Production method for wound and attached steel wire crown band ply of all-steel radial-truck meridian tire

A production method and technology for radial tires, which are applied in the field of tire molding and manufacturing, can solve the problems of discontinuous tire ground contact pressure distribution, increased thickness of zero-degree lap joints, and difficulty in controlling calendering tension, so as to achieve uniform ground contact pressure distribution and wear. , Improve production efficiency and ensure the effect of imprinting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

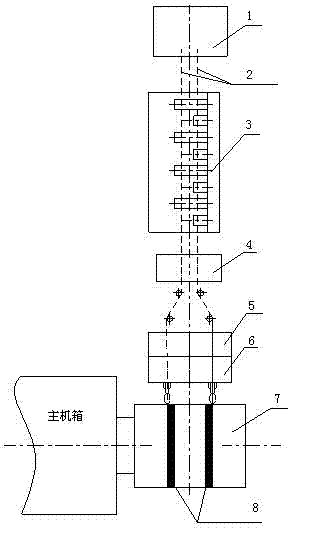

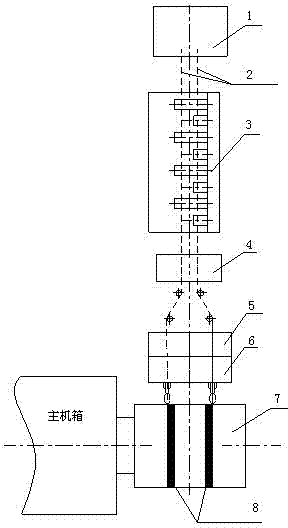

[0012] Such as figure 1 As shown, the steel wire narrow crown strips 8 are two wound on the I-shaped wheel and have been glued to the width of two or more steel wires 2. The steel wires 2 are guided by the guide device 1 and stored by the storage device 3 Finally, two layers of cap strips 8 with a width of 30 mm are spirally wound by the cap strip winding device 5 on the belt shoulder. The crown strip winding system consists of a guide device 1, a storage device 3, a tension control device 4, a winding device 5 and a cutting device 6.

[0013] Two steel wire crown strips 8 coated with rubber are wound in the same I-shaped wheel. The steel wire crown strips 8 are guided by the unwinding device 1 and then directly enter the storage device 3. The storage is enough to meet the high-speed winding paste Timely material.

[0014] The storage device 3 is composed of two sets of storage rollers whose working processes are independent of each other, so as to realize the independent st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com