Roller transmission device

A transmission device and roller technology, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of low efficiency, cannot be made into high-power and low-speed motor, etc., and achieves simple structure, coaxial output, The effect of reducing the radial force component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

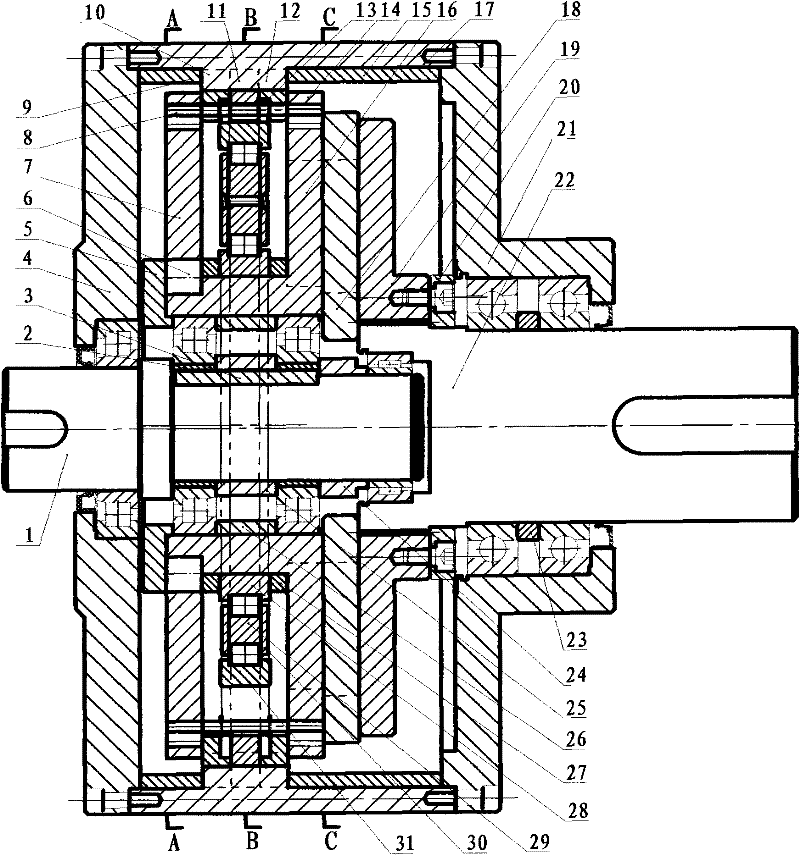

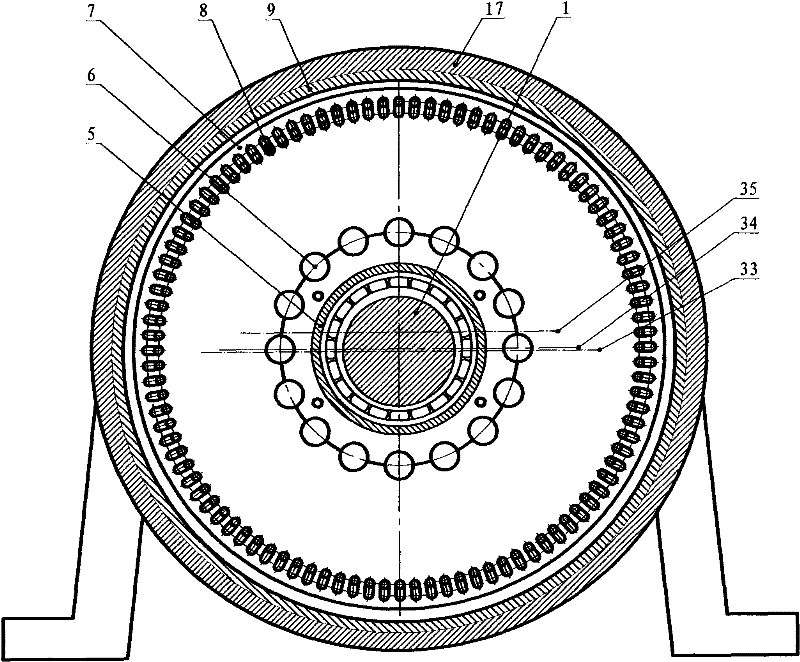

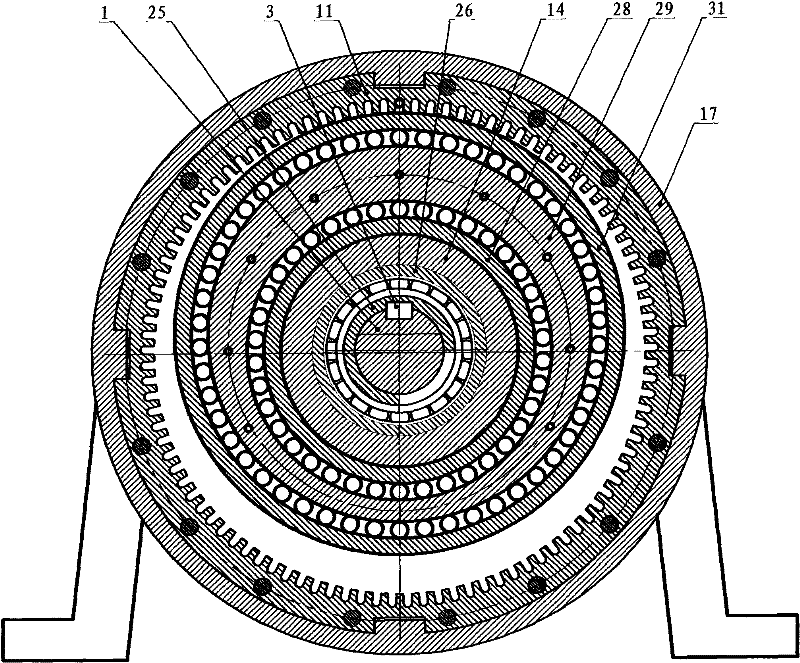

[0026] Examples of the present invention figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0027] The input shaft [1] is formed by superimposing the cylinder at the left end, the shaft shoulder and the cylinder at the right end. All cylinders except the shaft shoulder are machined with keyways. A groove for mounting a shaft retaining ring is machined at the far right end. The input shaft can also be directly made into a shaft shoulder, and the centerlines of the left and right ends coincide, and the centerlines of the supporting left and right sheave positions do not coincide with the centerlines of the left and right ends. Using this measure can cancel the eccentric sleeve [2].

[0028] The eccentric sleeve [2] is superimposed by an outer cylinder and an inner hole whose centerlines do not overlap, and a keyway is processed in the hole.

[0029] Flat key [3] is installed on the input shaft [1] and connects the hexahedron of eccentric sleeve [2].

[0030] Left cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com