Composition for Recovering Bitumen from Oil Sands

a technology of oil sands and compositions, applied in the direction of dissolving, mixing, chemistry apparatus and processes, etc., can solve the problems of complex physical and chemical changes that break the surface tension between hydrocarbons and water components, large amount of energy that is required for heating the hot water used for bitumen separation from the ore, and inactivity, etc., to achieve cost-benefit, increase the base rate of recovery, and increase the temperature and/or the amount of compositions employed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

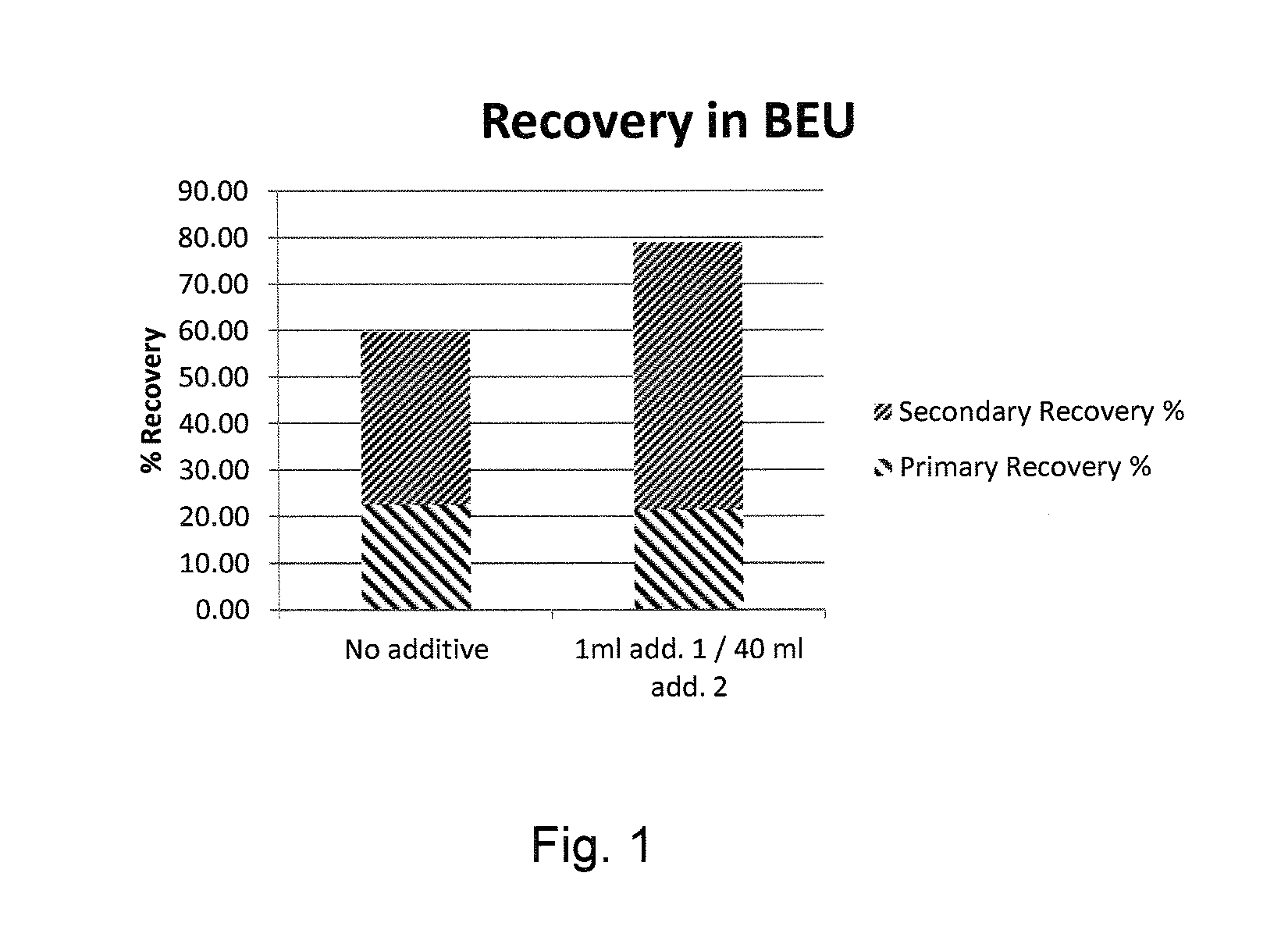

Image

Examples

Embodiment Construction

[0033]The following description is provided to enable any person skilled in the art to make and use the invention and sets forth the best modes contemplated by the inventor of carrying out his invention. Various modifications, however, will remain readily apparent to those skilled in the art, since the general principles of the present invention have been defined herein specifically to provide an improved and environmentally safe composition for recovering bitumen from oil sands.

[0034]As used herein, the term “about” means “approximately,” and, in any event, may indicate as much as a 10% deviation from the number being modified.

[0035]Process

[0036]As explained in more detail below the current composition is directly useable in the current CHWE process. However, it somewhat modifies the way in which the process attains its results. The most apparent differences and advantages are the need for much lower amounts of energy because the water temperature is much lower and the use of envir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com