Wireless communication small card embedding device and manufacturing method thereof

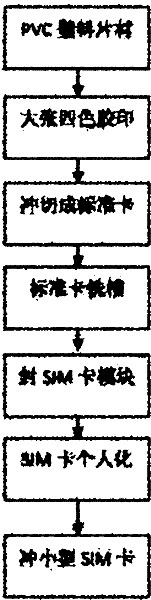

A small card and embedded device technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of capital investment barriers, inability to greatly improve material utilization, and inability to use IC cards, etc., to achieve satisfactory efficiency and low processing costs Low cost and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

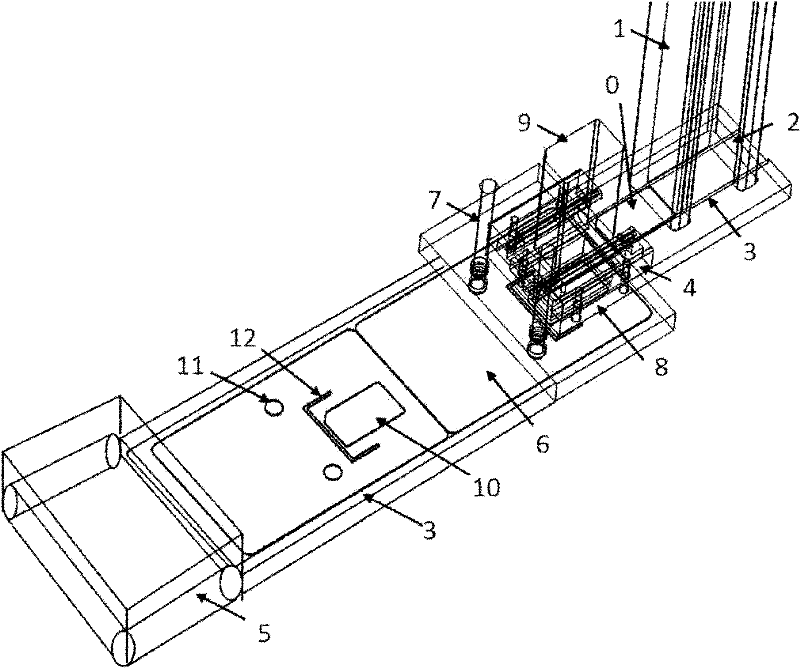

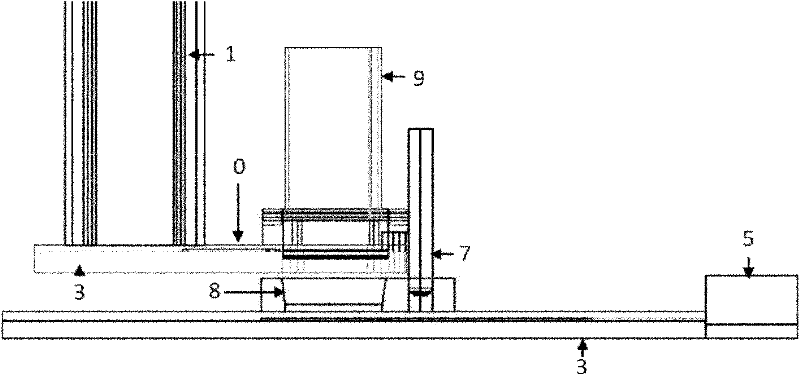

[0033] like figure 1 and figure 2 As shown, the wireless communication small card embedding device involved in this embodiment includes: small card stacking mechanism 1, unloading mechanism 2, transmission mechanism 3, embedding mechanism 4, material receiving mechanism 5 and card tray 6, wherein: small card The stacking mechanism 1, the embedding mechanism 4 and the receiving mechanism 5 are sequentially connected in series. The unloading mechanism 2 is located at the lower part of the small card stacking mechanism 1 and is connected with the small card stacking mechanism 1. The transmission mechanism 3 is connected with the unloading mechanism 2 respectively. , the embedding mechanism 4 is connected with the receiving mechanism 5, the card tray 6 is located at the junction of the transmission mechanism 3 and the embedding mechanism 4 and is used to embed the miniaturized SIM card 0, and the card tray embedded in the miniaturized SIM card 0 passes through the transmission me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com