Brake control device directly driven by permanent magnet synchronous motor for automatic staircase

A permanent magnet synchronous motor and escalator technology, applied in escalators, brake actuators, transportation and packaging, etc., can solve the problems of reducing manufacturing and maintenance costs, and the braking torque cannot meet the braking distance requirements at the same time, to achieve Reduce manufacturing and maintenance costs, promote wide application, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

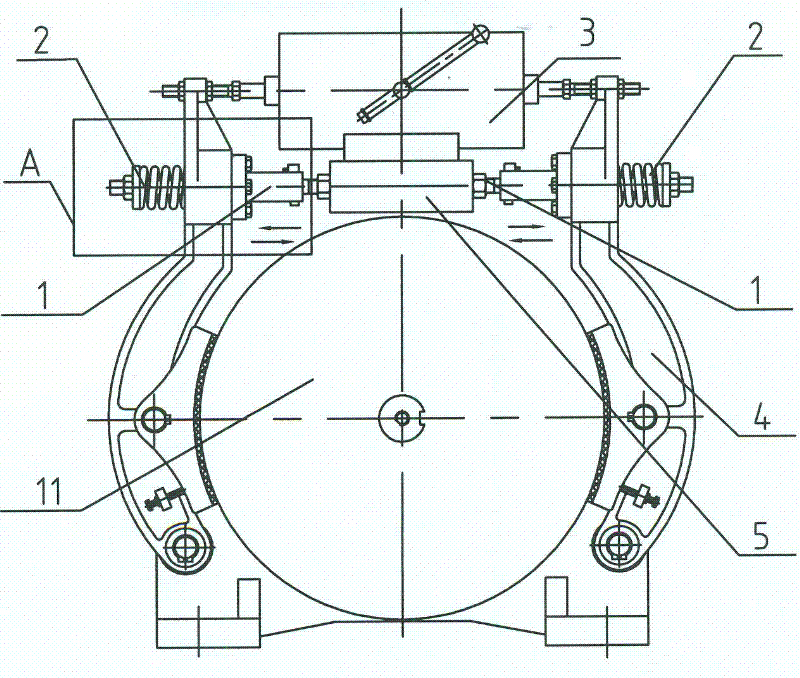

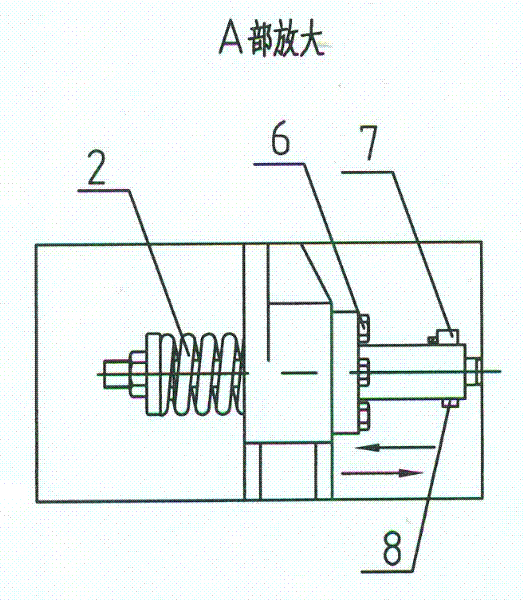

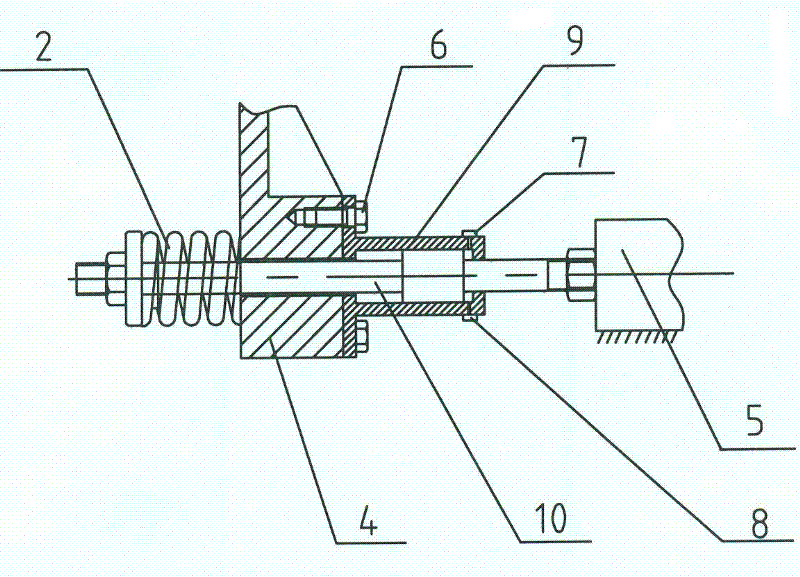

[0013] according to Figures 1 to 3 The specific structure of the present invention will be described in detail. The braking control device of the permanent magnet synchronous motor directly driving the escalator includes an electromagnetic brake 3, a brake arm 4 with a compression spring 2 and a brake shoe assembled on the outer periphery of the brake disc 11, a self-balancing cylinder 1 and the like. A self-balancing air cylinder 1 for controlling the braking torque of the braking arm 4 is arranged between the two ends of the fixing seat 5 of the electromagnetic brake 3 and the inner side of the braking arm 4 respectively. The cylinder body 9 of the self-balancing cylinder 1 is fixed on the inner side of the brake arm 4 through the connecting bolt 6 . One end of the piston rod 10 of the self-balancing cylinder 1 is connected to the end of the fixed seat 5, and the other end of the piston rod 10 is assembled on the outside of the brake arm 4 through the compression spring 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com