Method for preparing large-area nano-metal photonic crystal by hot-pressing printing

A photonic crystal and nano-metal technology, which is applied in optics, optical components, opto-mechanical equipment, etc., can solve the problems that the spatial size of the light spot cannot be too large, it is difficult to prepare metal nanostructures, and the quality of metal photonic crystals is affected, and the preparation cycle is achieved. Short, simple process, easy to emboss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Use indium tin oxide (ITO) glass as a substrate, ultrasonically in acetone and ethanol for 15 minutes to remove dust and oil on the surface, and place it on a heating platform with a temperature of 100°C.

[0026] 2) Select gold nanoparticles coated with hexanethiol, use xylene as the solvent, prepare a gold solution with a concentration of 100 mg / ml, and sonicate for 15 minutes to prevent the nanoparticles from agglomerating.

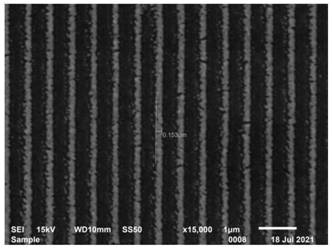

[0027] 3) Take 10 μl of the metal nanoparticle solution configured in step 2) and drop it on the ITO substrate in step 1) (the side coated with the ITO film faces up), and while the metal nanoparticle solution is still wet, use a 600nm cycle The PDMS grating is used as a template. When pressing, ensure that the direction of the grating lines is parallel to the direction of the pressing force, the pressure is 10N, and the pressing time is 1 min.

[0028] 4) Remove the embossed template and ITO substrate from the heating table at the same time,...

Embodiment 2

[0031] 1) Indium tin oxide (ITO) glass was used as the substrate (same as Example 1), ultrasonicated in acetone and ethanol for 15 minutes to remove dust and oil on the surface, and placed on a heating table with a temperature of 100°C.

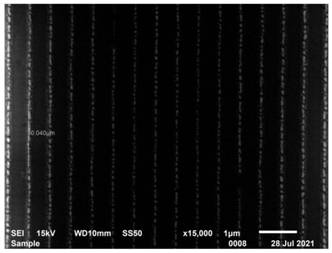

[0032] 2) Select gold nanoparticles coated with hexanethiol, use xylene as the solvent, prepare a gold solution with a concentration of 50 mg / ml, and sonicate for 15 minutes to prevent the nanoparticles from agglomerating.

[0033] 3) Take 10 μl of the metal nanoparticle solution configured in step 2) and drop it on the ITO substrate in step 1) (the side coated with the ITO film faces up), and while the metal nanoparticle solution is still wet, use a 600nm cycle The PDMS grating is used as a template. When pressing, ensure that the direction of the grating lines is parallel to the direction of the pressing force, the pressure is 10N, and the pressing time is 1 min.

[0034] 4) Remove the embossed template and ITO substrate in step 3) from the...

Embodiment 3

[0037] Below in conjunction with embodiment further illustrate the present invention, but the present invention is not limited to this embodiment.

[0038] The invention discloses a method for preparing a large-area nanometer metal grating by hot embossing, and the specific implementation example 3 is as follows:

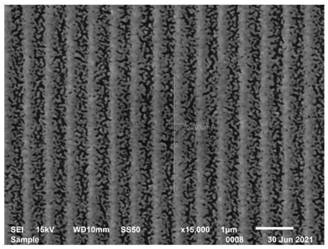

[0039] 1) Use indium tin oxide (ITO) glass as a substrate, ultrasonically in acetone and ethanol for 15 minutes to remove dust and oil on the surface, and place it on a heating table with a temperature of 110°C.

[0040] 2) Select gold nanoparticles coated with hexanethiol, use xylene as solvent, prepare a gold solution with a concentration of 150 mg / ml, and sonicate for 15 minutes to prevent the nanoparticles from agglomerating.

[0041] 3) Take 10 μl of the metal nanoparticle solution configured in step 2) and drop it on the ITO substrate in step 1) (the side coated with the ITO film faces up), and while the metal nanoparticle solution is still wet, use a 600nm cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com