Improvement of press-in type air-conditioning control system for weaving

A control system and air conditioning technology, applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve the problems of high local relative humidity, increase in coal consumption, increase in coal consumption, etc., and improve the working environment of the workshop , The effect of improving product quality and working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

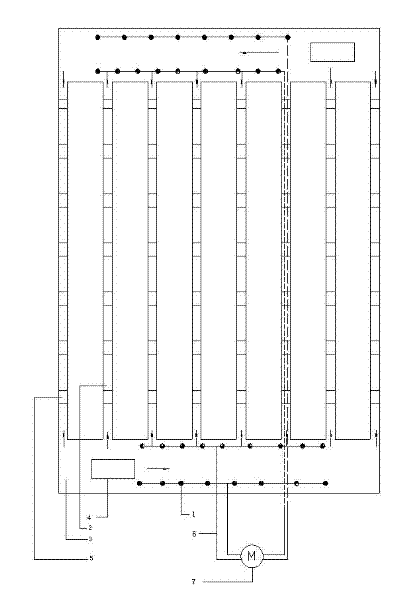

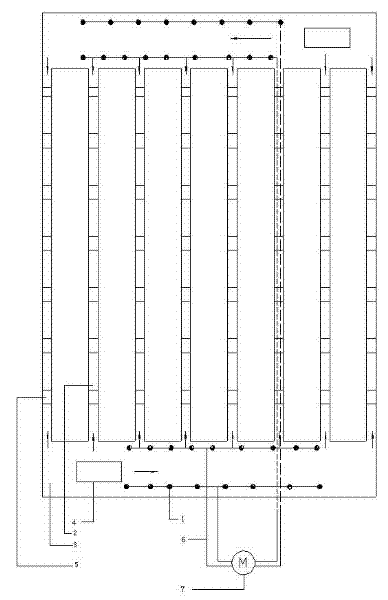

[0012] Such as figure 1 shown. The present invention includes a steam conveying device, a spray chamber water mist generating device, a main air duct 3, a branch air duct 2 and a humidifying device 7, which are prior art. The humidifying device 7 includes a high-pressure pump, a humidifier pipeline, a water heating device, a humidifier nozzle and a temperature and humidity control device. The main air duct 3 is located at the top of the longitudinal two sides of the workshop, and the main air duct 3 is provided with a main air duct air supply port 4 . A plurality of branch air ducts 2 are connected between the two main air ducts 3 , and branch air duct air outlets 5 are evenly arranged on the branch air ducts 2 . The steam conveying device is connected with the air supply port 4 of the main air duct through a pipeline. The feature of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com