Fast-heating type water heating device

A water heating device, fast heating technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of reduced reaction sensitivity, oscillation, large distance, etc., to achieve low flow resistance and controllable temperature Good performance and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

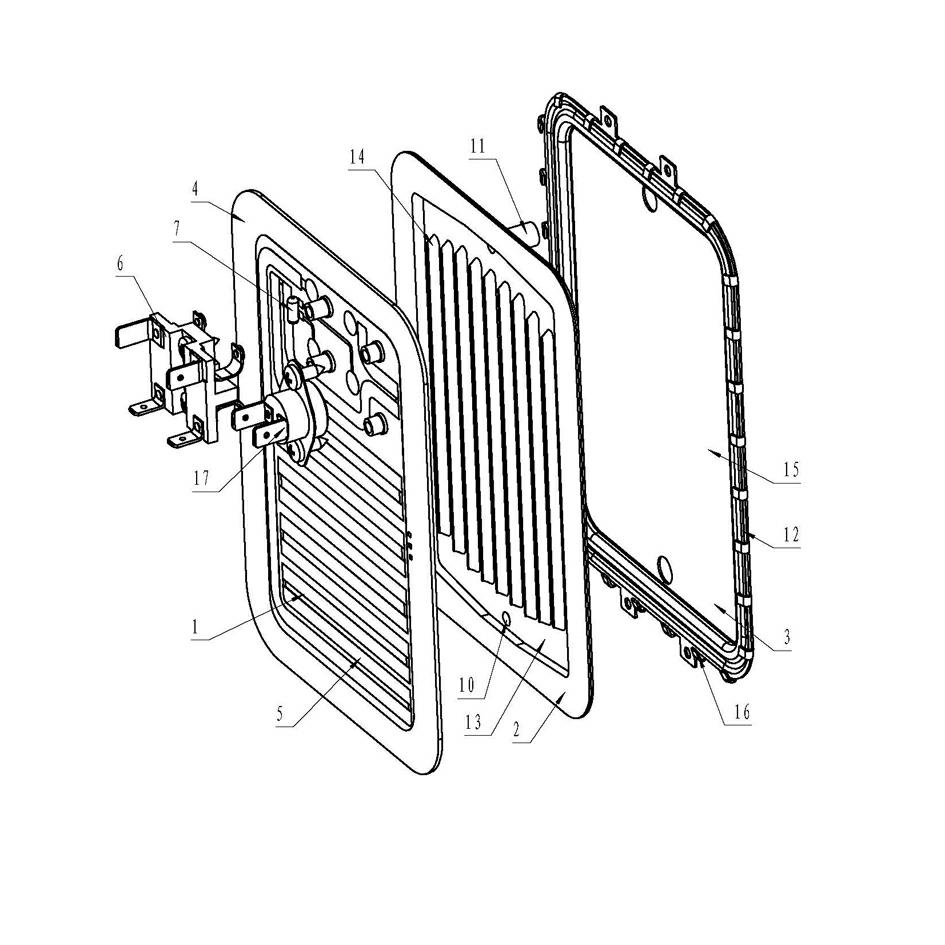

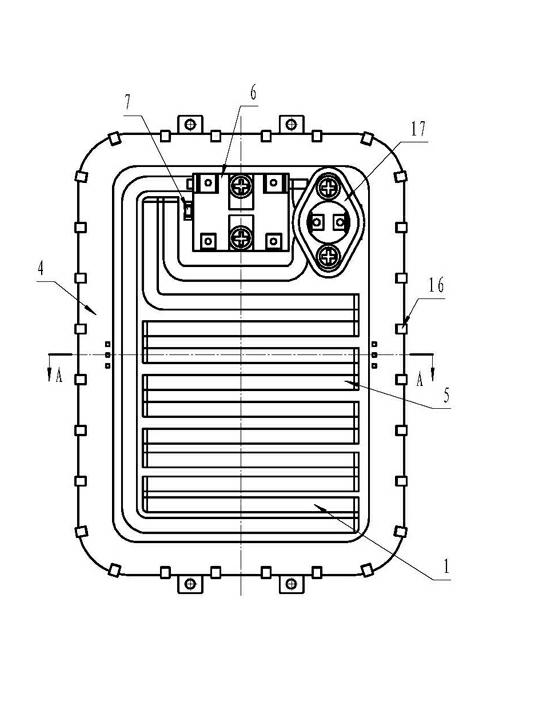

[0019] The embodiment of the present invention is mainly composed of an electric heating film heating plate 1, a water channel plate 2, a heating body rear plate 3, a temperature controller 17, a thermistor 7, a water inlet 10 (pipe), a water outlet 11 (pipe), and a control circuit. The electrothermal film heating plate 1 and the heating body rear plate 3 clamp the water channel plate 2 through several tooth-shaped installation buckles 16 around the heating body rear plate 3, and are bent and sealed as a whole. A water channel cavity 9 that allows water to flow is formed between the water channel grid 14 and the electric heating film heating plate 1. The shape of the cavity guides the flow of water. The water inlet 10 (pipe) and the water outlet 11 (pipe) are located The upper and lower ends of 2 are drawn from the water channel plate 2 through the heating body rear plate 3. The water channel plate 2 is rectangular, and the grille 14 arranged on it is S-shaped, forming a series...

Embodiment 2

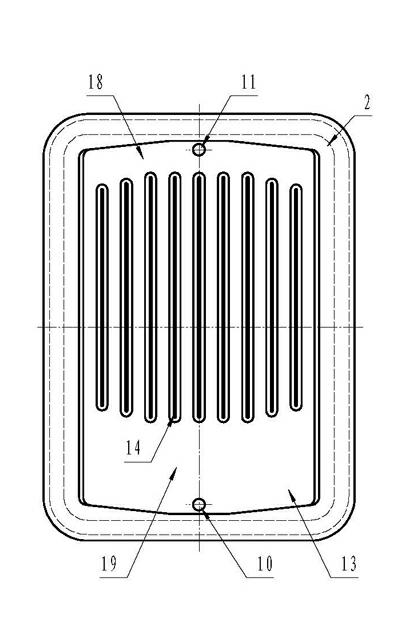

[0021] The water channel plate 2 described in this embodiment is rectangular, and the grille 14 arranged on it is in the shape of a vertical line, forming a longitudinal parallel pipeline, and a laterally arranged diversion channel cavity 19 is formed at the lower end of the grille 14 to connect with the water inlet 10, On the upper end of the grille 14, there is a horizontally arranged confluence channel cavity 18 connected to the water outlet 11; the longitudinal linear grille 14 arranged on the rectangular waterway plate 2 is provided with a transverse diverter at the lower end of the grille 14. The upper and lower height of the waterway cavity 19 (that is, the distance from the water inlet to the bottom of the grid) is 60 mm, and the upper and lower height of the horizontal confluence waterway cavity 18 (that is, the distance from the water outlet to the top of the grid) is set at the upper end of the grid 14 is 8 mm; The vertical linear grid 14, wherein the width of each w...

Embodiment 3

[0023] The water channel plate 2 described in this embodiment is rectangular, its lower area is a cavity, and its upper area is provided with a grid 14. The grid 14 is S-shaped to form a series of water channel cavities 9, and its cross section is rectangular or trapezoidal. The section width is 6.6mm, the height is 2.7mm, the cavity length of the lower area of the water channel plate 2 is 64mm; the electrothermal film heating plate 1 is curved, so that it forms a local Gap, the electrothermal film heating plate 1 and the grid (14) have partial contact around the waterway plate, the length of the close contact between the electrothermal film heating plate 1 and the grid 14 is 3% of the total length of the grid 14, and the remaining 97% of the length is matched as Clearance fit, the best clearance is 0.5-0.8mm; the thermistor 7 is set on the electrothermal film heating plate 1, the distance between the center of the thermistor 7 and the water outlet 11 is 20mm, and the distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Section width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com