Method for preparing esterifying solution required in culture of cellar mud for Luzhou-flavor liquor

The technology of strong-flavor liquor and esterification liquid is applied in the field of brewing and brewing pit mud, which can solve the problems that affect the aroma and taste components of wine products to generate high-quality wine yield, etc., and achieve stable and reliable effects and scientific nutritional ingredients. Reasonable and easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

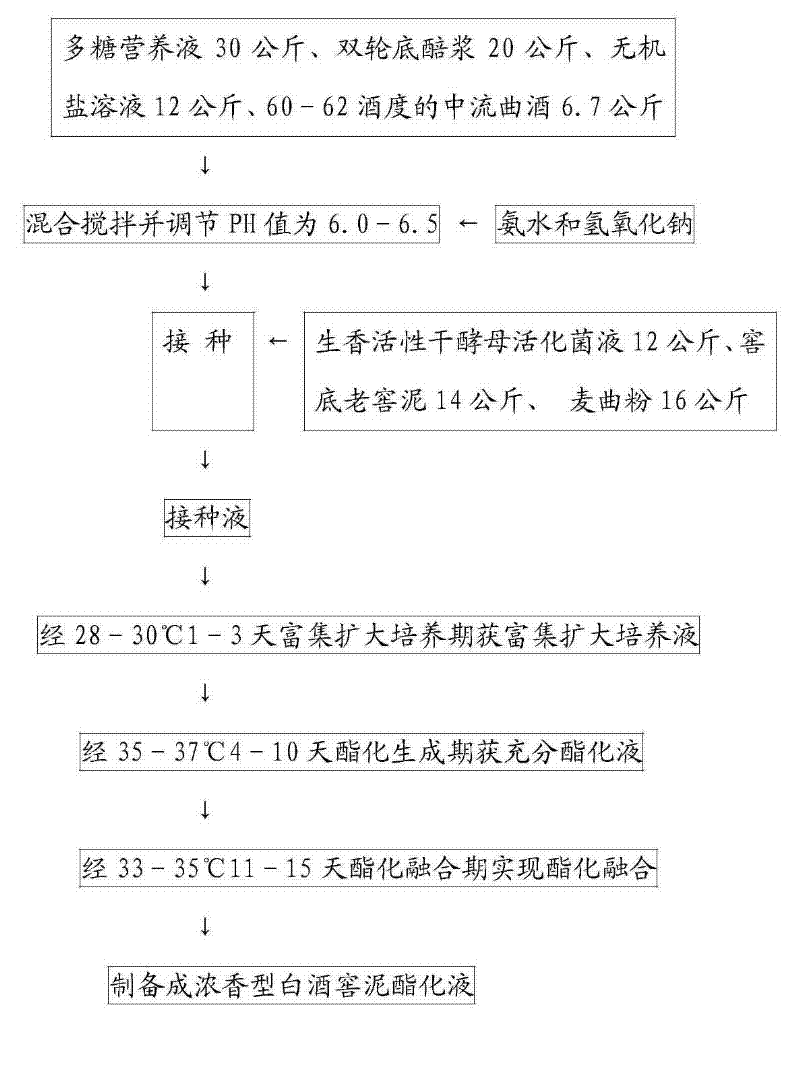

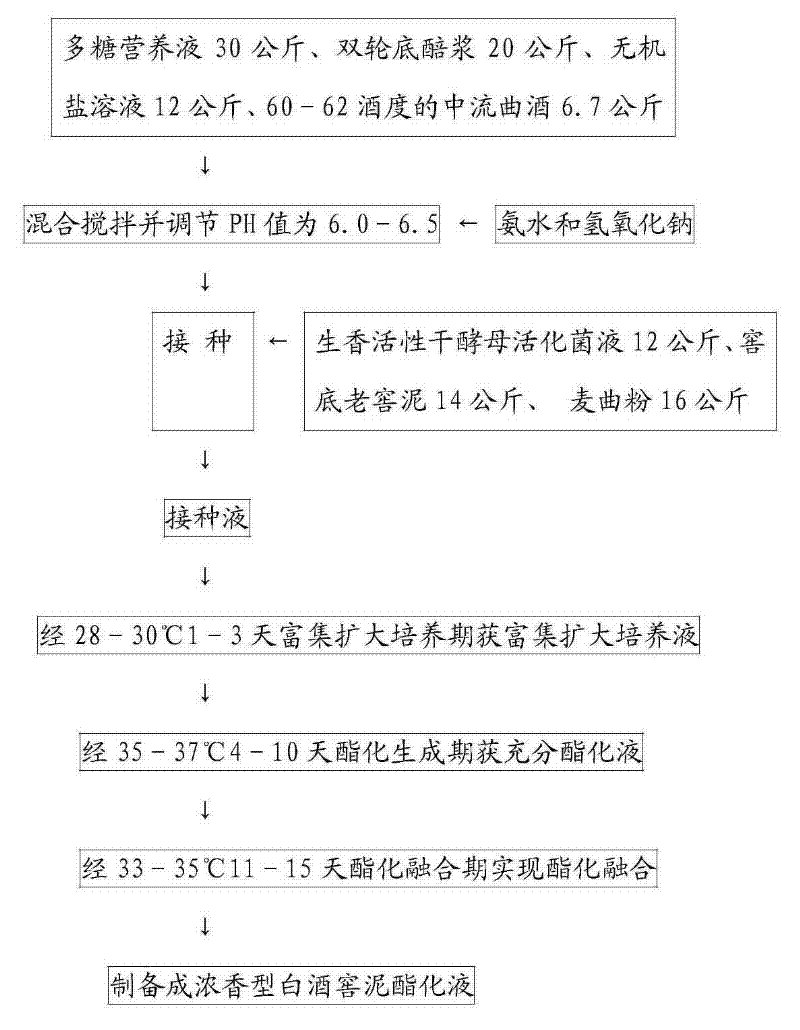

Image

Examples

preparation example Construction

[0034] ①. Preparation of polysaccharide nutrient solution: put 100 kg of corn flour / rice into 300 kg of water and boil for 30-40 minutes, then cool to 55-60°C, add 0.1 kg of glucoamylase and 10 kg of medium-temperature wheat yeast powder and mix them at 50 Insulate and saccharify at -55°C for 3-4 hours, then heat up to 85°C, then cool to 26-28°C to prepare a polysaccharide nutrient solution, and take out 30 kg of the polysaccharide nutrient solution for later use;

[0035] ②. Preparation of Shuanglunbottom fermented grains slurry: Prepare Shuanglunbottom distiller's grains and water in a ratio of 1:4 after distilling wine, stir and boil for 20 minutes, then cool rapidly to below 35°C To obtain the boiled grains water slurry, take out 10 kg of the boiled grains water slurry and add 10 kg of fermented and undistilled double-wheel bottom fermented grains to obtain 20 kg of double-wheel bottom fermented grains for subsequent use;

[0036] ③. Preparation of aroma-generating active dr...

specific Embodiment approach 2

[0045] Carry out by specific embodiment one, just on the basis of specific embodiment one, carry out multiple repeated implementation and carry out the detection of each index simultaneously with reducing 30, 25, 20, 15, 10, 5 times respectively, obtained expected good Effect: Make the present invention have solid small-scale test, expand test basis.

specific Embodiment approach 3

[0046] Carry out according to specific embodiment one, just carry out multi-repetition implementation and carry out the detection of each index simultaneously with expanding 1, 3, 5, 7, 10, 15, 20, 25, 30 times respectively on the basis of specific embodiment one , obtain expected good effect; make the present invention have solid re-enlargement test, production-type test basis, and lay a solid foundation for specific application and implementation in brewing production.

[0047] The present invention has carried out probation assessment after finishing, and in probation assessment, the main technical index result of applying the present invention to make pit mud shows: the available nitrogen (mg / 100g dry soil) of applying pit pit mud of the present invention is 489.8, compares contrast The 330.9 of the test group is higher than 158.9, and the available potassium (mg / 100g) dry soil of the application pit mud of the present invention is 662.6, 454.6 higher than the 208 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com