Automatic temperature control gas cooker and temperature control method

A technology for gas stoves and cooktops, which is applied in the field of gas stoves, can solve the problems of transmission, easy failure, poor thermal conductivity, etc., and achieves the effects of accurate measurement and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

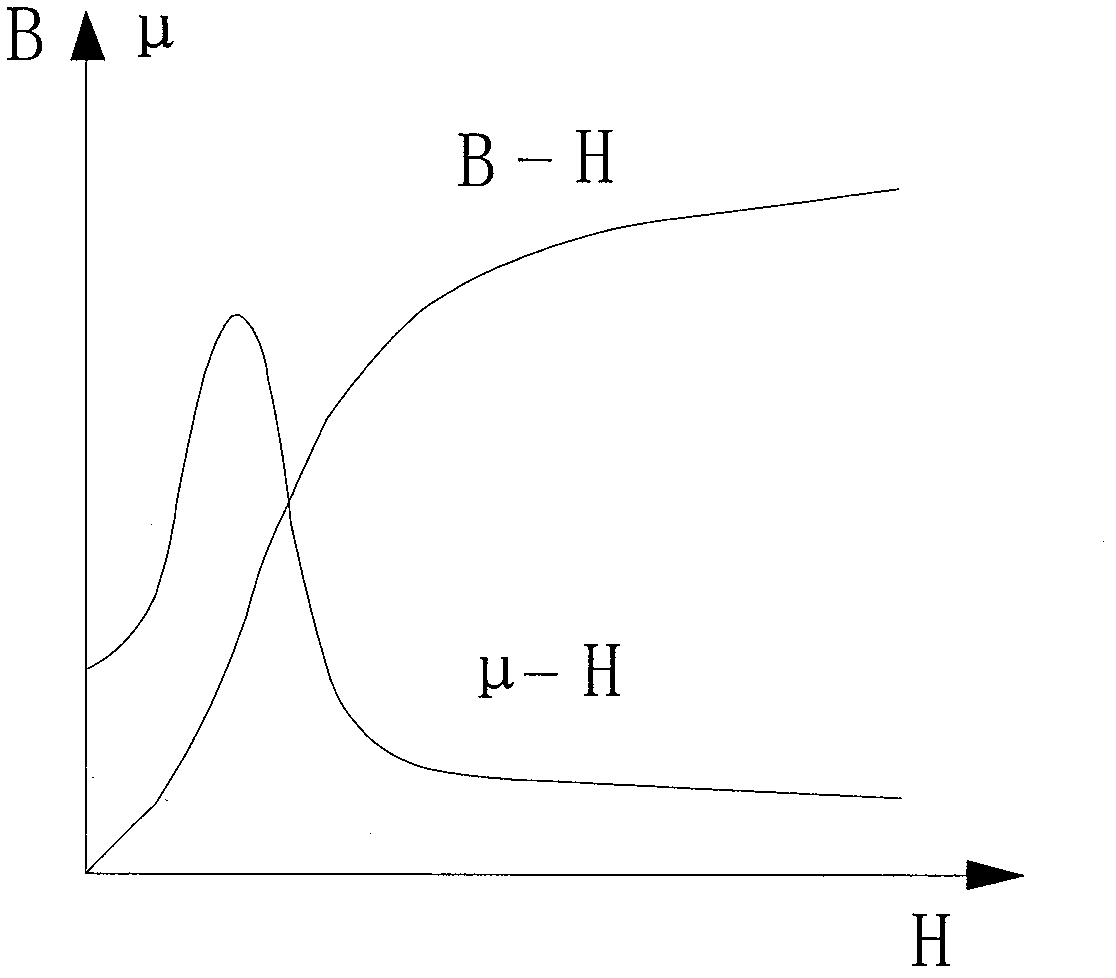

[0039] The invention utilizes the magnetic permeability temperature characteristic of the iron or ferrimagnet to realize the non-contact temperature measurement method of the gas cooker. The magnetic permeability (or magnetic induction, magnetization) of ferromagnets, ferrimagnets or ferrites has a very complicated relationship with temperature and other parameters. They are affected by factors such as frequency, temperature, and magnetic property transformation before and after the Curie point. For details, please refer to the disclosure content cited below.

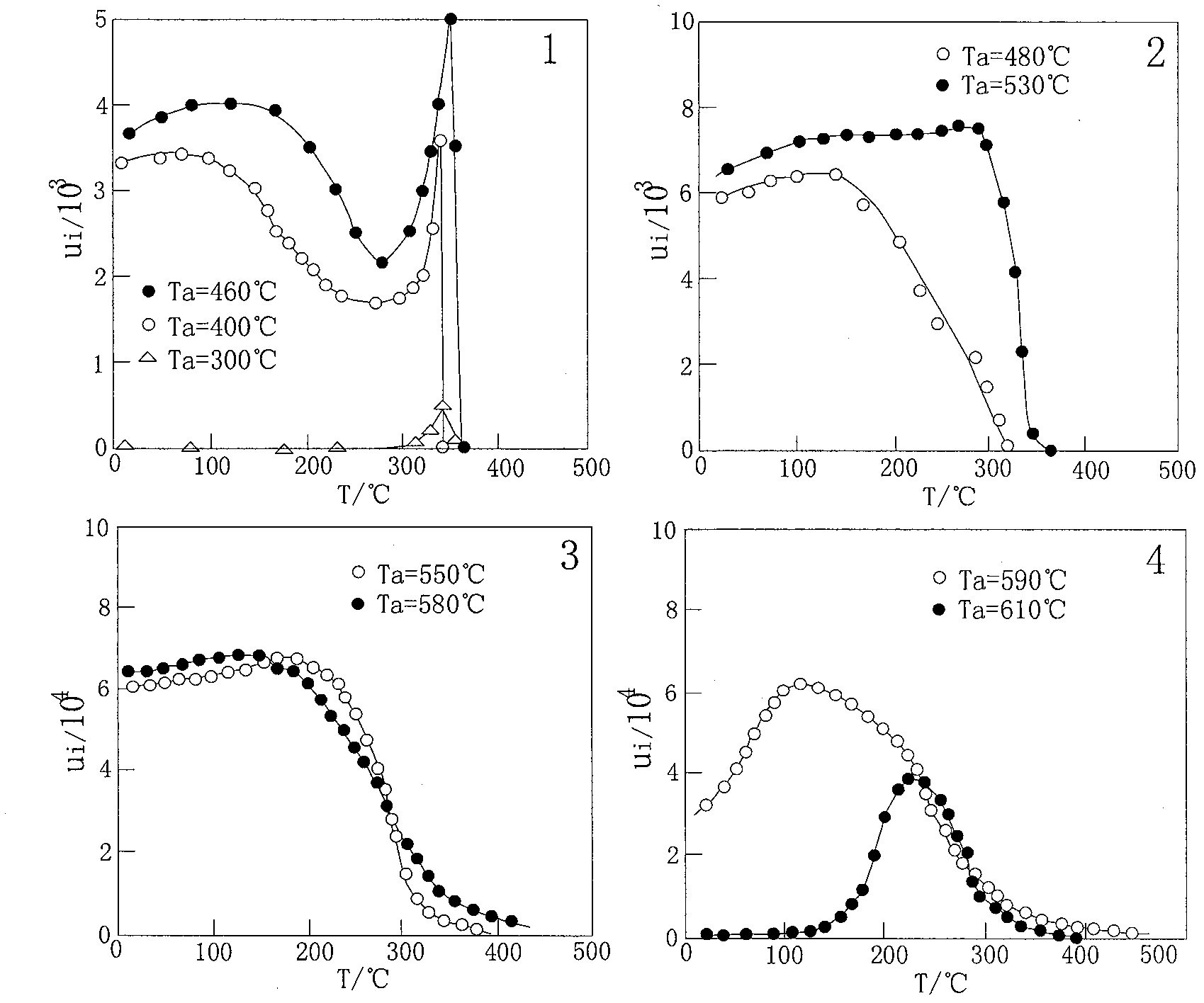

[0040] "Functional Materials" Supplement 2001 No. 10 published a "Fe 83 Nb 6 B 11 Alloy Magnetic Permeability Changes with Temperature", from which it can be seen that the alloy magnetic permeability has a complex relationship with temperature, and even, under different conditions, their relationship coefficients have completely different trends , see attached figure 1 .

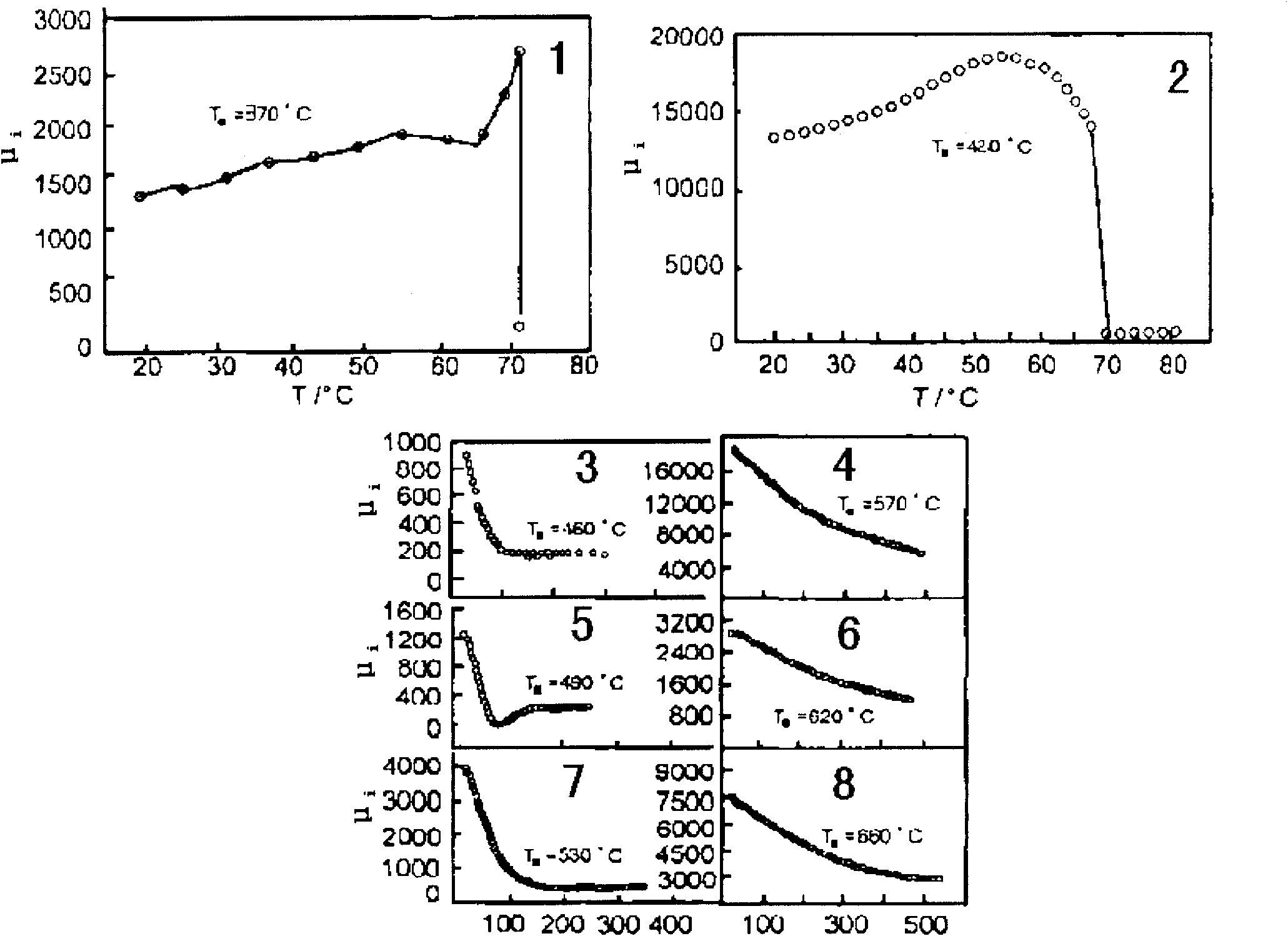

[0041] "Relationship between magnetic perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com