Jet type fertilizer injector with oscillation cavities

An oscillating cavity and jet-type technology, applied in the field of farmland irrigation, can solve the problems of increased system operation difficulty, low efficiency, high energy consumption, etc., and achieve the effect of simple structure, reduced energy consumption, and no mechanical failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

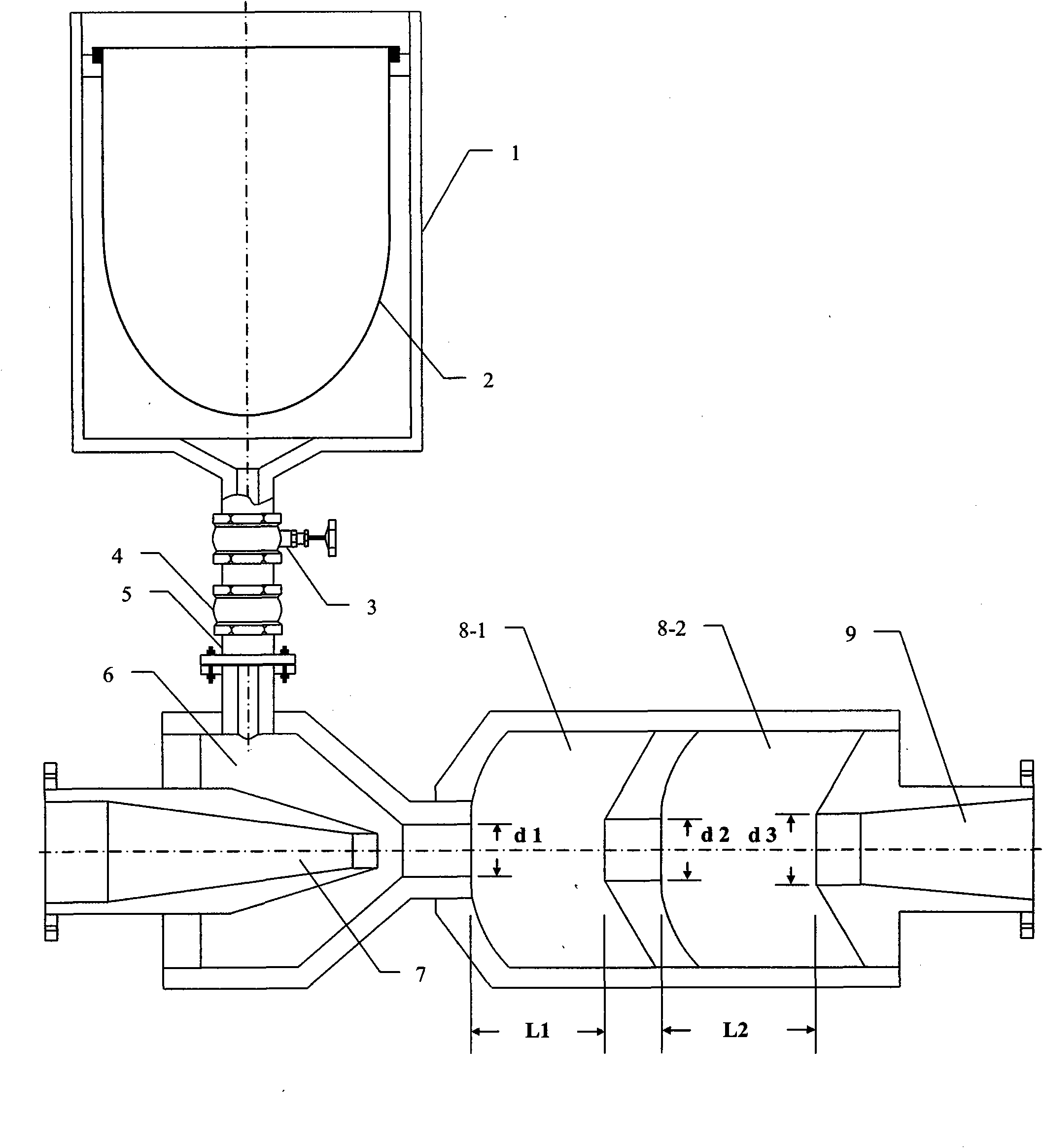

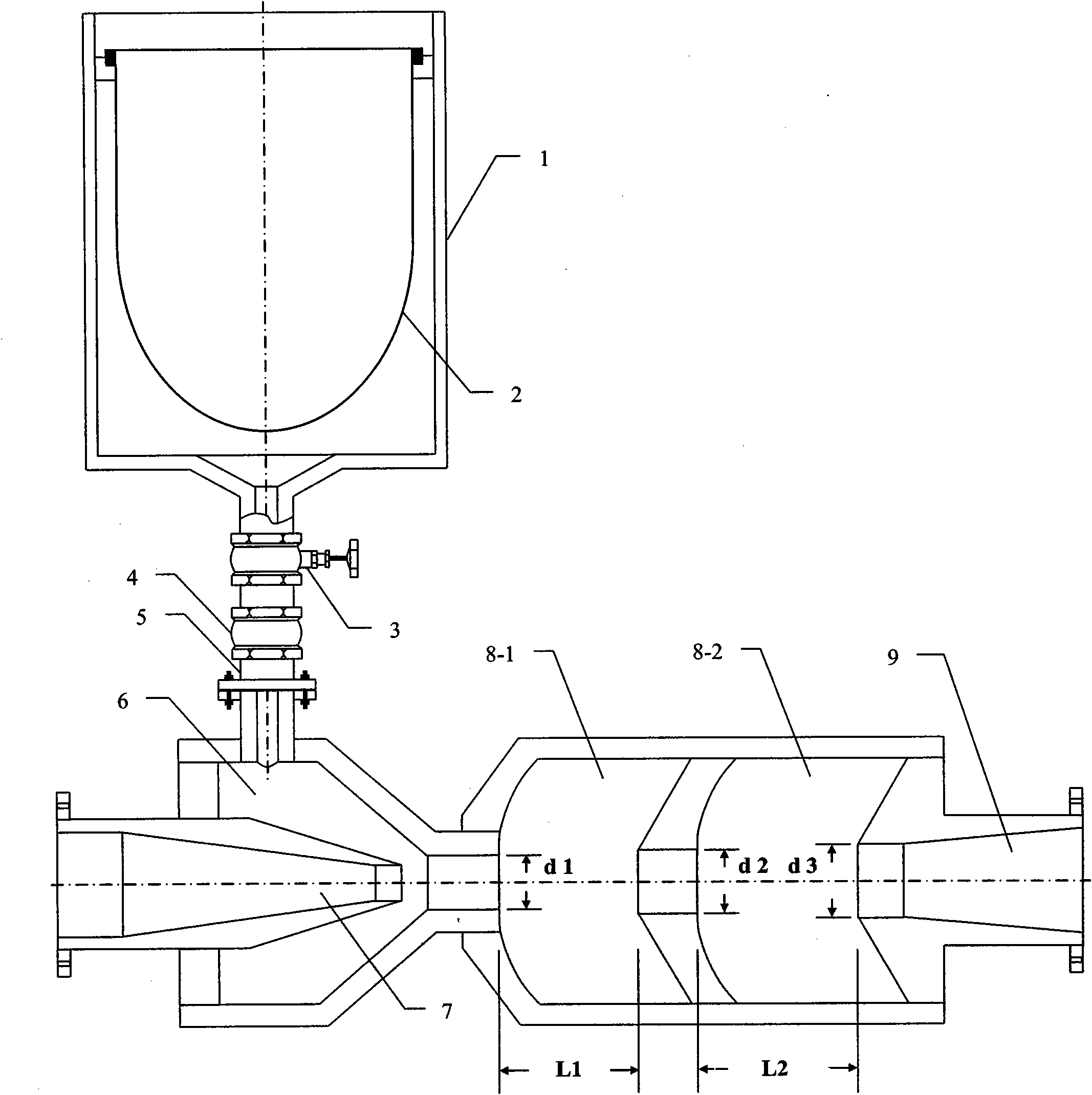

[0018] A jet-type fertilizer injection device with an oscillating cavity, as shown in the accompanying drawings, includes: a filler cavity 1, a filler cavity filter screen 2, a feed gate valve 3, a check valve 4, a feed pipe 5, a fertilizer injection cavity 6, Jet nozzle 7, primary oscillating cavity 8-1, secondary oscillating cavity 8-2, gradual flow channel 9, packing cavity 1 is barrel-shaped, placed vertically with the mouth facing upwards, and has a hard and detachable filter in the packing cavity 2. The bottom of the filling chamber 1 is connected to the feed end of the upper part of the fertilizer injection chamber 6 through the feed gate valve 3, the check valve 4, and the feed pipe 5, and the end of the jet nozzle 7 with a large overflow section is connected to the water pump of the main pipeline of the irrigation system One end of the water outlet is connected, and the end of the jet nozzle 7 with a small flow section (jet port) penetrates horizontally into the interi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com