Oil and water/gas two-stage separator for braking gas

A stage separation and shell technology, which is applied in the field of oil and water/air double-stage separators for brake gas, and can solve the problem of insufficient capacity of molecular sieves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

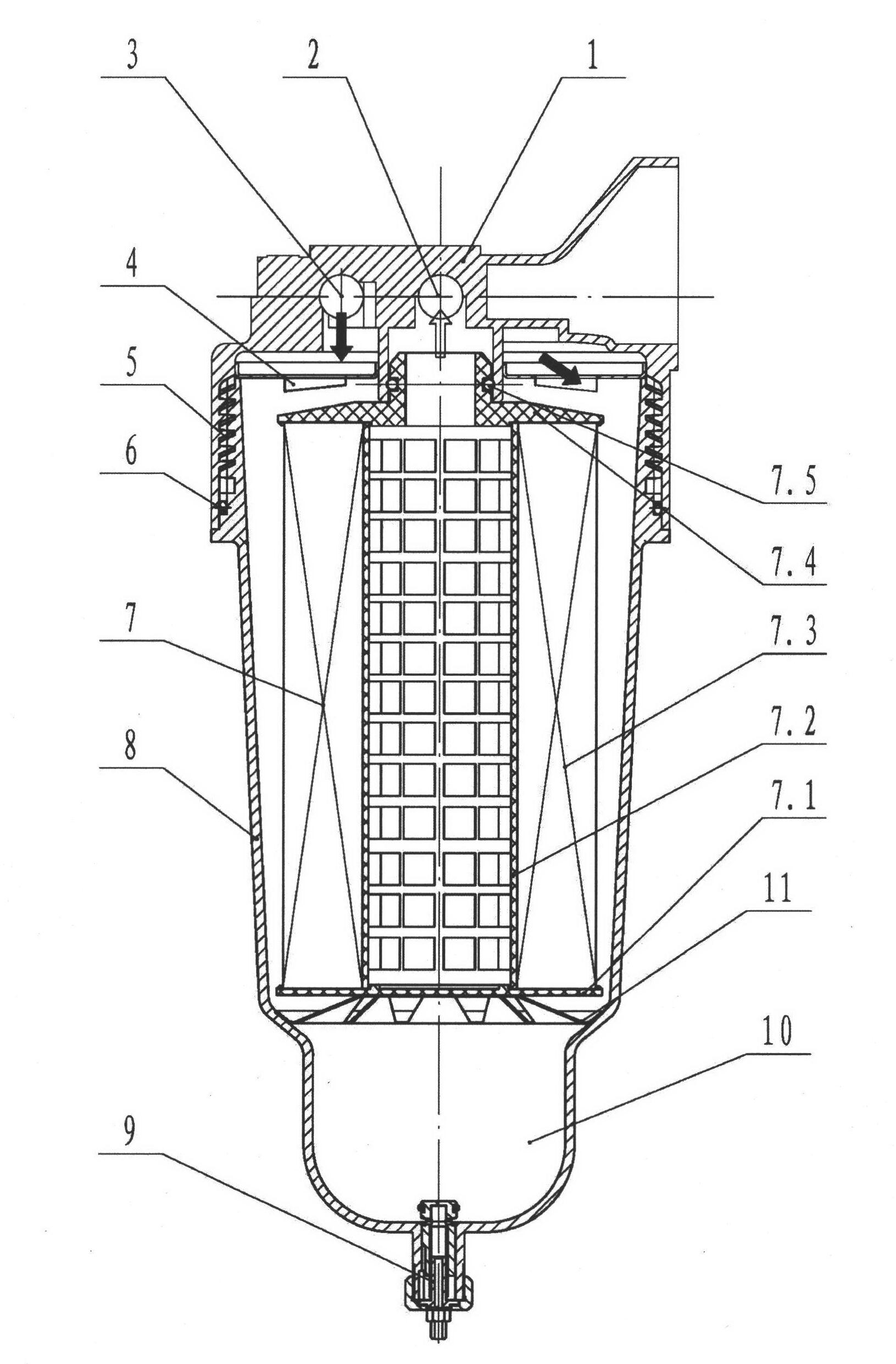

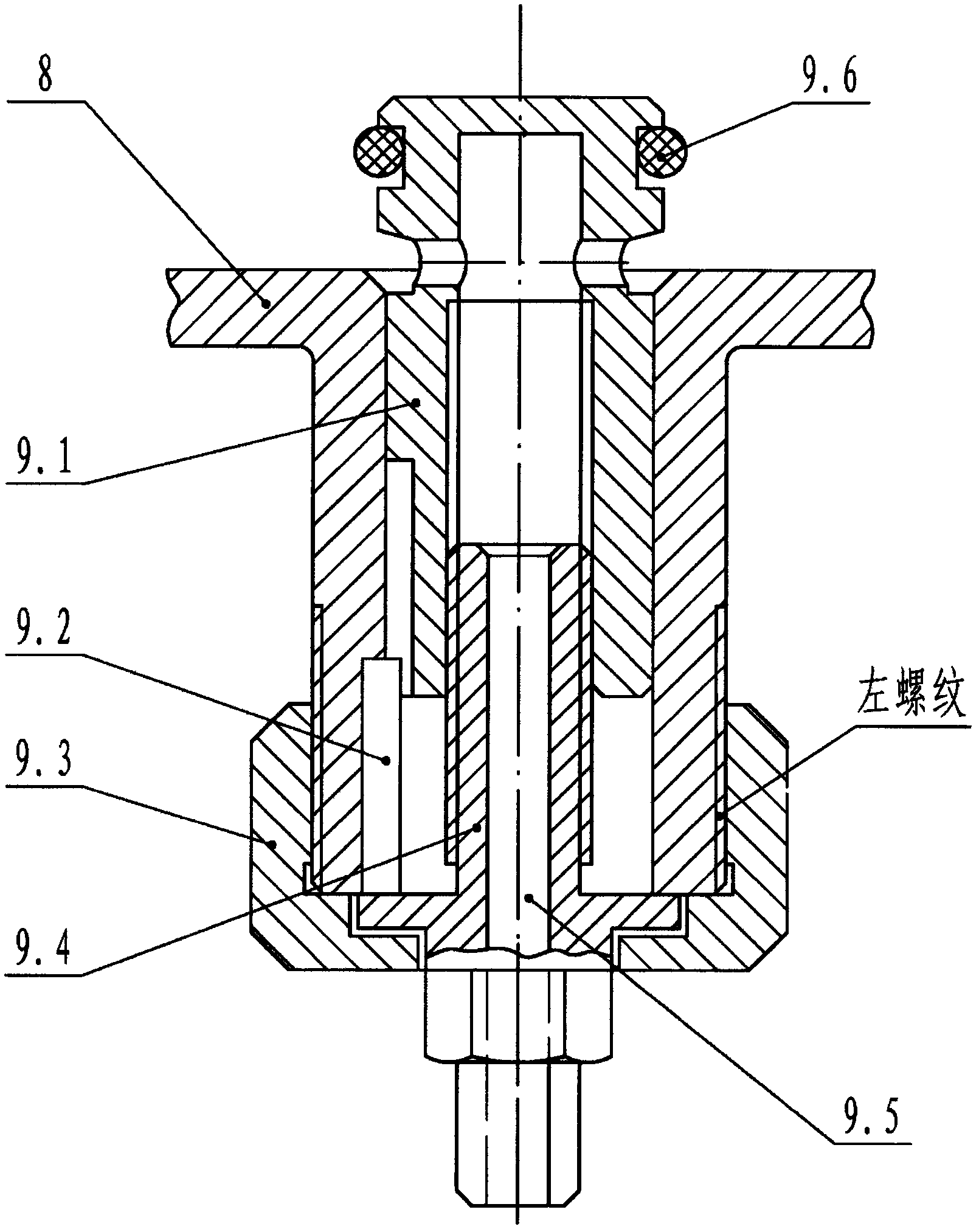

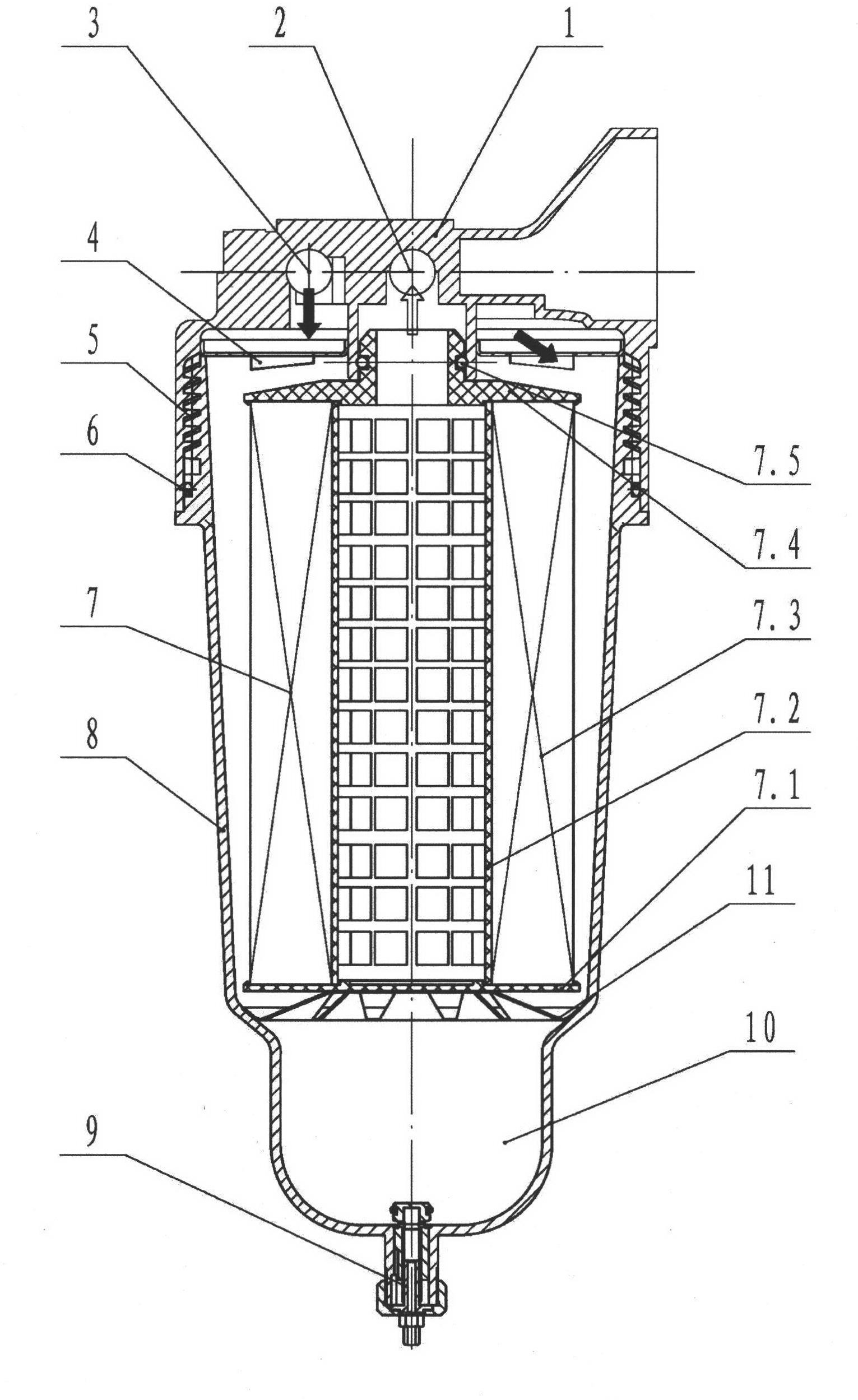

[0017] Embodiment 1, see attached figure 1 And attached figure 2 , The oil and water / air double-stage separator of brake gas includes: base 1, housing 8, filter element assembly 7, O-shaped rubber sealing ring 6, and a guide vane 4 is set inside the base, The upper end cover 7.4 of the filter element assembly is set on the air outlet channel 2 in the base. There is a disc spring 11 under the lower end cover 7.1. The edge of the disc spring is embedded in the positioning groove in the housing 8. The upper and lower ends of the filter element assembly There is a support frame 7.2 between the covers, and the support frame is covered with a multi-fold filter paper 7.3. The filter paper system has a strong function of repelling water and oil through organic silicon surface treatment. The upper part of the housing is connected with the base 1 through the anti-loosening thread, the lower end of the housing is provided with a sewage tank 10, and the lower end of the housing is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com