Special-grade fireproof highly-anti-flaming nanometer power cable

A power cable, high flame retardant technology, applied in the field of power cables, can solve the problems of poor flame retardancy of ordinary plastic insulated cables, harm to the environment, equipment and personnel life, and reduced electrical insulation, achieving a bright market prospect and small line loss. , The effect of using high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

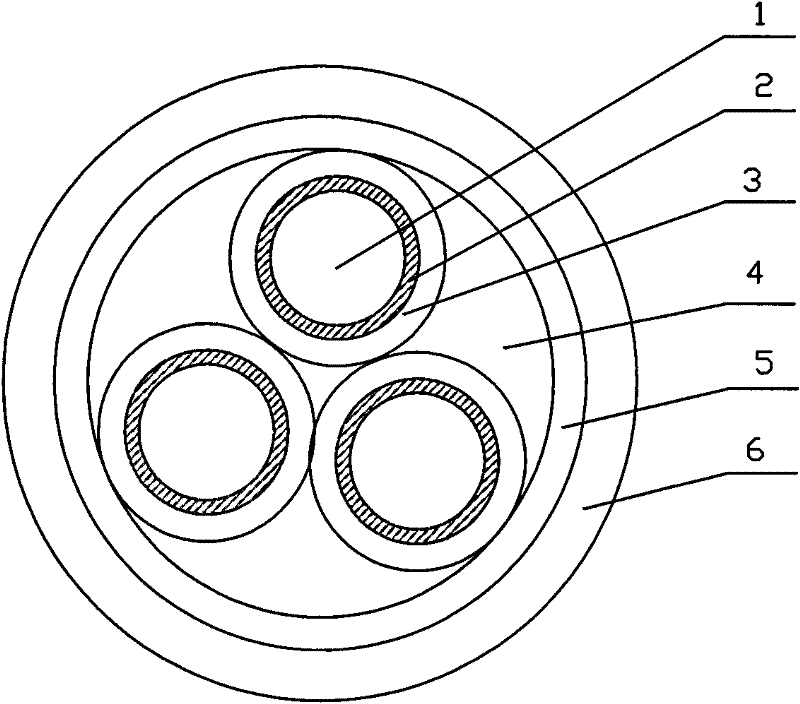

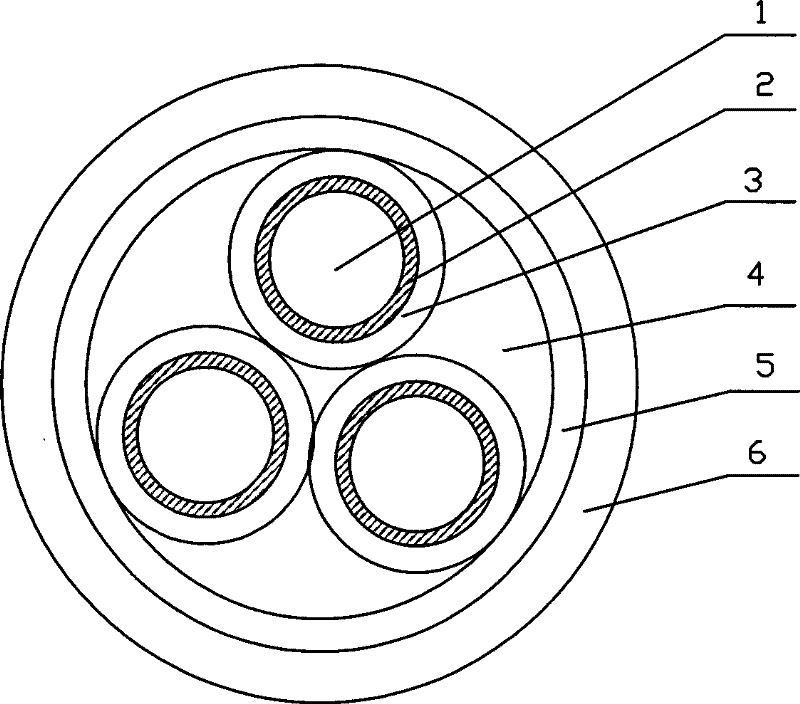

[0009] A nano super fire-resistant high-flame-retardant power cable, including several wire cores and outer sheaths 6, the wire cores are composed of a copper conductor 1, a double-layer fire-resistant mica tape 2 wrapped around the copper conductor 1, and a nano-fireproof insulating layer 3 Composition, the core is filled with a flame-retardant filling rope 4, and wrapped with a glass fiber tape 5, and the nano-fireproof outer sheath 6 is extruded and wrapped outside the glass fiber tape 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com