Light-emitting diode (LED) bulb lamp structure

A technology of LED bulb lamps and LED modules, which is applied in the direction of lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of reducing the working life of power supply and LED modules, and increasing the temperature, so as to improve the working life and reduce the temperature. Effect of Operating Temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

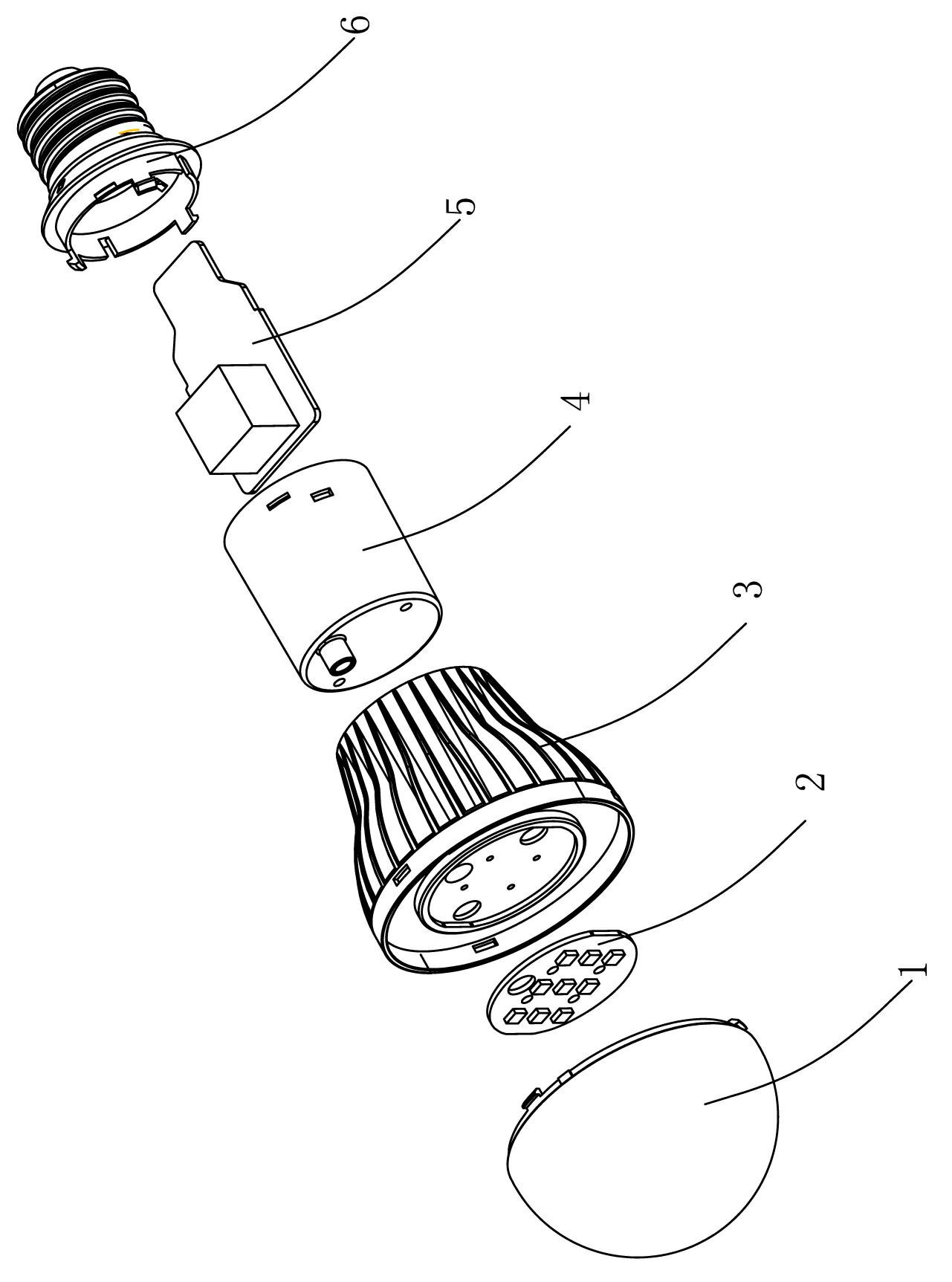

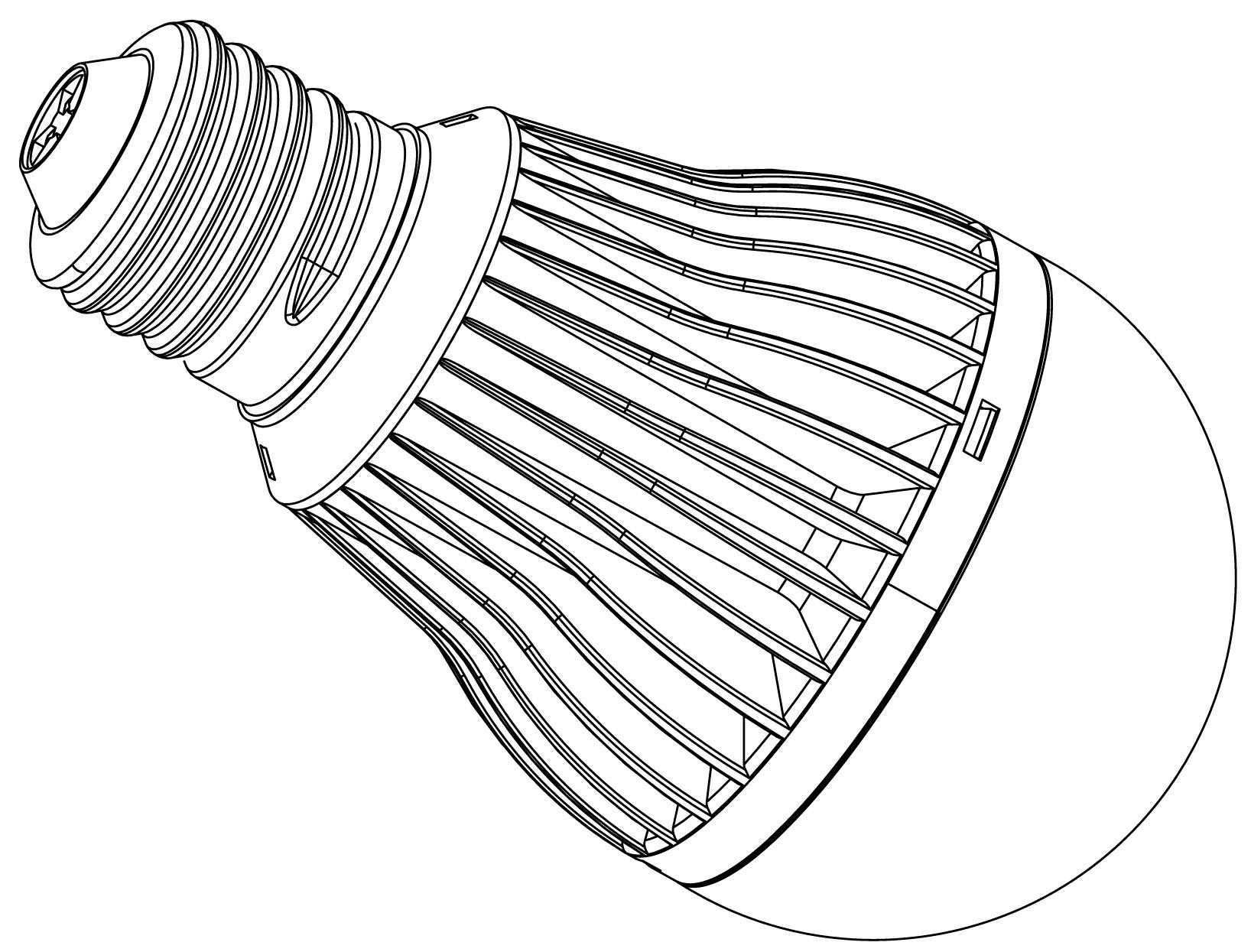

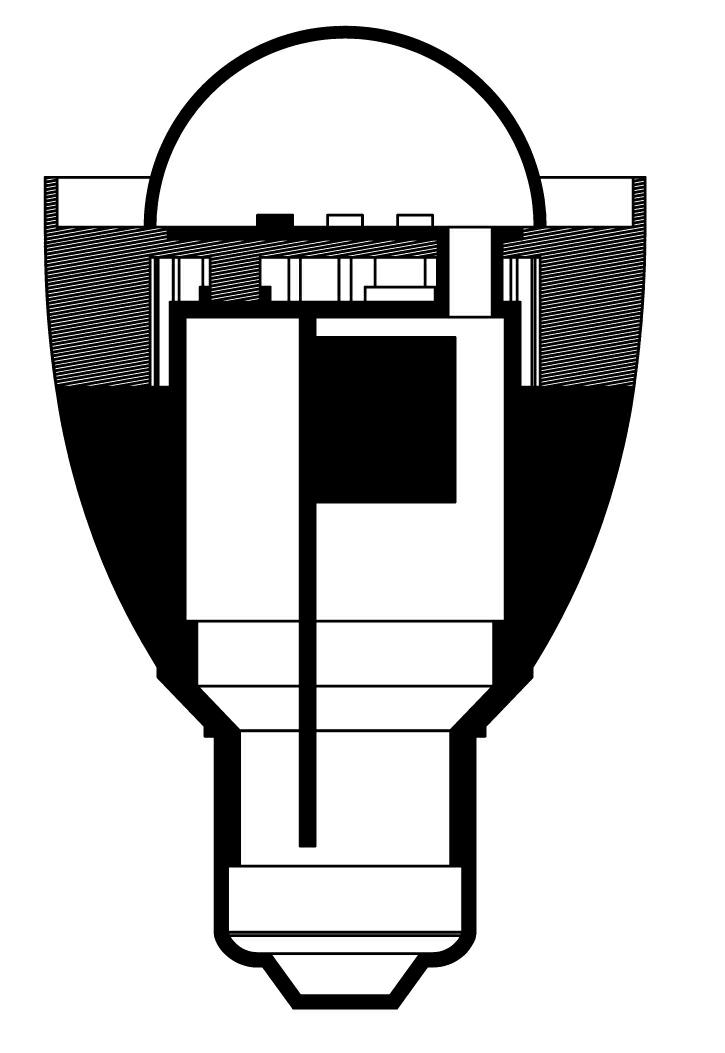

[0021] refer to image 3 and Figure 4 , an LED bulb lamp structure, comprising a lamp base 6, the lamp base 6 is sequentially provided with a lamp base lining 8, a driving power supply 5, a power radiator 7, and an LED module radiator 3, and the driving power supply 5 and the power radiator 7 tightly connected, the LED module radiator 3 is installed with the LED module 2 and the lampshade 1, and there is a gap between the LED module radiator 3 and the power radiator 7 or the heat insulation connection is made through a heat insulating material.

[0022] As a further preferred embodiment, thermal conductive glue is filled between the power radiator 7 and the driving power 5 .

[0023] As a further preferred embodiment, the LED module heat sink 3 is cylindrical or rectangular.

[0024] As a further preferred embodiment, the power radiator 7 is in the shape of a cylinder or a cuboid.

[0025] As a further preferred embodiment, the material of the LED module heat sink 3 is alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com