Producing method of novel cross-steaming wine related in white spirits

A production method and a new type of technology, applied in the production of string steamed wine and in the field of wine brewing, can solve the problems of insufficient utilization of science and rationality, insufficient richness and balance of nutrients, and single variety and flavor of wine products, so as to facilitate widespread popularization and application , resource saving, rich flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

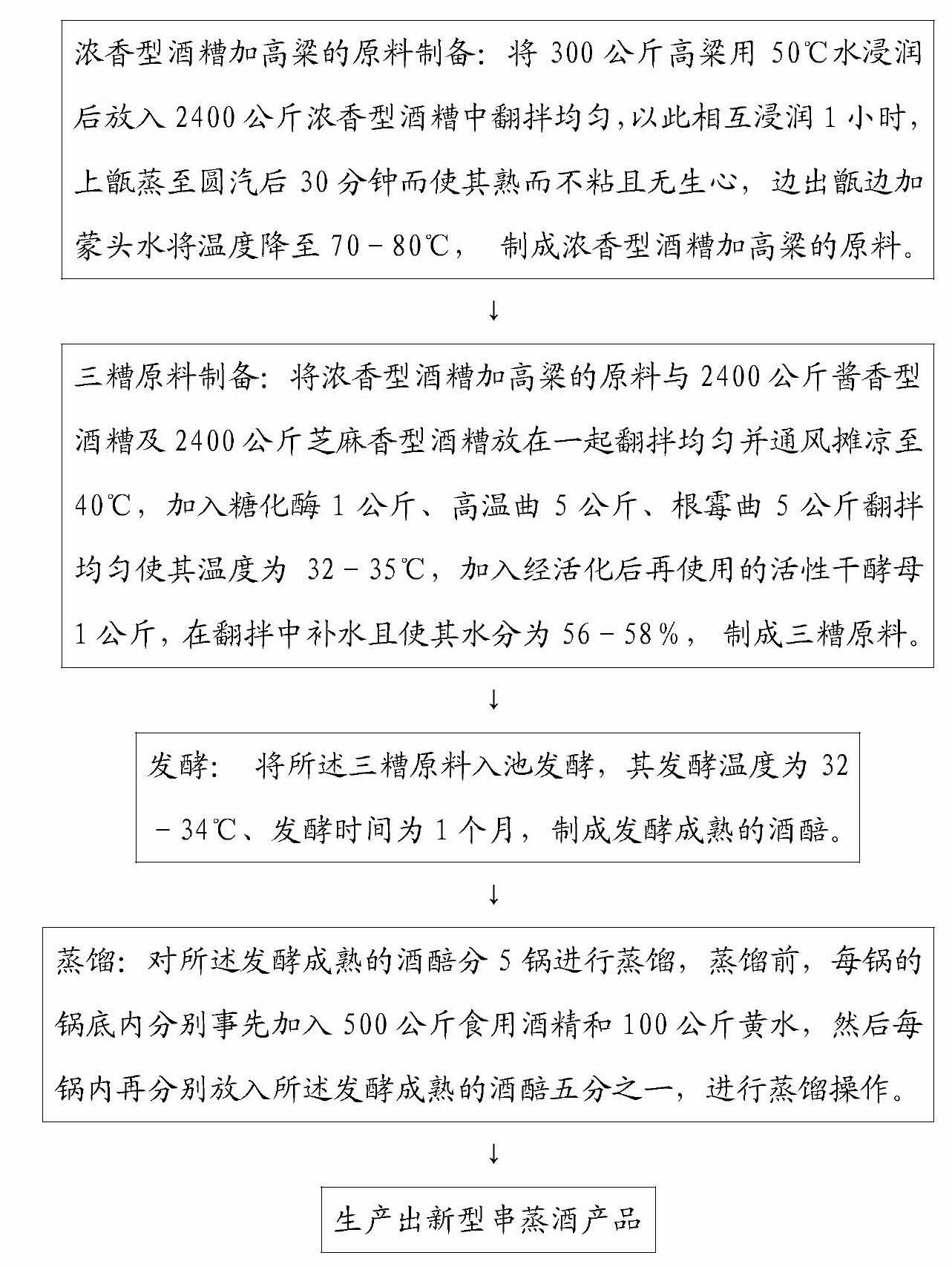

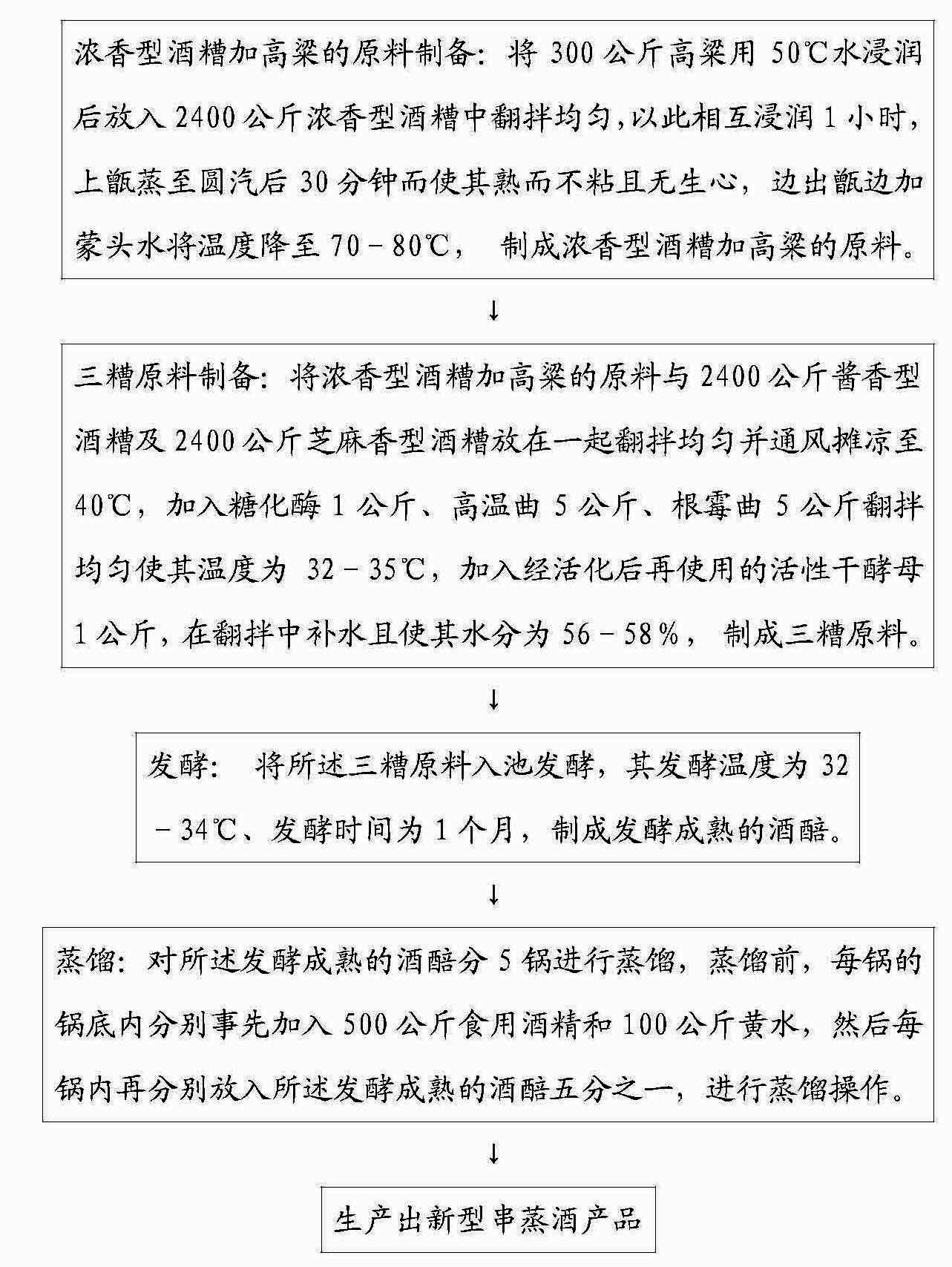

Method used

Image

Examples

specific Embodiment approach 2

[0036] Carry out according to specific embodiment 1, only on the specific implementation basis of specific embodiment 1, carry out with shrinking 10,8,5,3,2,1 times respectively, also expand 1,3,5,8, respectively 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100, 150, 200, 250, 300, 500, 600, 800, 1000 times to implement, thus Experiments of different scales, such as small-scale experiment, a fermentation cellar-scale experiment, medium-scale experiment, large-scale experiment, and productive experiment, have been carried out, all of which have obtained expected good results. The present invention obtains the solid foundation for the implementation of the different-scale tests, and creates solid conditions for future production promotion and application.

[0037]After the production of the present invention, a trial assessment was carried out. After passing the trial assessment, experts in the industry agreed that this production method is a great innovation in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com