Fuel high-pressure pump applied in internal combustion engine

A technology of high-pressure pump and internal combustion engine, applied in the direction of fuel injection pump, fuel injection device, special fuel injection device, etc., can solve the problem of short switching time of the quantity control valve, and achieve the effect of simplifying the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

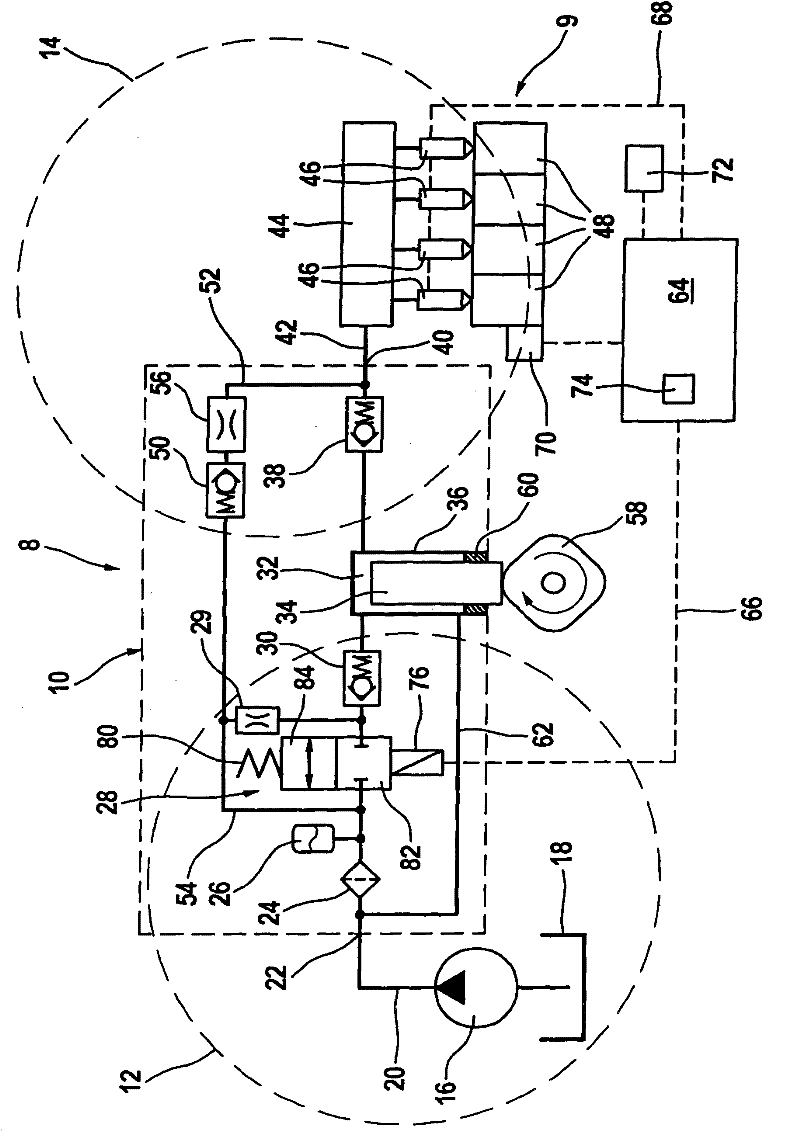

[0019] figure 1 A fuel system 8 for an internal combustion engine 9 is shown, provided with a high-pressure fuel pump 10 . The fuel system 8, as will also be described, is divided into figure 1 A low pressure region 12 is shown on the left and a high pressure region 14 is shown on the right. A delivery pump 16 arranged in the low-pressure region 12 pumps fuel with delivery pressure from the fuel storage container 18 via a low-pressure line 20 into an inlet connection 22 of the high-pressure fuel pump 10 . A filter 24 and a pressure damper 26 are arranged in the low-pressure region 12 of the fuel. The pressure damper 26 damps pressure fluctuations present on the low-pressure side of the high-pressure fuel pump 10 and enables a high delivery rate also at high rotational speeds and cam speeds.

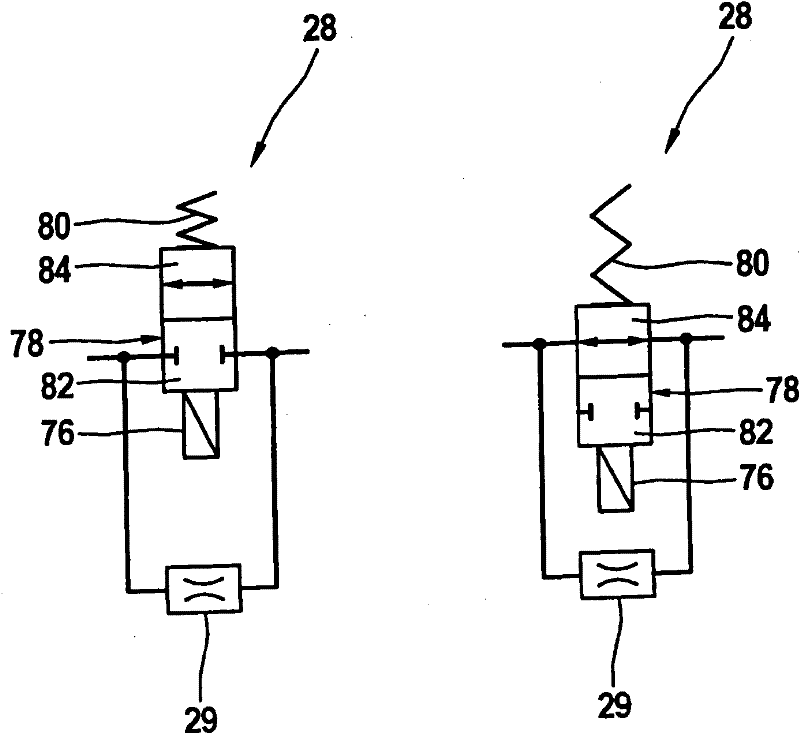

[0020] Fuel is sucked into a working chamber 32 of the high-pressure fuel pump 10 via the switching valve 28 and subsequently an inlet valve 30 . In this connection, the switching val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com