Molten drop furnace for measuring molten drop point of iron ore

A technology of melting drop point and iron ore, which is applied in the direction of furnace, furnace type, investigation stage/state change, etc., can solve the problems of inaccurate measurement of melting drop point and material temperature, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

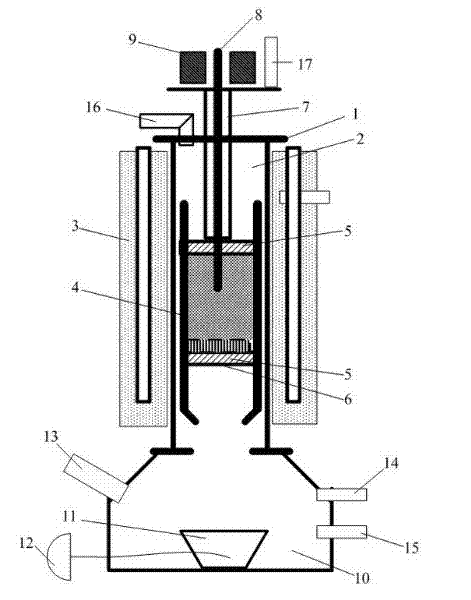

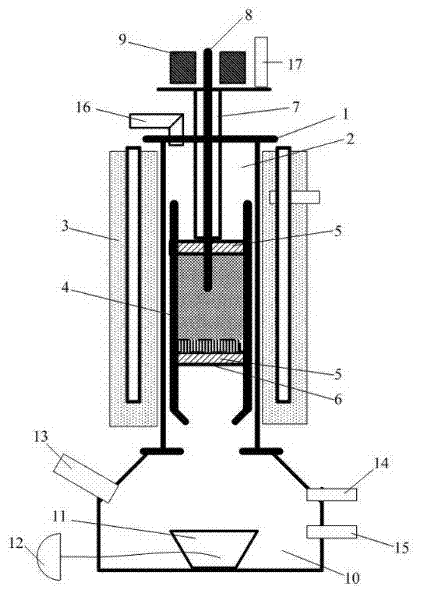

[0020] As shown in the figure, the dropping furnace for measuring the dropping point of iron ore of the present invention includes a furnace body 1 and a control device. The high temperature resistant furnace body 1 is made of high temperature resistant materials, such as corundum, etc. A closed hearth 2, outside the hearth 2, is provided with a heating device 3, and the heating device 3 heats the hearth 2 and the materials in it under the control of the control device of the droplet furnace to reach the heating temperature and temperature rise required by the process. Parameters such as speed, the heating device 3 can be heated by electric heating, and an electric heating rod is arranged therein; a graphite crucible 4 is provided in the furnace 2, and the heating device 3 heats the furnace 2, the graphite crucible 4 and the graphite crucible 4 under the control of the control device. ore samples. When charging, the ore sample is loaded into the graphite crucible 4, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com