Control mechanism of automobile manual transmission

A manual transmission and operating mechanism technology, applied in mechanical equipment, components with teeth, transmission control and other directions, can solve the problem that the selection stroke and selection force are not easy to control, increase the processing cost of the shift shaft, and the size of the selection force. Inconsistency and other problems, to achieve the effect of easy control of the selection force, saving installation space, and good return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

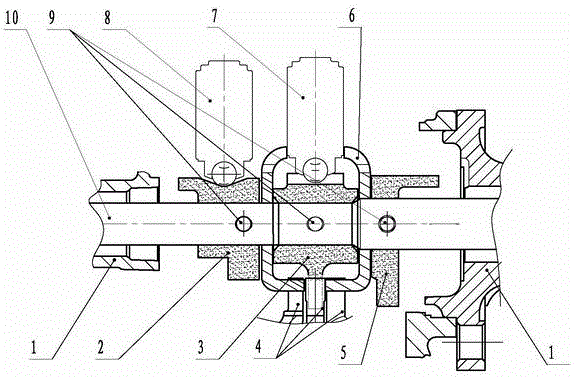

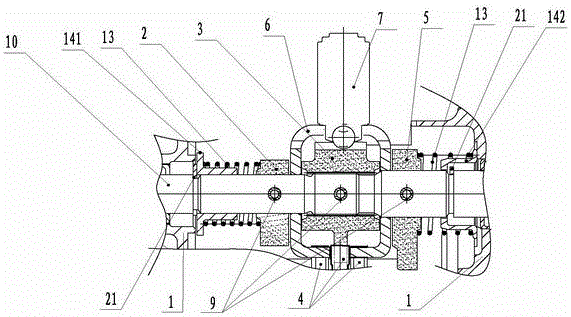

[0027] figure 1 Shown is a control mechanism of an automobile manual transmission, which includes a shift shaft 10, a gear selection interlock block 2, an elastic pin 9, a shift dial block 3, a shift interlock plate 6, a housing 1, and a gear selection positioning seat 8 and shift positioning seat 7.

[0028] The gear selection interlock block 2 and the shift dial block 3 are fixedly connected to the shift shaft 10 through elastic pins 9 respectively. There is no relative movement between the gear selection interlock block 2, the shift paddle 3 and the shift shaft 10, that is, the gear selection interlock block 2 and the shift pad 3 move correspondingly with the movement or rotation of the shift shaft 10 or turn.

[0029] The gear selection interlock block 2 is provided with two curved surfaces and a reverse gear interlock dial; the two curved surfaces have the same curvature and are symmetrically distributed in a "V" shape between the two; the shift block 3 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com