Liposome composite phospholipid capable of adjusting phase-transition temperature and application thereof

A technology of compound phospholipid and phase transition temperature, which is applied in the directions of liposome delivery, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. limited problems, to achieve the effect of enhanced stability, reduced leakage, and good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of Calcein Complex Phospholipid Liposome and Test of Release Behavior in Vitro

[0038] According to the molar ratio of DPPC and HSPC of 2:8, 4:6, 5:5, 6:4 and 8:2, weigh 120 mg each of the composite phospholipid materials, dissolve them in 10 mL chloroform, and place them in 50 mL eggplant-shaped bottles for 60 °C to form a thin film by rotary evaporation under reduced pressure, take out the eggplant-shaped bottle, and place it in a vacuum oven at 55 °C for 12 hours. Then, 5 mL of pH 7.4 phosphate buffered saline (PBS) containing 90 mM calcein was added to the eggplant-shaped flasks, and hydrated by rotation at 60 °C for 40 min. , 50 times) to obtain calcein complex phospholipid liposomes with different molar ratios of DPPC and HSPC. Calcein DPPC and HSPC liposomes containing only one phospholipid material of DPPC and HSPC were prepared respectively in the same way.

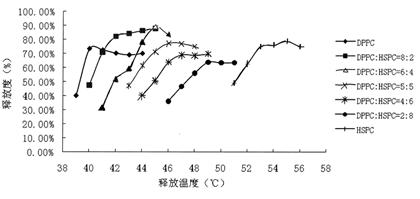

[0039] Remove the free drug from the above calcein liposomes by gel column chr...

Embodiment 2

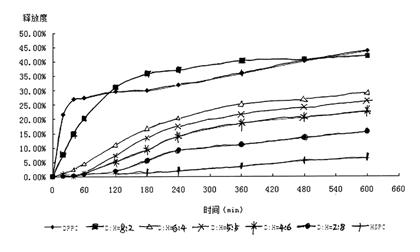

[0041] Example 2 Comparison of release behavior of calcein liposomes with different phospholipid compositions at 37°C

[0042] Get the DPPC that embodiment 1 prepares and HSPC mol ratio is the calcein liposome that 2:8, 4:6, 5:5, 6:4 and 8:2 composite phospholipid and single DPPC and HSPC material make, then The release behavior of the above calcein liposomes was compared at 37°C. For specific experimental results, see figure 2 shown. The experimental results show that after adding a certain proportion of HSPC, the stability of the prepared calcein complex phospholipid liposomes at 37 ° C is significantly better than that of single DPPC phospholipid calcein liposomes, and there is an obvious correlation, the ratio of HSPC The higher the value, the more stable the complex phospholipid liposome and the lower the release rate. Therefore this experiment further shows that the liposome that the preferred DPPC of the present invention and HSPC composite phospholipid material are ...

Embodiment 3

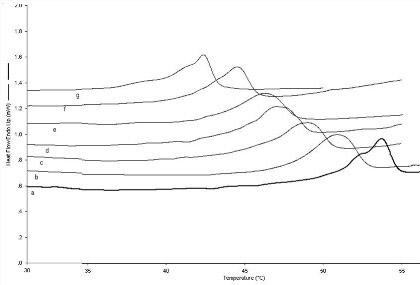

[0043] Example 3 Differential Scanning Calorimetry (DSC) Determination of the Correlation Between the Phase Transition Temperature of Liposomes and the Composition of Phospholipids

[0044] 1. Preparation of liposomes: Weigh 120 mg of composite phospholipid materials (the molar ratios of DPPC and HSPC are 2:8, 4:6, 5:5, 6:4, 8:2) and dissolve in 10 mL respectively Chloroform, then placed in a 50 mL eggplant-shaped bottle, 60 ℃ reduced pressure rotary evaporation to form a thin film, take out the eggplant-shaped bottle, and place it in a vacuum drying oven at 55 ℃ for 12h. Add 5 mL of pH 7.4 phosphate buffered saline (PBS) into the eggplant-shaped bottle, and hydrate with rotation at 60 °C for 40 min. Composite phospholipid liposomes made of molar ratios of DPPC and HSPC (2:8, 4:6, 5:5, 6:4, 8:2, respectively).

[0045] DPPC and HSPC liposomes containing only phospholipid materials of DPPC and HSPC were prepared respectively by the same method.

[0046] Get the composite phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com