Lifting apparatus for ship

A technology for lifting equipment and ships, applied in the direction of ship lifting devices, vertical lifting ship machinery, water conservancy projects, etc., can solve the problems of complex overall structure, inconvenient and free, high production cost, etc., to simplify the structure, reduce the weight of the structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

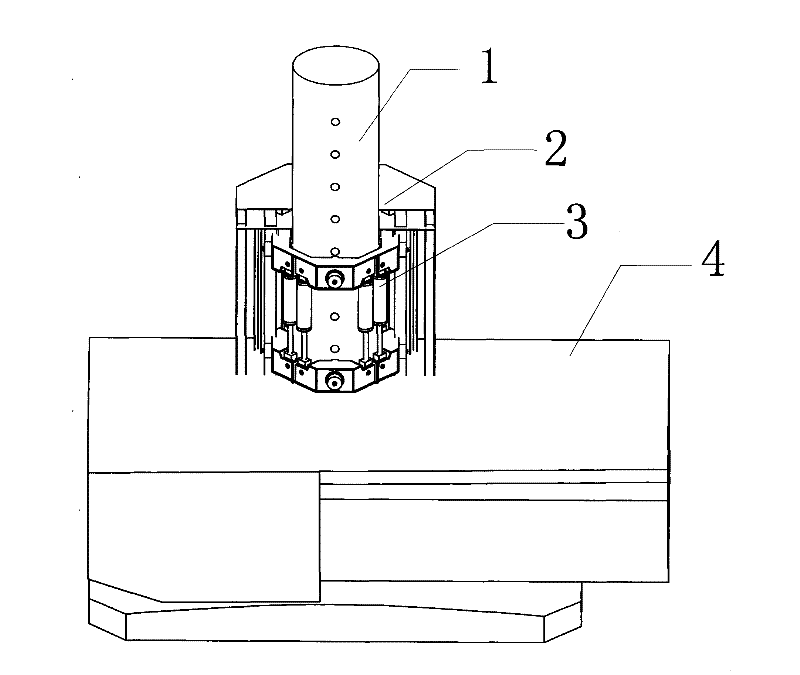

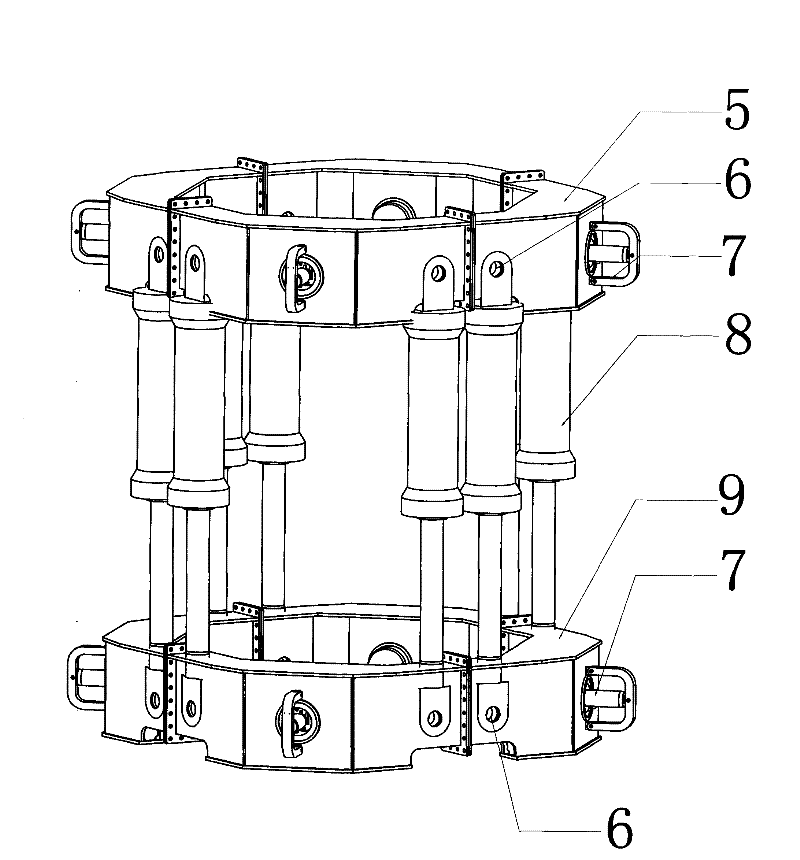

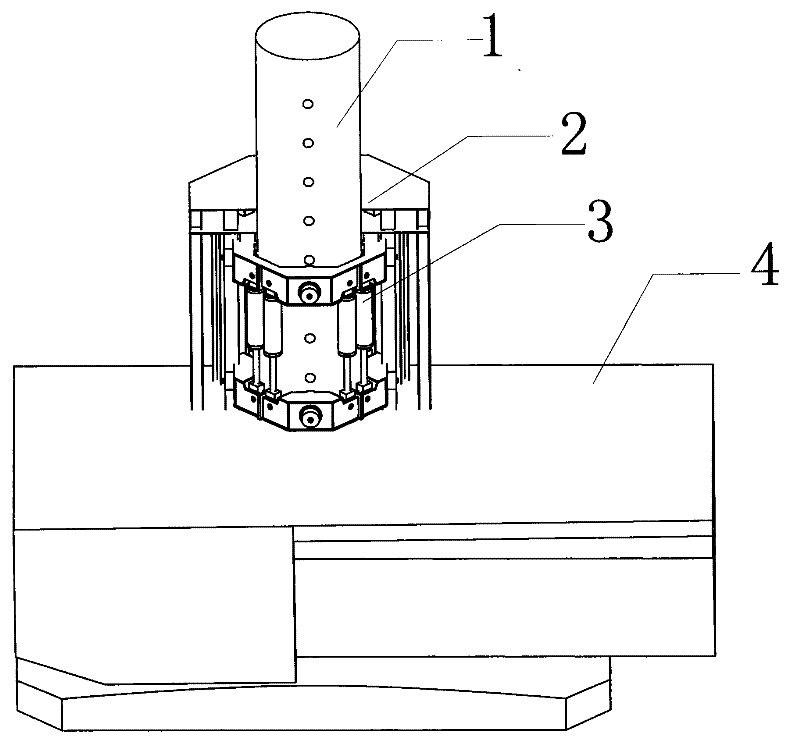

[0012] The present invention will be further described below in conjunction with all accompanying drawings, and the preferred embodiment of the present invention is: a kind of lifting equipment for ship described in this embodiment, it comprises spud can 1, installation tower 2, ring beam type hydraulic pressure Lifting device 3, hull 4, wherein, the spud shoe 1 of the present invention is located in the ring beam hydraulic lifting device 3, and the spud shoe 1 is provided with four rows of evenly arranged pin holes, which are used to cooperate with the ring beam hydraulic lifting device The bolt cylinder 7 on the 3 is matched, and then the spud shoe 1 of the present invention is connected with the ring beam hydraulic lifting device 3 through the bolt cylinder 7; the installation tower 2 is fixedly connected with the hull 4; the ring beam hydraulic lifting device 3 passes through The elastic pad is connected with the installation tower 2, and the ring beam type hydraulic liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com