Air heater for cold spray

An air heater and cold spraying technology, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat utilization efficiency, large insulation part volume, high protection requirements, etc., and achieve novel structure and construction Good environment and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

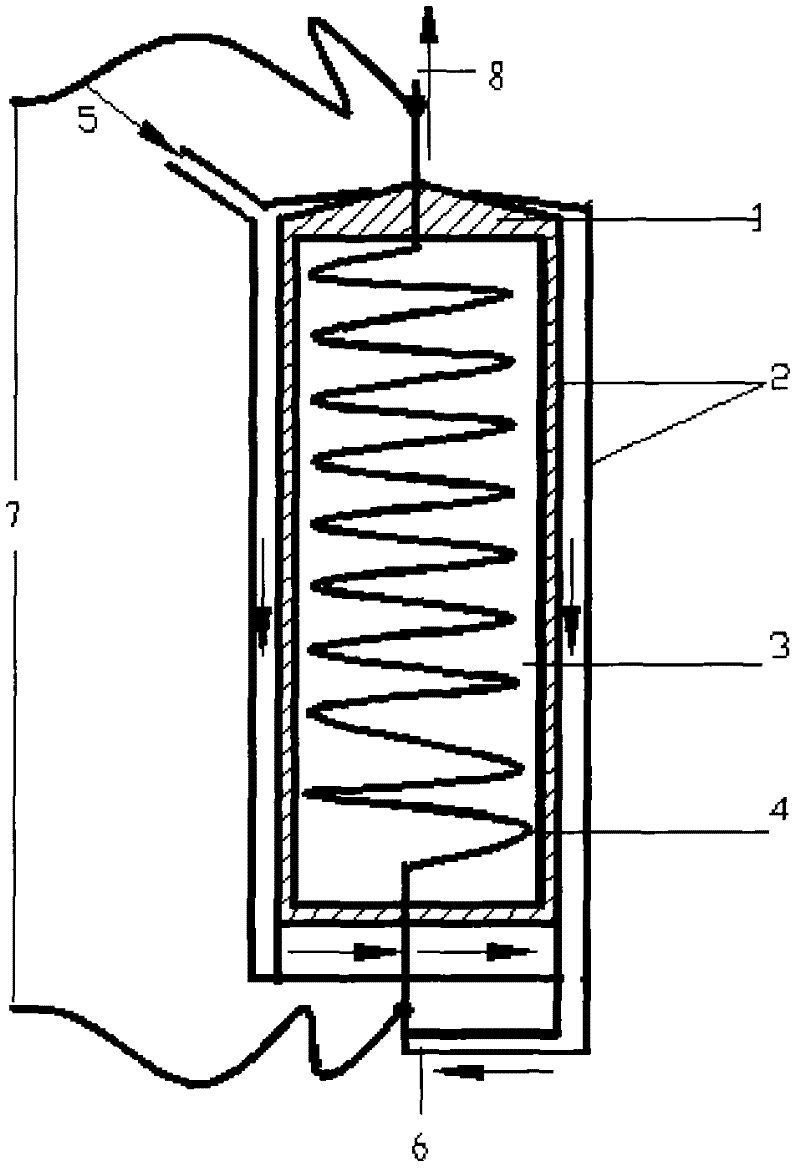

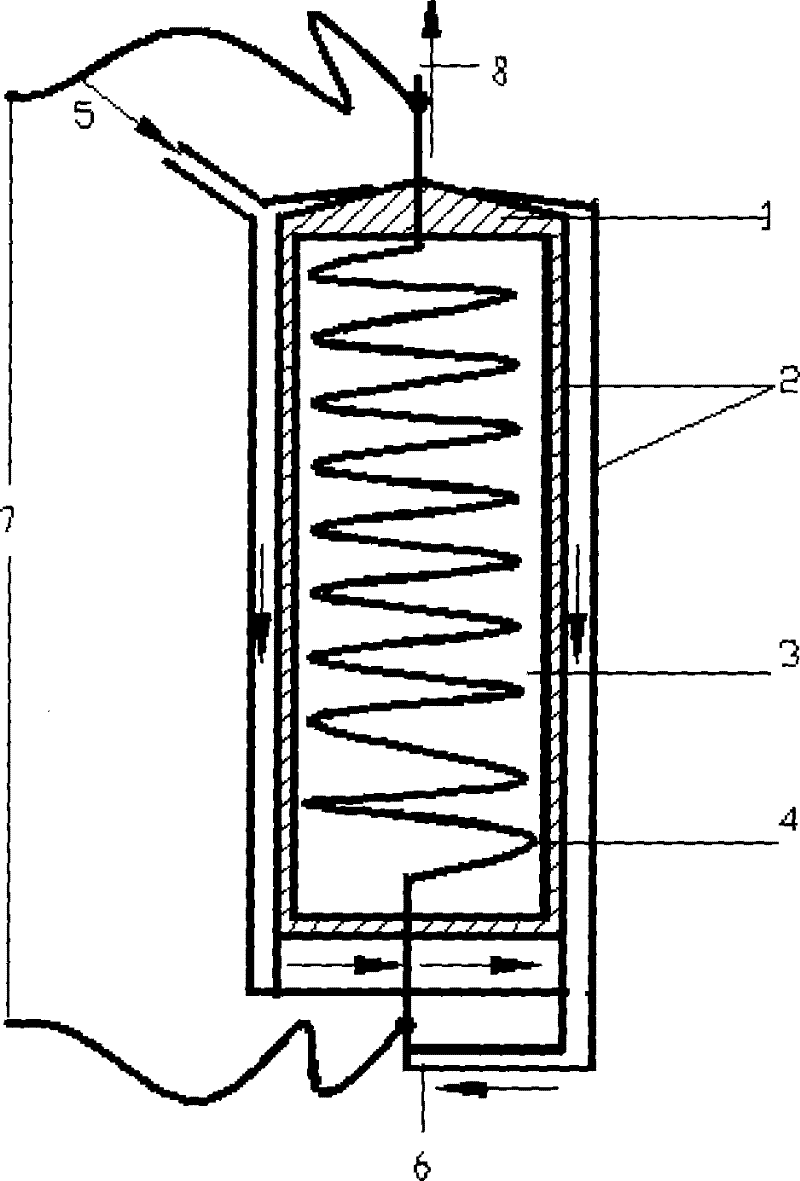

[0011] The main structure of this embodiment includes insulation brick 1, metal shell tube 2, ceramic fiber insulation layer 3, heating element 4, cold gas inlet 5, heating gas connection pipe 6, heating power connection 7 and hot gas outlet 8, cylindrical The top corner of the metal shell tube 2 is equipped with an oblique cold gas inlet 5, and the bottom corner of the metal shell tube 2 is equipped with an extended heating gas connection pipe 6 or a metal hose structure; the inner wall of the metal shell tube 2 is of equal thickness. In the parallel structure, there are arranged and distributed thermal insulation bricks 1. In the cavity formed in the inner side wall of the thermal insulation brick 1, there is a hollow pipe-type spiral heating element 4 vertically formed. The outer sides of the two ends of the heating element 4 are respectively connected to the power supply wiring 7. The external structure of the hollow-pipe heating element 4 is a spiral hollow structure. The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com