Method for comprehensive recycling of crude terephthalic acid (CTA) residue

A technology of resource utilization and residue, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of inconvenient operation, large investment, energy consumption, etc., and achieve high economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

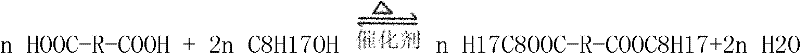

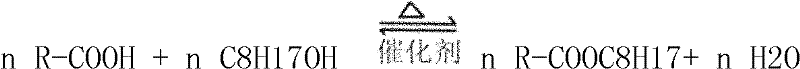

[0038] The first step is to prepare mixed organic isooctyl ester from CTA residue

[0039] Put 4kg of CTA residue, catalyst and 9.1kg of isooctyl alcohol into the reaction kettle and raise the temperature to 225℃, keep the reaction temperature, reflux for about 10 hours, measure the acid value until the acid value ≤0.5mg koh / g, stop the reaction, and produce the crude The ester enters the next process.

[0040] The second step of dealcoholization

[0041] The isooctyl alcohol in the crude ester is recovered and used in the next batch of production. The recovery is divided into three processes: normal pressure dealcoholization, vacuum dealcoholization and steam stripping dealcoholization. Atmospheric dealcoholization means that the alcohol in the crude ester is steamed out under normal pressure. Vacuum dealcoholization refers to the distillation and dealcoholization under vacuum. The steam stripping dealcoholization is based on the principle of partial pressure. The trace amount of ...

Embodiment 2

[0054] It is basically the same as Example 1, except that in the first step: Put 4kg of CTA residue, catalyst and 9.45kg of isooctanol into the reactor and raise the temperature to 240°C, keep it for reaction, reflux for about 8 hours, and measure the acid Until the acid value is less than or equal to 0.5 mg koh / g, the reaction is terminated, and the crude ester produced enters the next step.

Embodiment 3

[0056] It is basically the same as Example 1, except that in the first step: Put 4kg of CTA residue, catalyst and 9.8kg of isooctyl alcohol into the reaction kettle and raise the temperature to 220°C, keep the temperature for reaction, reflux for about 12 hours, and measure the acid Until the acid value is less than or equal to 0.5 mg koh / g, the reaction is terminated, and the crude ester produced enters the next step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com