Transmission gear system of motor vehicle

A technology for transmission gears and motor vehicles, which is applied to transmission devices, gear transmission devices, belts/chains/gears, etc. It can solve the problems of high cost, complex structure, and small range of speed change adjustment, and achieve low cost and high cost performance , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

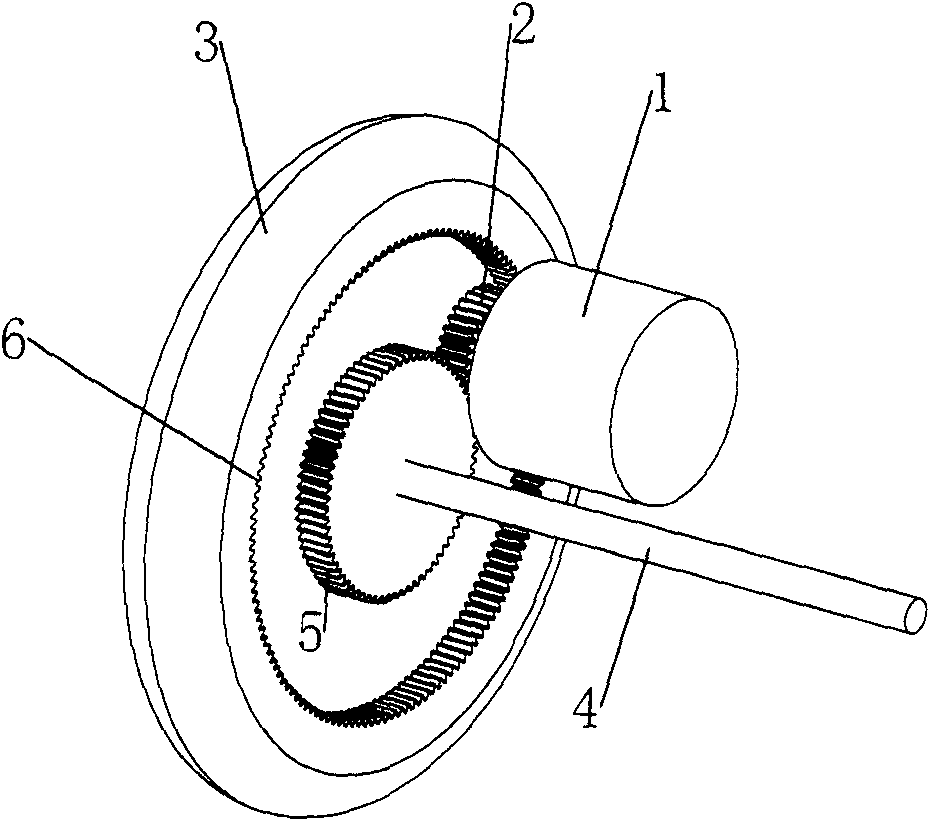

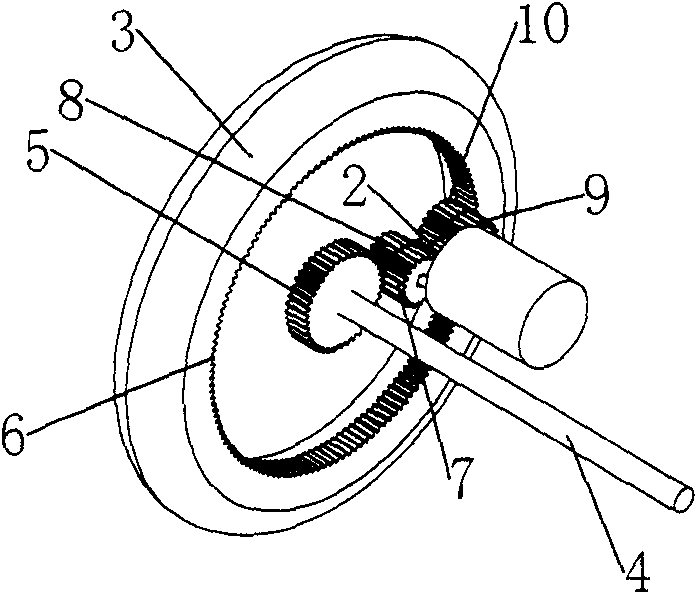

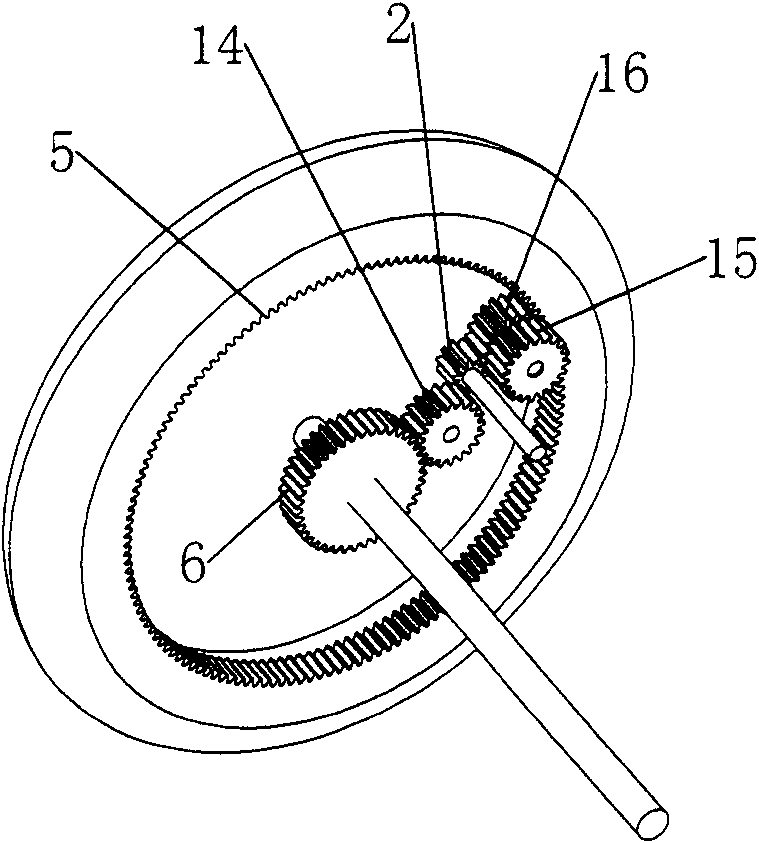

[0015] Such as figure 1 As shown, the first embodiment of the motor vehicle transmission gear system of the present invention includes a drive motor 1, a drive gear 2 is arranged on the drive shaft of the drive motor 1, an external gear 5 is arranged around the wheel shaft 4 on the wheel 3, and an external gear 5 is arranged on the wheel 3. 1. An internal gear 6 is arranged on the periphery of the external gear 5, and the drive gear 2 drives the internal gear 6 or the external gear 5, and the internal gear 6 or the external gear 5 drives the wheels to rotate. The outer gear 5 and the wheel 3 are connected and cooperated through the one-way clutch, and the inner gear 6 and the wheel 3 are connected and cooperated through the one-way clutch. 2 directly meshes with internal gear 6 and external gear 5.

[0016] The following briefly describes the operation mode of the motor vehicle transmission gear system in the first embodiment: 1. The driving motor 1 rotates forward (the so-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com