Composite steel plate

A technology of clad steel plates and steel plates, applied in building components, buildings, building structures, etc., can solve problems such as harming the environment, black smoke, endangering the lives of users, etc., and achieve the effect of improving safety and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

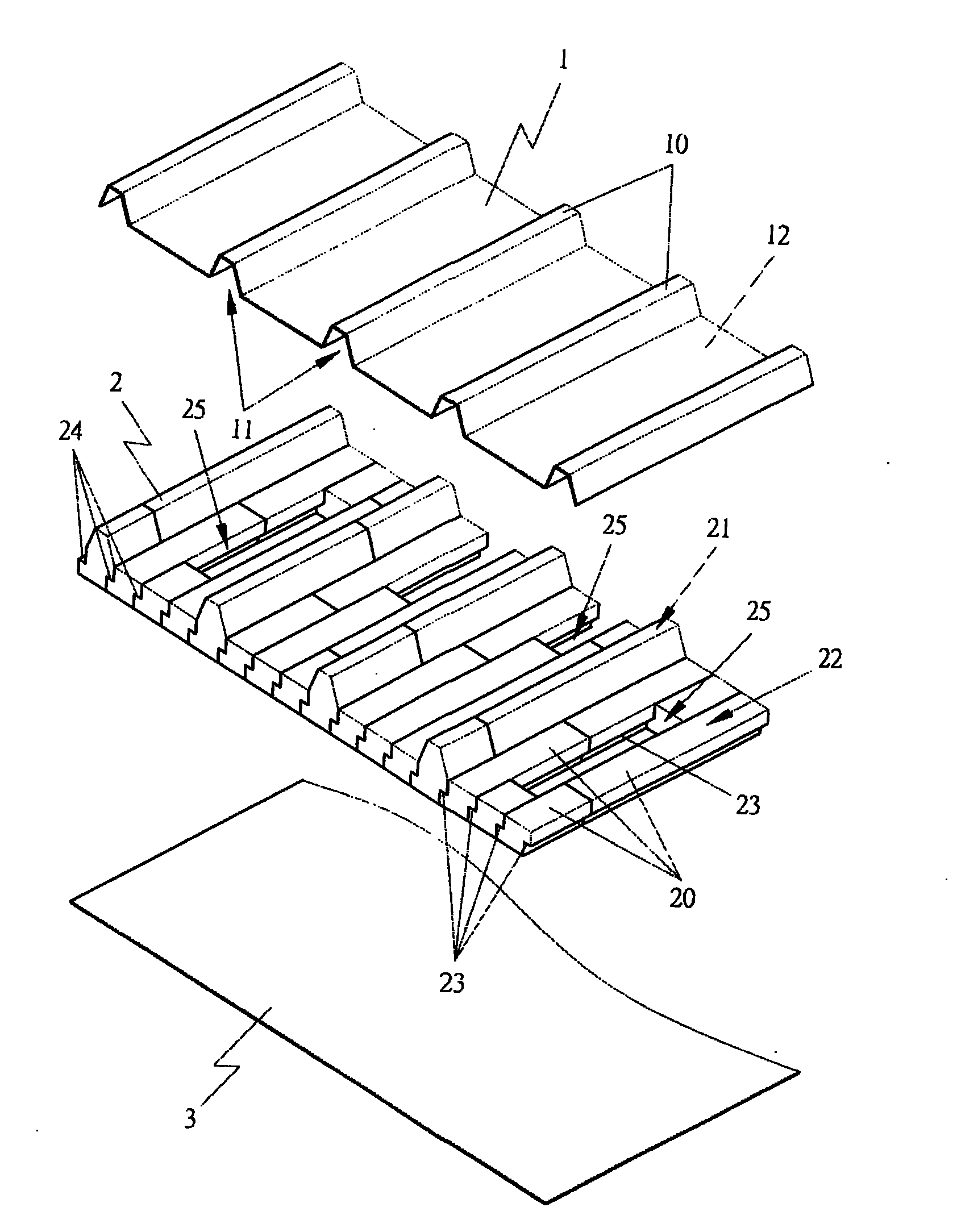

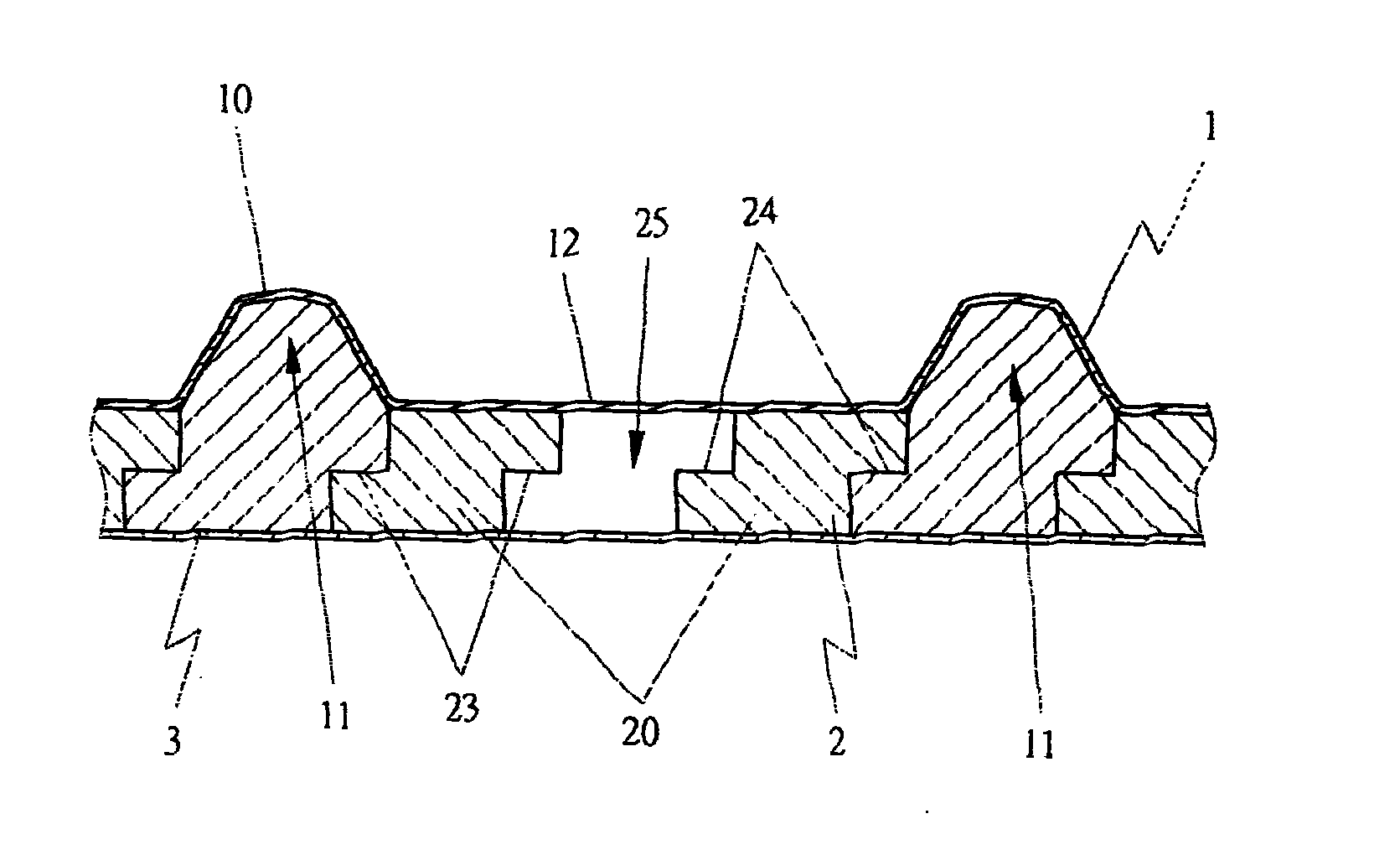

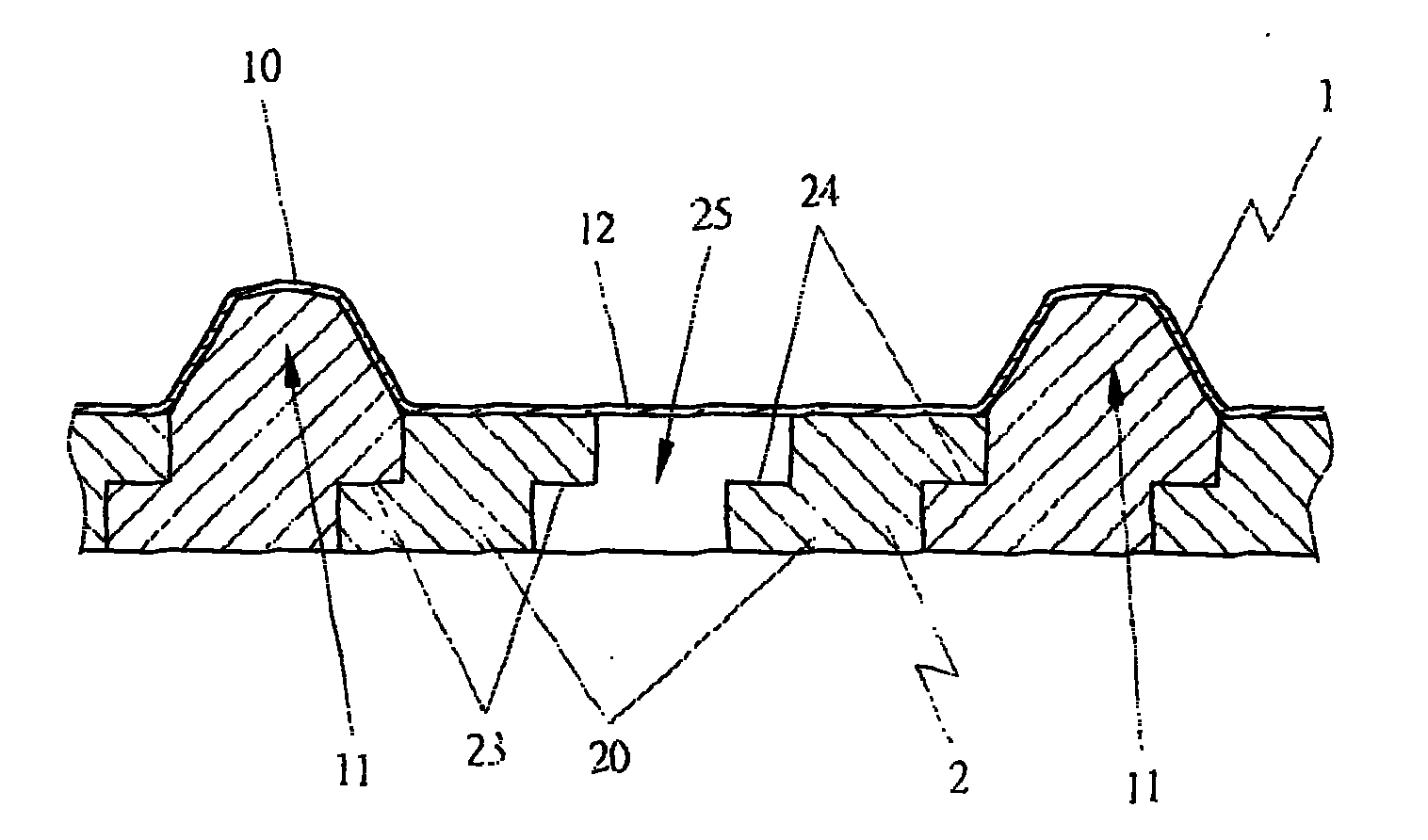

[0037] In this way, in order to enable your examiner to fully understand the present invention, the accompanying drawings are hereby explained as follows:

[0038] Such as figure 1 and 2 Shown, be embodiment (one) of the present invention, present embodiment (one), comprise:

[0039] The upper plate 1 is made of a steel plate, and the steel plate can be provided with one or more peaks 10 . On the other hand, a groove 11 is formed inside the peaks 10 , and the steel plate is also provided with one or more flat surfaces 12 .

[0040] The interlayer 2 is made of glass foam or foamed glass, which has the advantage of being recyclable after use. The interlayer 2 is composed of a plurality of units 20. The interlayer can also cooperate with the groove 11 and the groove of the aforementioned upper plate 1. The plane 12 is provided with a peak 21 and a plane 22 . And when the interlayer 2 is composed of a plurality of units 20, a plurality of hollow grooves 25 must be formed, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com