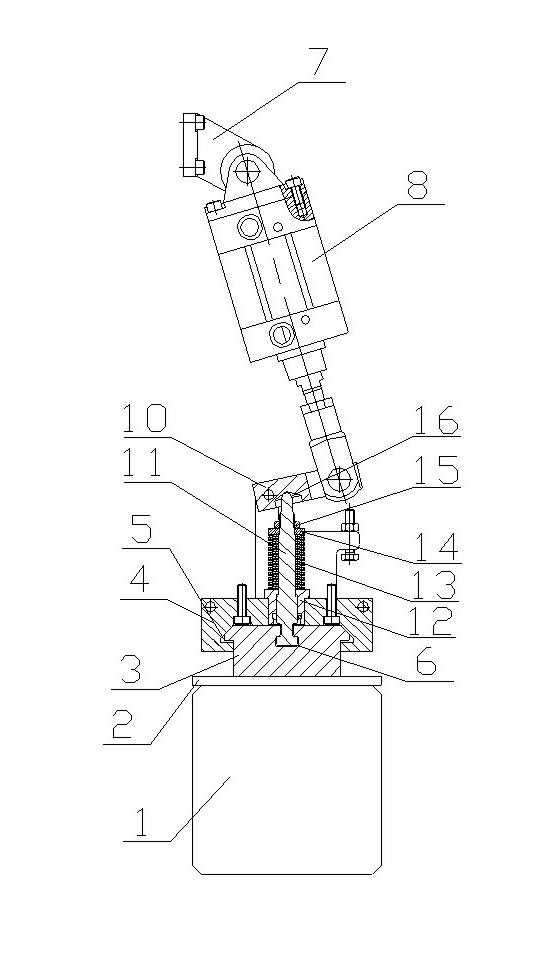

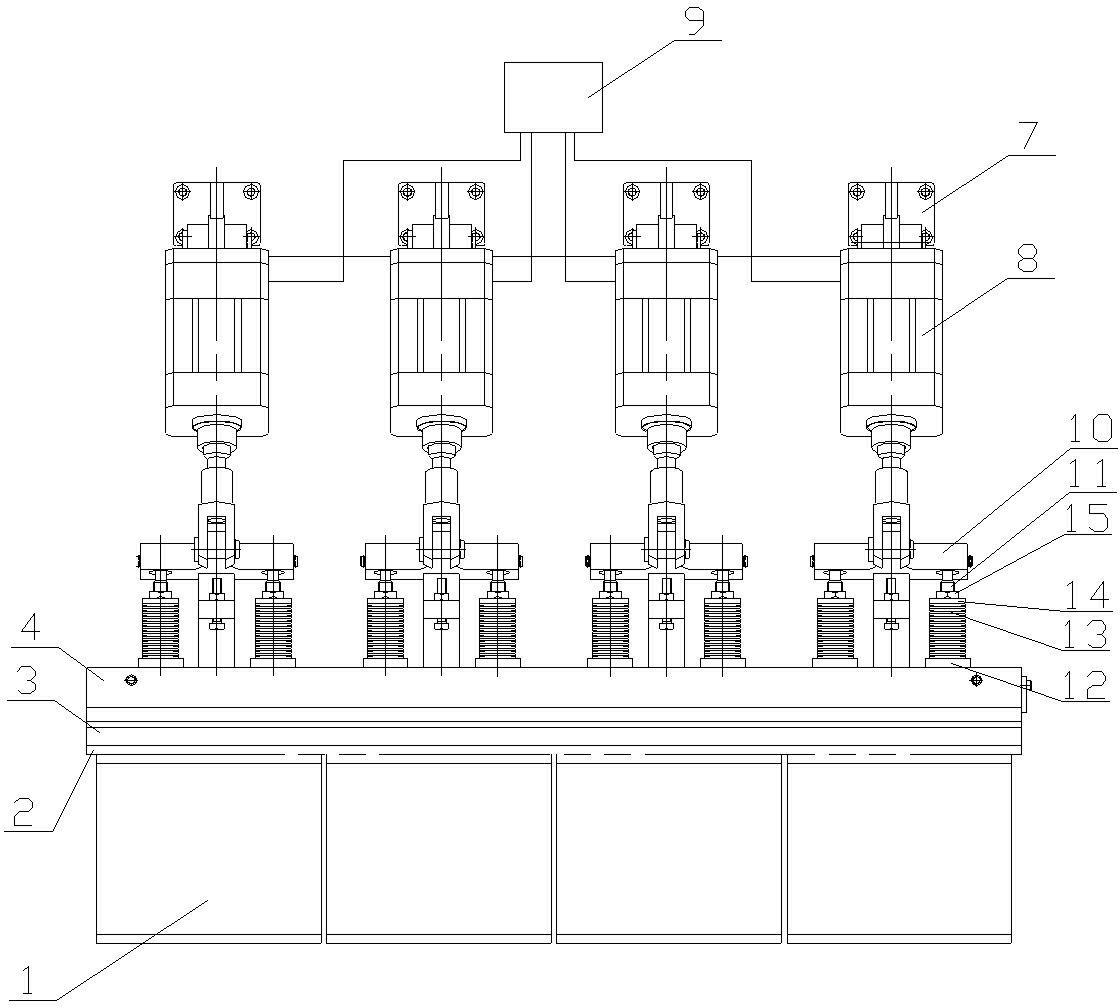

[0009] See figure 1 , figure 2 , the upper surface of the silicon ingot 1 is close to the glass plate 2, the upper surface of the glass plate 2 is fastened to the lower lifting plate 3, and the upper part of the lower lifting plate 3 is inserted into the linear installation groove 5 of the upper lifting plate 4 , the position of the upper lifting plate 4 is fixed, the cross-section of the linear installation groove 5 is trapezoidal and the bottom is open, the center of the upper end face of the lower lifting plate 3 is provided with a large lower and upper small linear groove body 6, and the upper part of the upper lifting plate 4 is Double clevis seats 7 are arranged, the positions of the evenly distributed double clevis seats 7 are fixed, the lower part of each double clevis seat 7 is connected with a cylinder 8, the cylinder 8 is connected with the same pneumatic valve 9, and the top rod of the cylinder 8 is connected with the lower bracket 10, Both sides of the lower bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com