Method for operating a handheld work apparatus having a combustion engine

一种工作器械、内燃机的技术,应用在手持式工作器械领域,能够解决离合器损坏、内燃机转速下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

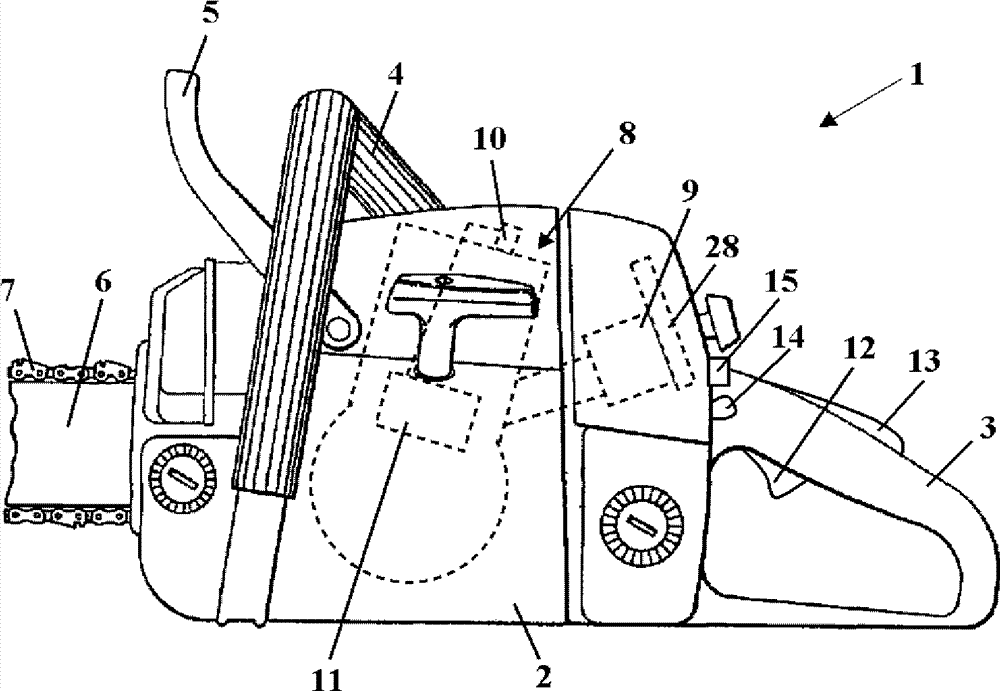

[0028] figure 1 A power saw 1 is shown schematically as an example for a hand-held power tool. However, the invention can also be provided in other hand-held working implements (for example cutters, rock cutters, hedge shears, etc.). The power saw 1 has a housing 2 , a rear handle 3 and a grip tube 4 . A guide rail 6 is fastened to the housing 2 , on which a saw chain 7 is arranged circumferentially. Arranged on the side of the grip tube 4 facing the guide rail 6 is a hand guard 5 which at the same time can be used to activate a chain brake (not shown).

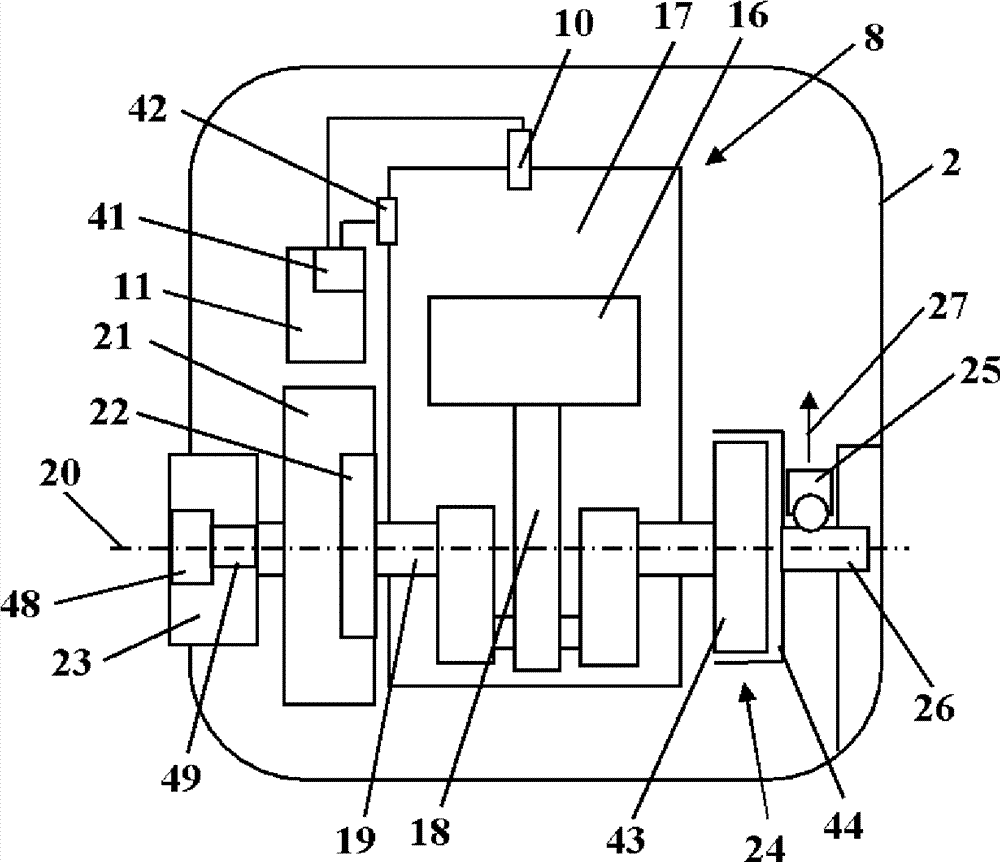

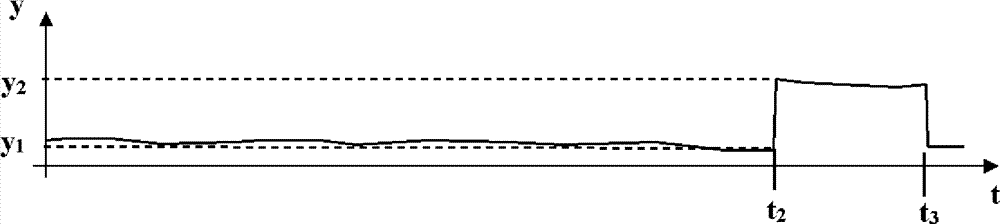

[0029] An internal combustion engine 8 arranged in the housing 2 serves to drive the saw chain 7 . The internal combustion engine 8 is a single-cylinder engine, advantageously a mixed-lubrication engine, such as a two-stroke engine or a mixed-lubrication four-stroke engine. The internal combustion engine 8 draws in combustion air via an air filter 28 and a carburetor 9 . Instead of the carburetor 9 , a fuel valve can als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com