High-temperature hot dipping method for producing steel strip hot dipped with zinc-base alloy

A technology of hot-dip galvanizing and steel strip, which is applied in hot-dip galvanizing process, metal material coating process, coating and other directions to achieve the effect of improving operating power, saving zinc resources and reducing the amount of coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

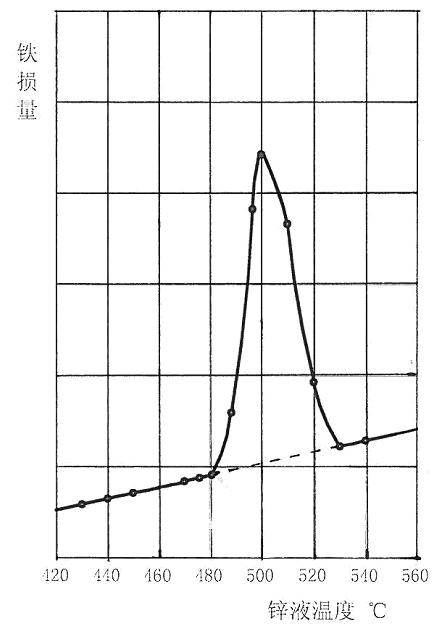

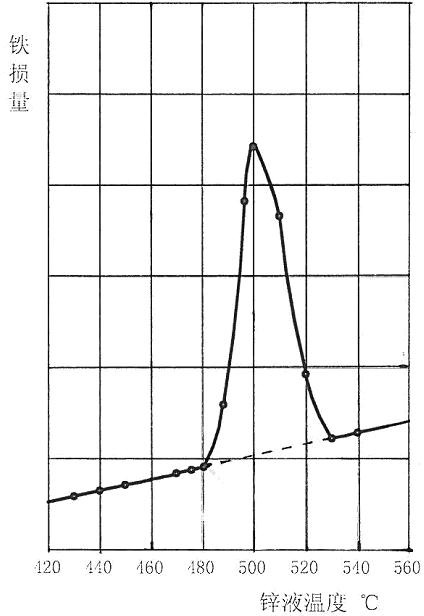

Image

Examples

Embodiment 1

[0042] Example 1: In the production of five-element zinc alloy (zinc-aluminum-magnesium-silicon rare earth) hot-dip steel strip, the temperature of the plating solution is controlled at 535±5°C; the operating power of the air knife blower is adjusted to a power that does not cause metal flow marks on the plate surface The highest value in the range.

Embodiment 2

[0043] Example 2: In the production of five-element zinc alloy hot-dip steel strip, the temperature of the plating solution is controlled at 545±5°C; the operating power of the air knife blower is adjusted to the highest value in the power range that does not cause metal flow marks on the plate surface.

Embodiment 3

[0044] Example 3: In the production of five-element zinc alloy hot-dip steel strip, the temperature of the plating solution is controlled at 555±5°C; the operating power of the air knife blower is adjusted to the highest value in the power range that does not cause metal flow marks on the plate surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com