Ceramic heater

A ceramic heater, ceramic technology, applied in ohmic resistance heating, heating element material, heating element shape and other directions, can solve problems such as damage, large thermal stress, etc., and achieve improved durability, increased high temperature strength, and effective anchoring effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

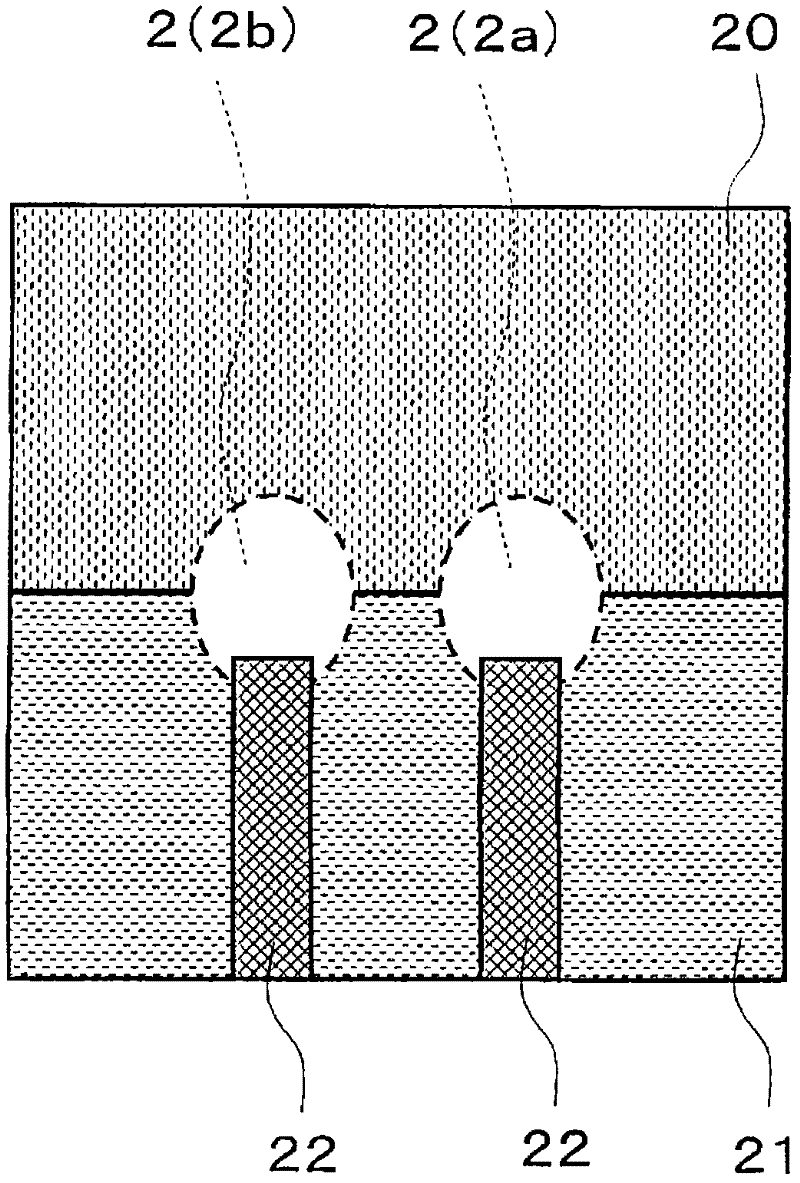

[0018] Hereinafter, examples of embodiments of the ceramic heater of the present invention will be described in detail with reference to the drawings.

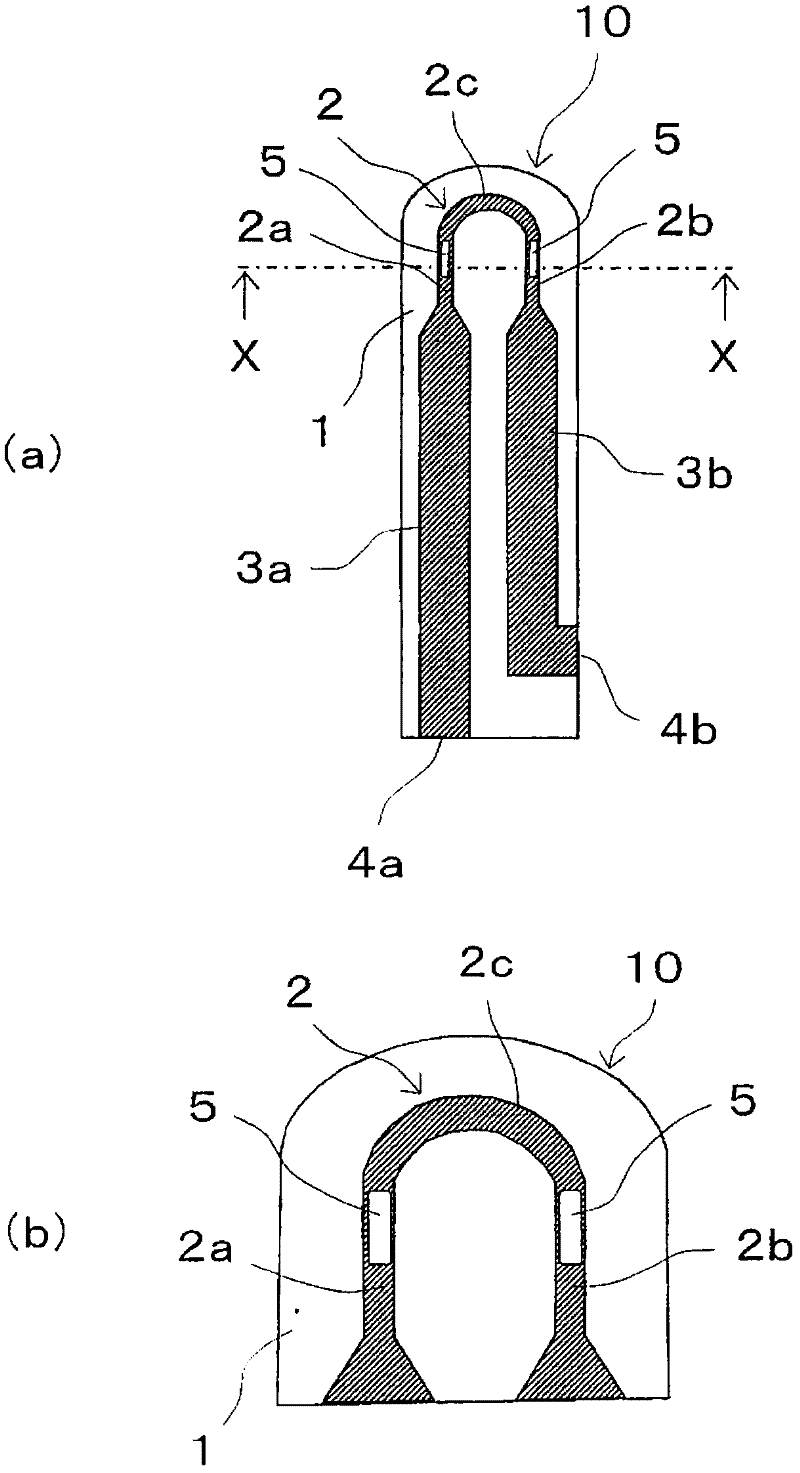

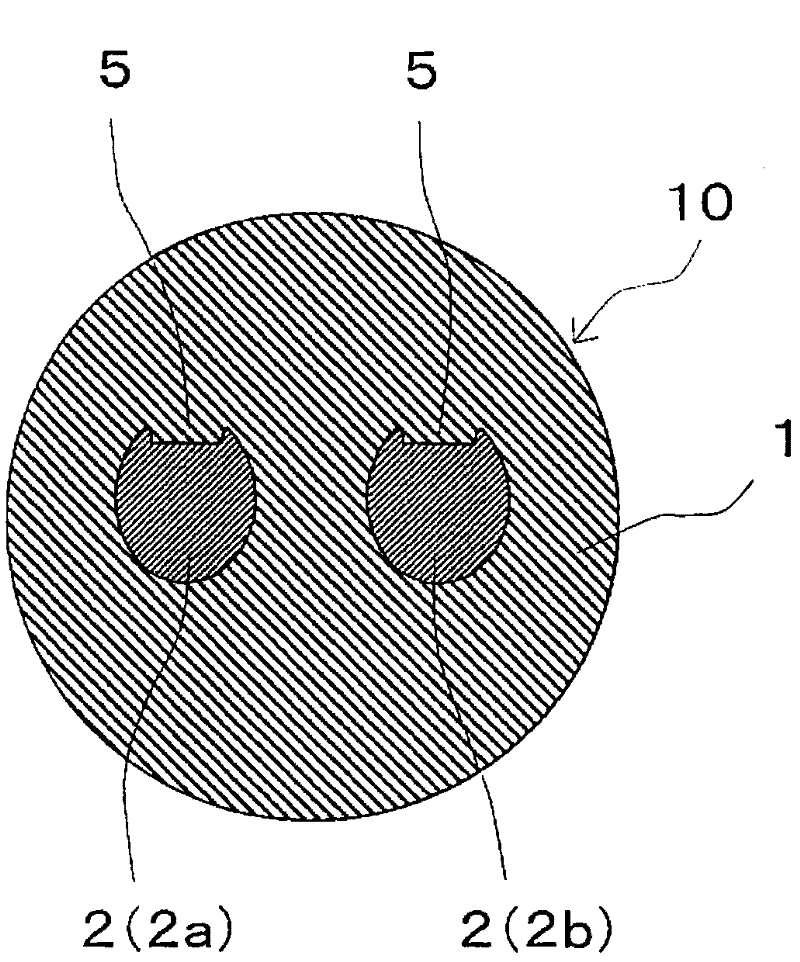

[0019] figure 1 (a) is a perspective internal plan view showing an example of an embodiment of the ceramic heater of the present invention, figure 1 (b) is an enlarged view of its main part. exist figure 1 In , the transparent heating element 2 is shown with hatching. in addition, figure 2 yes figure 1 X-X line sectional view of the example shown.

[0020] The ceramic heater 10 of this example has: a base body 1, which is made of ceramics; The connection part 2c of the set part 2a, 2b; The heating element 2 has a U-shape composed of two opposing portions 2a, 2b arranged in parallel in the base body 1, and an arc-shaped connection portion 2c connecting the opposing portions 2a, 2b. The electric current flows to the heating element 2 through the lead-out parts 3a and 3b, thereby causing the heating element 2 to generate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com