Horizontal gas separation device

A gas and horizontal technology, applied in the field of horizontal gas partition devices, can solve the problems of low safety performance, friction of sealing surfaces, complicated operation, etc., and achieve the effects of prolonging service life, good sealing performance and ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

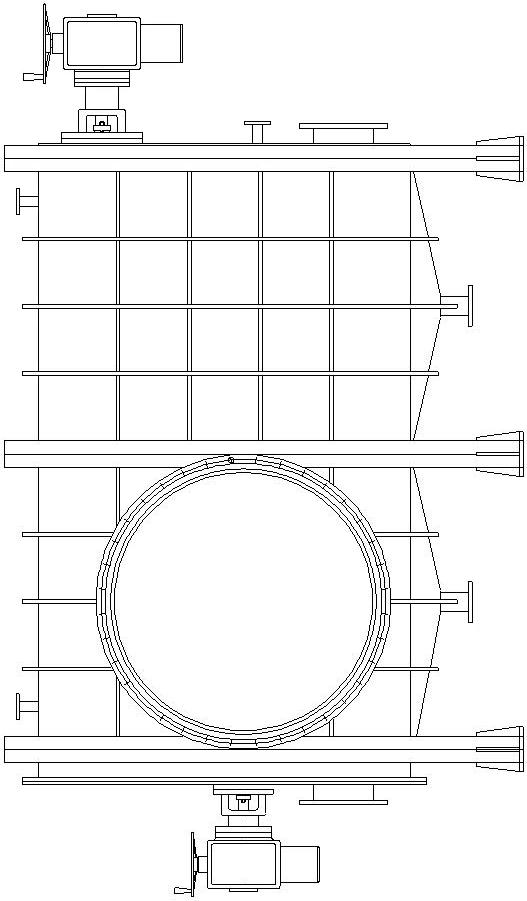

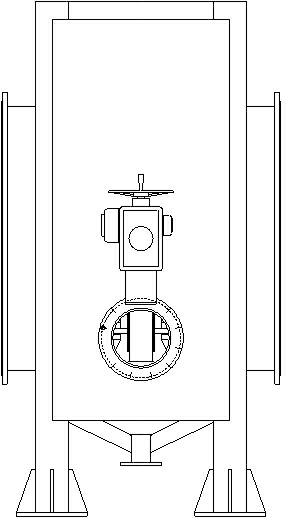

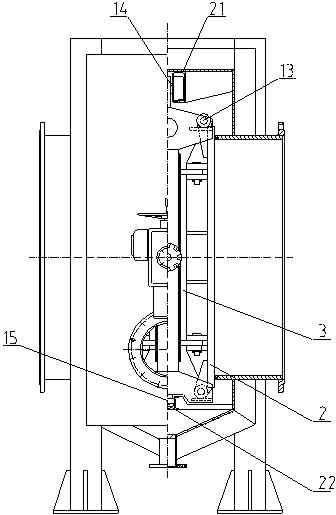

[0018] see figure 1 , figure 2 as well as image 3 and Figure 4 As shown, the present invention includes: a valve body 1, which is respectively provided with an inlet and an outlet, and the inlet and outlet are respectively used for connecting pipelines for conveying medium. A valve rod 10 is arranged in the valve body, and the valve rod is connected to the central support of the valve core. The spool center support includes: a support body 3, the upper part of which is connected to the valve stem nut 9, the valve stem nut is threadedly connected to the valve stem, and the support body is a frame for connecting the valve stem and the gate. The valve stem adopts multi-thread threads, that is, the valve stem is a double-headed trapezoidal screw, which makes the opening and closing of the center support frame of the valve core quick and the number of turns of the valve stem is small. The sealing surface provided on the inlet and outlet valve bodies is a layer of stainless s...

Embodiment 2

[0026] The invention comprises: a valve body, an inlet and an outlet are arranged on the valve body, and the inlet and the outlet are respectively used for connecting pipelines for conveying medium. A valve rod is arranged in the valve body, and the valve rod is movably connected with the center bracket of the valve core. The spool center support includes: a support body 3, the upper part of the support body is connected to the valve stem nut 9, and the valve stem nut is threadedly connected to the valve stem. The center support of the spool moves horizontally under the drive of the valve stem. The support body of the spool center bracket is provided with a strut, the strut is threadedly connected with a strut slider, the strut slider is hinged with a connecting rod, and one end of the strut is connected with a half coupling, corresponding to the position of the strut. The valve body is provided with a strut shaft, and one end of the strut shaft is connected with another half...

Embodiment 3

[0032] The invention comprises: a valve body, on which an inlet and an outlet are arranged, and a valve rod is arranged in the valve body, and the valve rod is movably connected with the center bracket of the valve core. The spool center support includes: a support body 3, the upper part of the support body is connected to the valve stem nut 9, and the valve stem nut is threadedly connected to the valve stem. The center support of the spool moves horizontally under the drive of the valve stem. There is a strut on the central support of the valve core, a strut slider is set on the strut, a connecting rod is hinged on the strut slider, one end of the strut is connected with a half coupling, and a valve body corresponding to the position of the strut is provided with There is a pole shaft, and one end of the pole shaft is connected to another half coupling, and the half coupling connected to the pole and the half coupling connected to the pole shaft form a complete jaw coupling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com