Encapsulating bracket structure for high-reliability luminous device

A technology for light-emitting devices and packaging brackets, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the operating temperature of light-emitting diode chips, reducing the reliability of light-emitting diodes, poor solderability, etc. Reliability, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

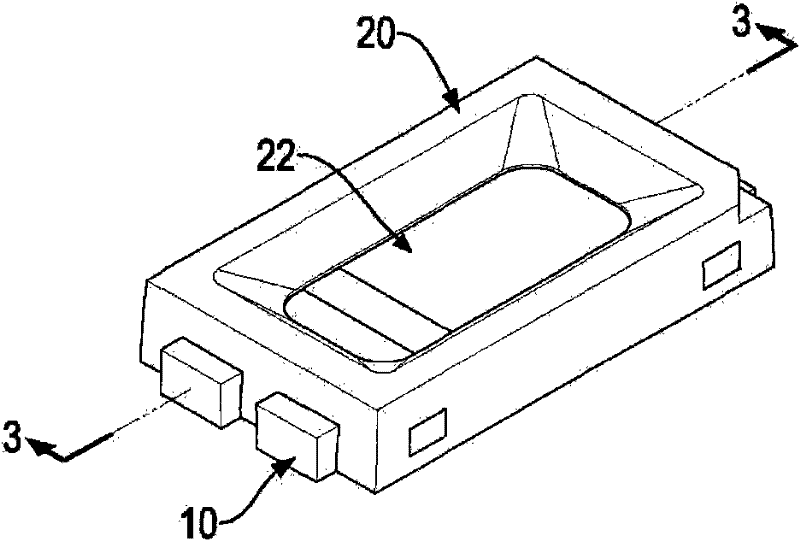

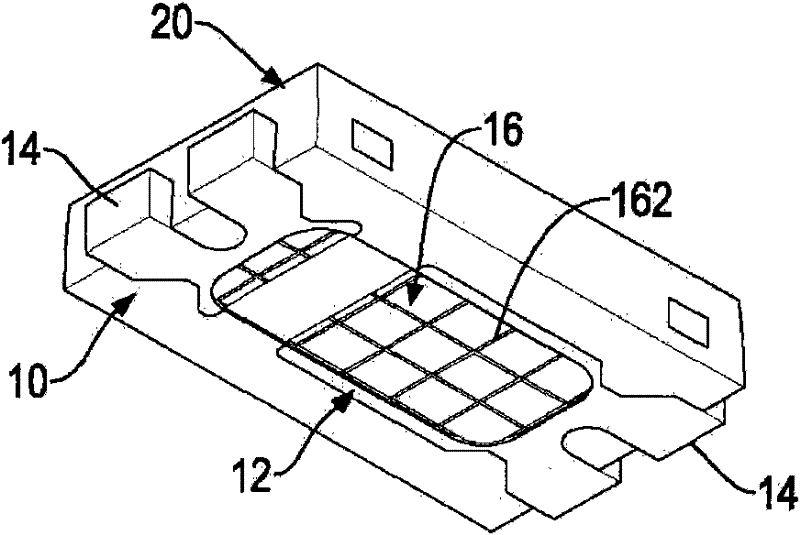

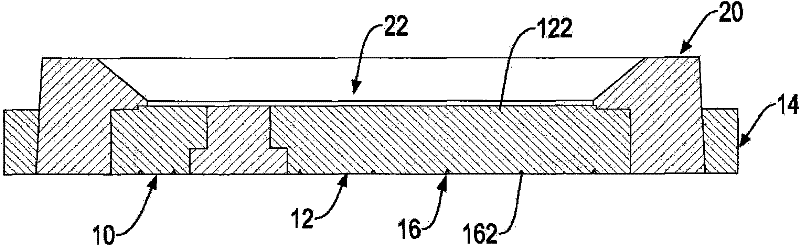

[0031] The present invention provides a high-reliability packaging support structure for light-emitting devices, please refer to Figures 1 to 3 , it can be seen from the figure that the light-emitting device packaging bracket structure of the present invention includes a bracket (10) and a light cup body (20), and the bracket (10) is formed with a base (12) and a plurality of conductive pins (14), wherein, the conductive pins (14) can extend horizontally relative to the base (12), so that the packaging support structure has a thinner design, and can be used in thinner screens and televisions, etc. The conductive pin (14) can also be bent relative to the base (12), so that the packaging support structure is suitable for different design occasions. The support (12) has a front and a back, and the front of the support (10) A protruding part (122) is formed on the base (12), so that there is a difference between the base (12) and the conductive pin (14), which is not coplanar, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com