Nickel positive electrode for fiber battery

一种镍正极、电池的技术,应用在电池电极、碱性蓄电池电极、镍蓄电池等方向,能够解决没有达到实用的水平等问题,达到高容量、实现寿命、长寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

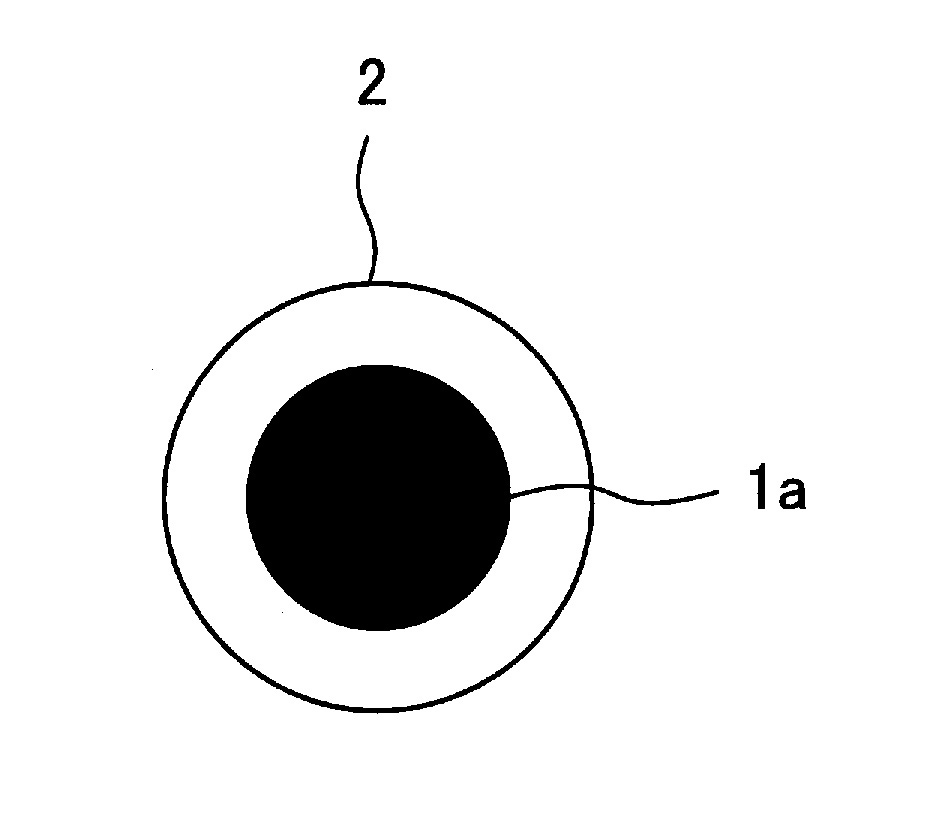

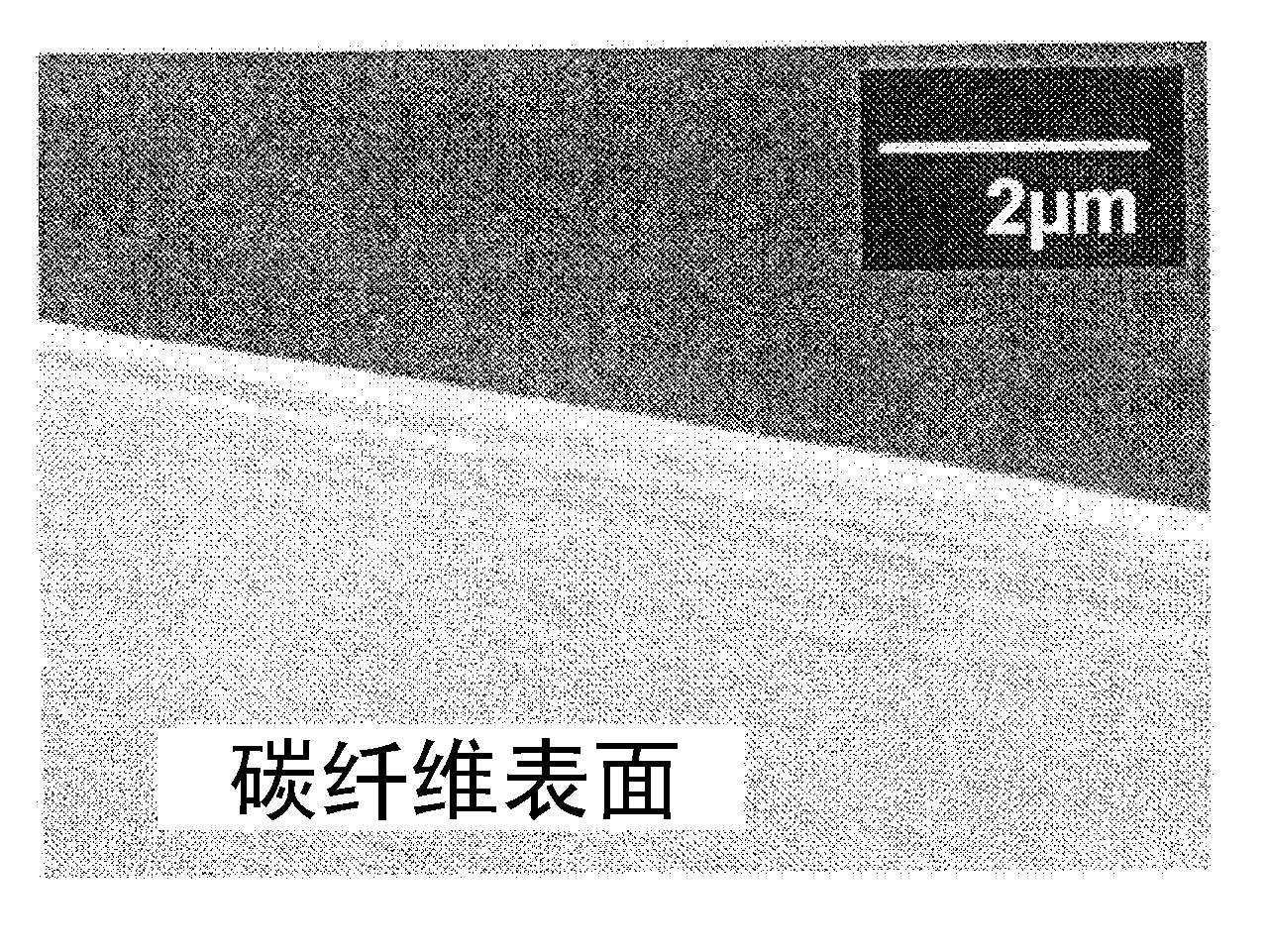

[0091] Graphite fibers (fibers obtained by twisting two commercially available polyacrylonitrile fibers and then graphitized) constituting the current collector were fibers with an average diameter of 12 μm. The average diameter of each individual fiber constituting the fiber was 6 μm.

[0092] Nickel-boron alloy plating (containing 1% boron) was carried out on the graphite fiber by the precipitation method of nickel-boron alloy plating (containing 1% boron) using the reducing action of dimethylamine borane. After electroless nickel plating, nickel was plated by an electroplating method. The electroplating solution for electroplating nickel uses a so-called Watts solution mainly composed of 350 g / liter of nickel sulfate, 45 g / liter of nickel chloride, and 42 g / liter of boric acid. Specifically, 3000 graphite fibers with a length of 50 mm were sandwiched between two foamed nickel sheets, fixed by crimping, and put into Watt's solution as a joint. In addition, a nickel plate wi...

Embodiment 2

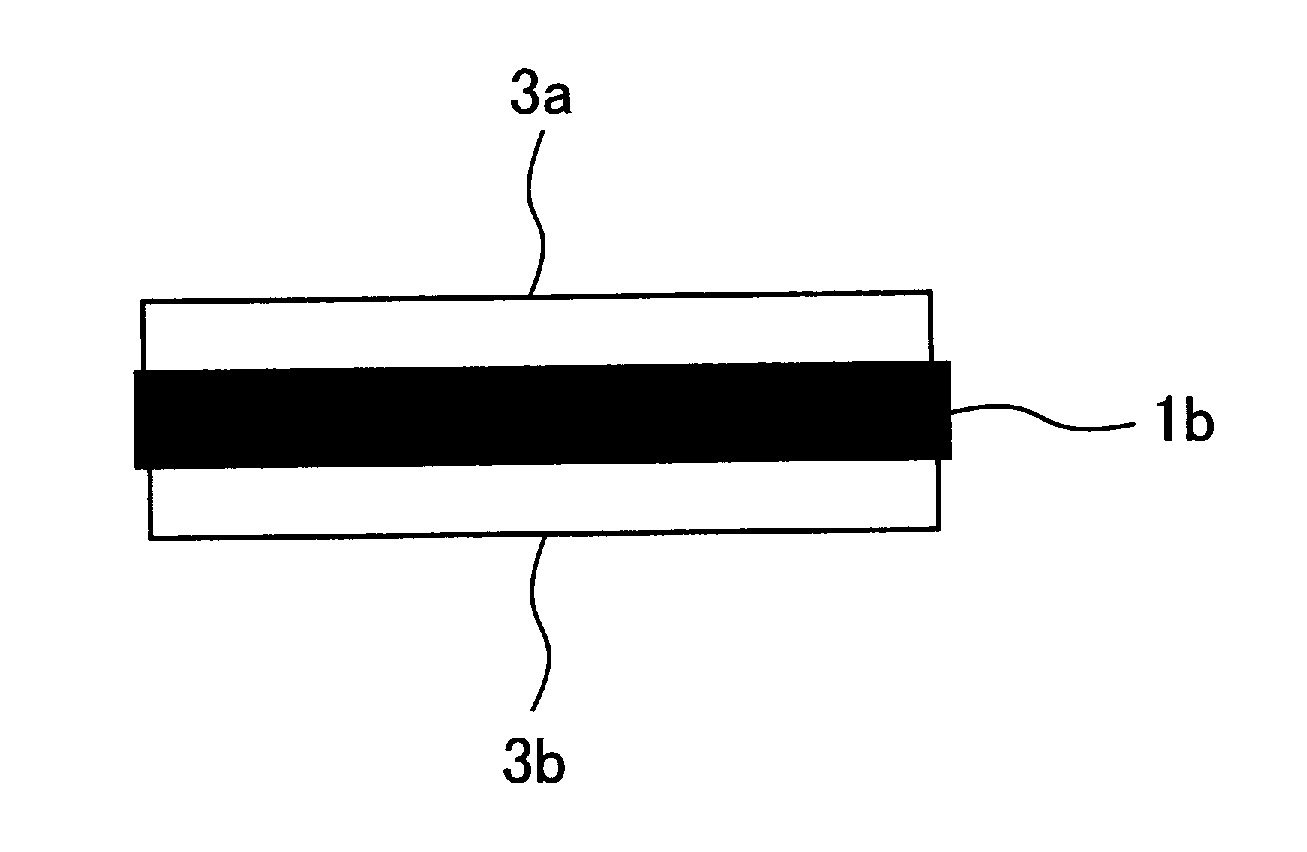

[0124] In order to investigate the effect of adding aluminum hydroxide to nickel hydroxide, 1600 g of nickel nitrate (6 hydrate) and 420 g of aluminum nitrate (9 hydrate) were added to 5000 g of water, and the pH was adjusted to 5 to obtain a solution for electrolysis. In this solution, the nickel-plated fibrous current collector obtained in the same manner as in Example 1 is disposed as a cathode, the nickel plate is disposed as an anode, and a polypropylene non-woven fabric is disposed as a separator between the two electrodes to perform electrolysis. . Electrolysis condition is current density 20mA / cm 2 , The electrolysis time is 10 minutes. In this case, nickel hydroxide and aluminum hydroxide were electrolyzed with an electrolysis efficiency of about 42%. The content of aluminum hydroxide was 22 mol% in terms of metal (that is, aluminum relative to nickel). The mixed layer of nickel hydroxide and aluminum hydroxide electrolytically deposited on the fibrous current coll...

Embodiment 3

[0130] In order to investigate the effect of adding conductive agent and binder to nickel hydroxide, 2000g of nickel nitrate (6 hydrate), 85g of granular carbon material, and 21g of PVA were added to 5000g of water, adjusted to pH=5, and obtained Solution for electrolysis. In this solution, the nickel-plated fibrous current collector obtained in the same manner as in Example 1 is disposed as a cathode, the nickel plate is disposed as an anode, and a polypropylene non-woven fabric is disposed as a separator between the two electrodes to perform electrolysis. , the condition of electrolysis is that the current density is 20mA / cm 2 , The electrolysis time is 10 minutes. In this case, the granular carbon material and PVA were precipitated simultaneously with nickel hydroxide electrolysis, and the electrolysis efficiency was about 39%. The content of the particulate carbon material was 20% by weight. The average thickness of the mixed layer of nickel hydroxide, granular carbon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com