Vehicle front-end for mounting to the front face of a track-bound vehicle, in particular a rail vehicle

A technology for rail vehicles and railway vehicles, which is applied to railway car body components, railway vehicle wheel guards/buffers, railway car bodies, etc., and can solve car body structure deformation, car body damage, and insufficient shock absorption effect of shock absorbers and other problems to achieve the effect of avoiding collapse and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

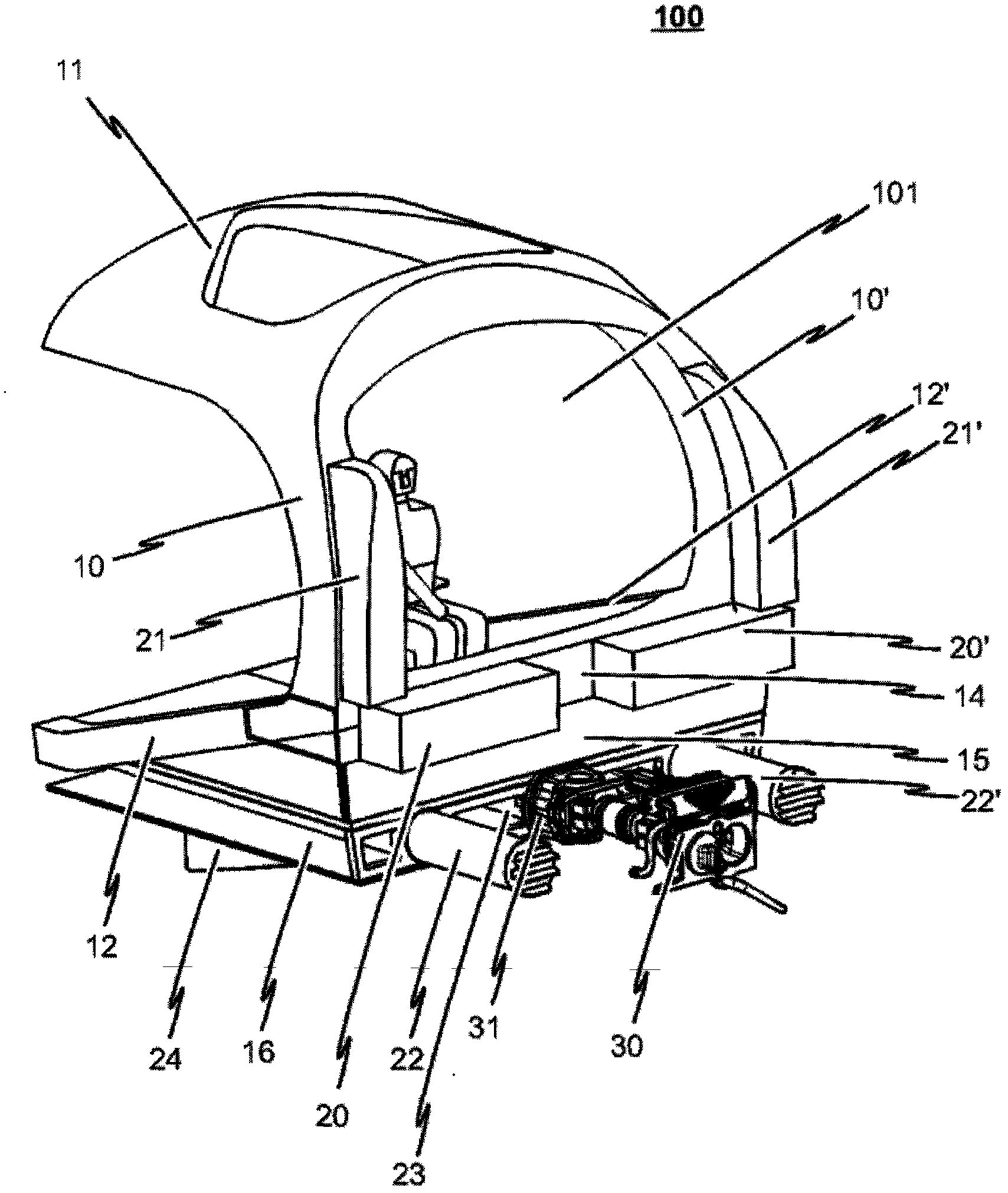

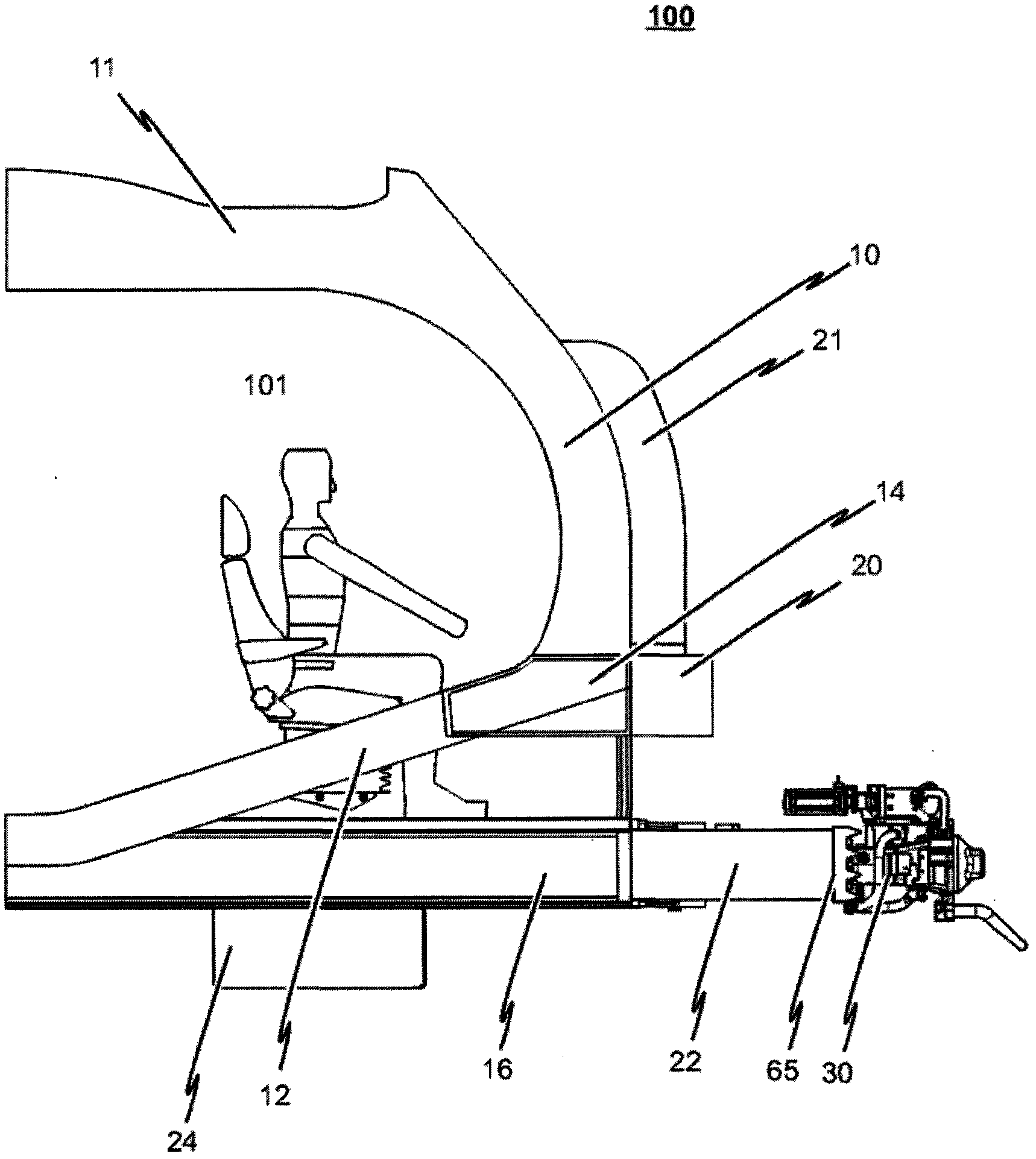

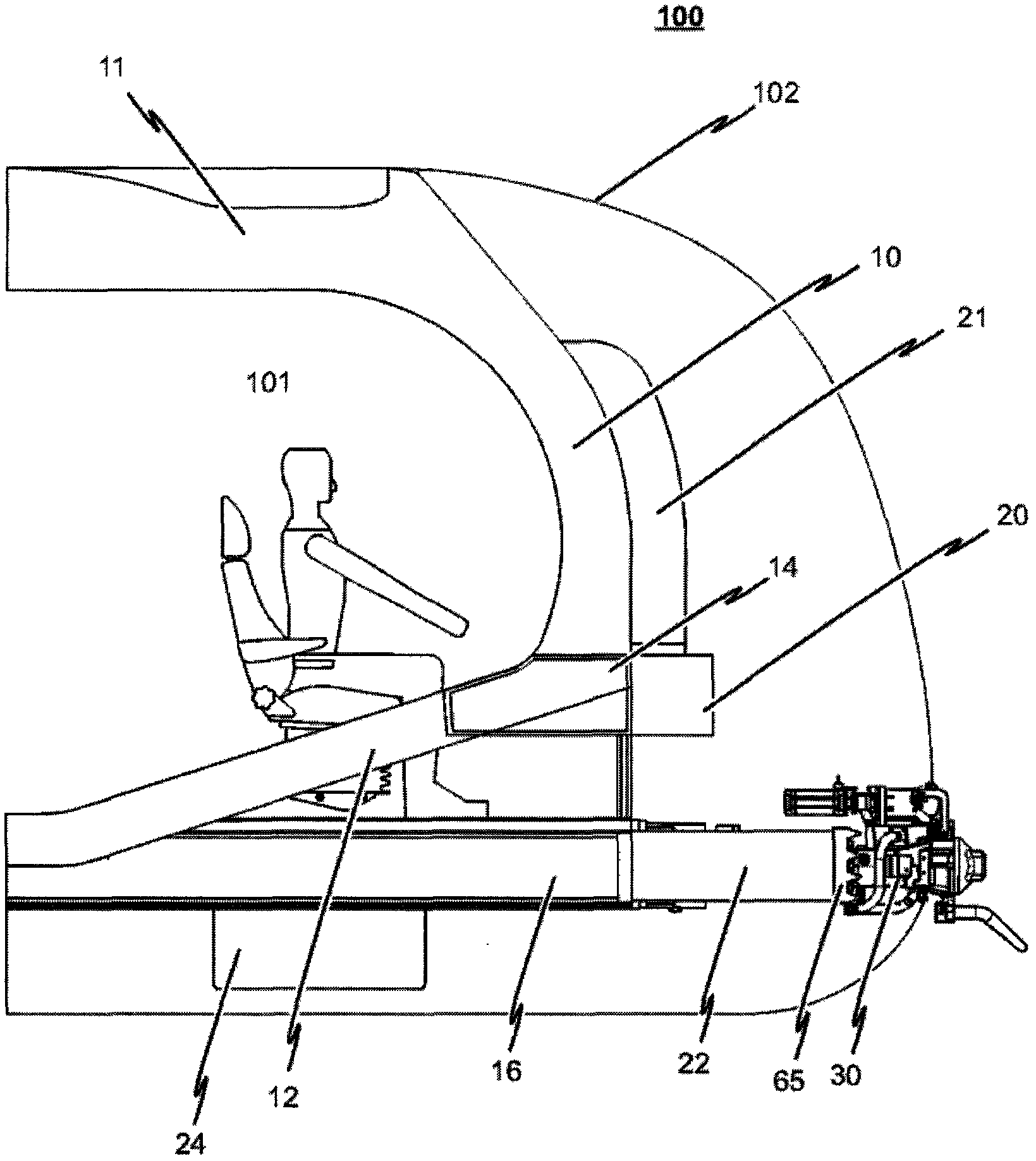

[0069] The vehicle front module structure 100 used in the vehicle front module provided in the first embodiment of the present invention will be described below with reference to the accompanying drawings.

[0070] figure 1 It is a schematic diagram of the vehicle front module structure 100 in the first embodiment of the present invention. figure 2 for figure 1 A schematic side view of the front module structure 100 of a medium vehicle. image 3 For the first embodiment with figure 1 or figure 2 Schematic side view of the vehicle front module in the middle vehicle front module structure 100 and implying the exterior design 102 .

[0071] Correspondingly, the vehicle front module structure 100 in this embodiment is designed to be installed at the front of the rail vehicle (not shown). The vehicle front module structure 100 is entirely composed of structural elements, cf. Figure 4-18 , the structural elements will be described in detail below. These structural elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com