Variable valve gear and method of controlling same

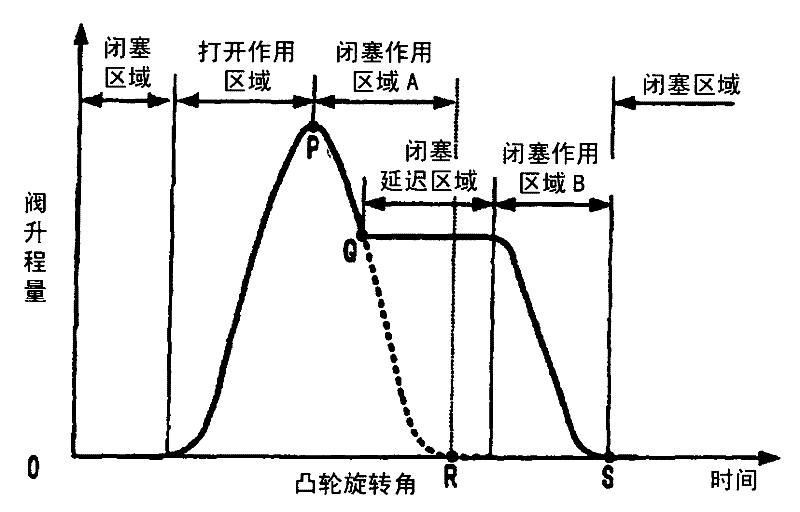

A control method and technology of valve device, applied in valve device, electrical control, engine control and other directions, can solve the problems of timing deviation of suction valve fully closed, delayed return of spool valve, slow return, etc., to prevent slippage Action delay, effect of suppressing action delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

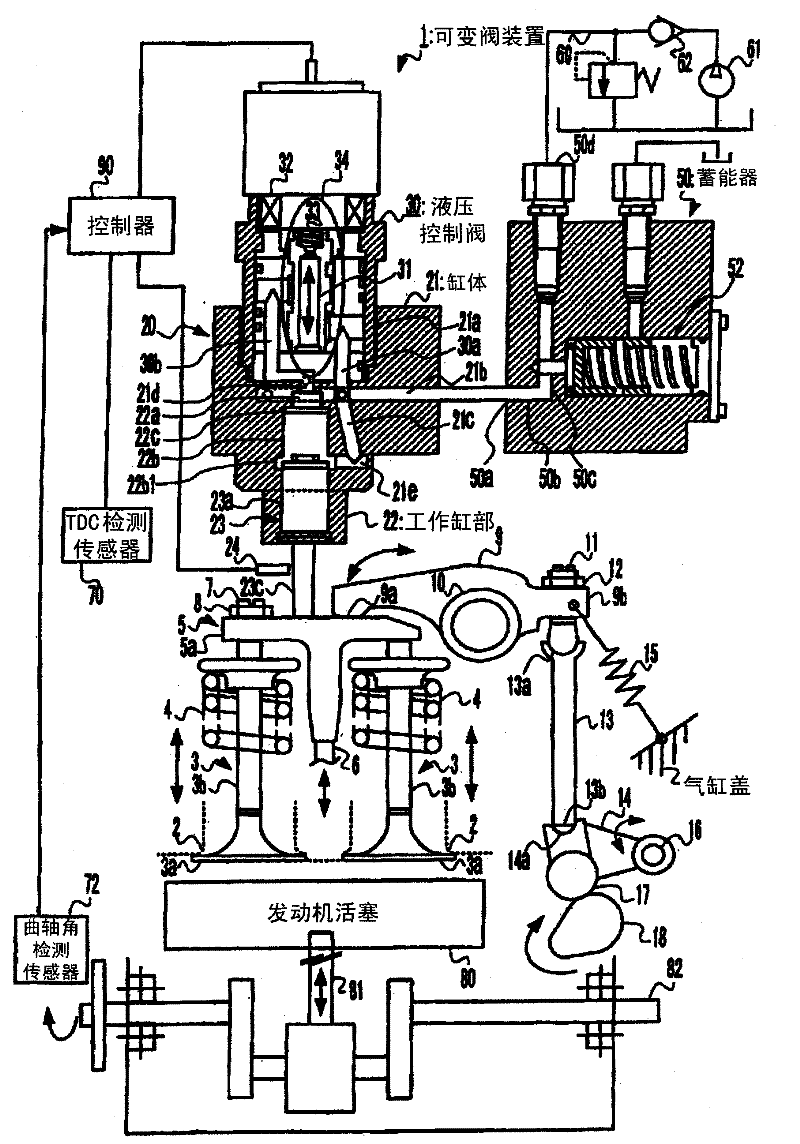

[0039] Hereinafter, an embodiment of the variable valve device and its control method according to the present invention will be described in detail with reference to the drawings.

[0040] figure 1 It is a conceptual diagram showing the variable valve device 1 according to the present invention. In this embodiment, it is assumed that the variable valve device 1 is used in a 4-cycle diesel engine. However, the variable valve device 1 according to the present invention The device is not limited to this embodiment.

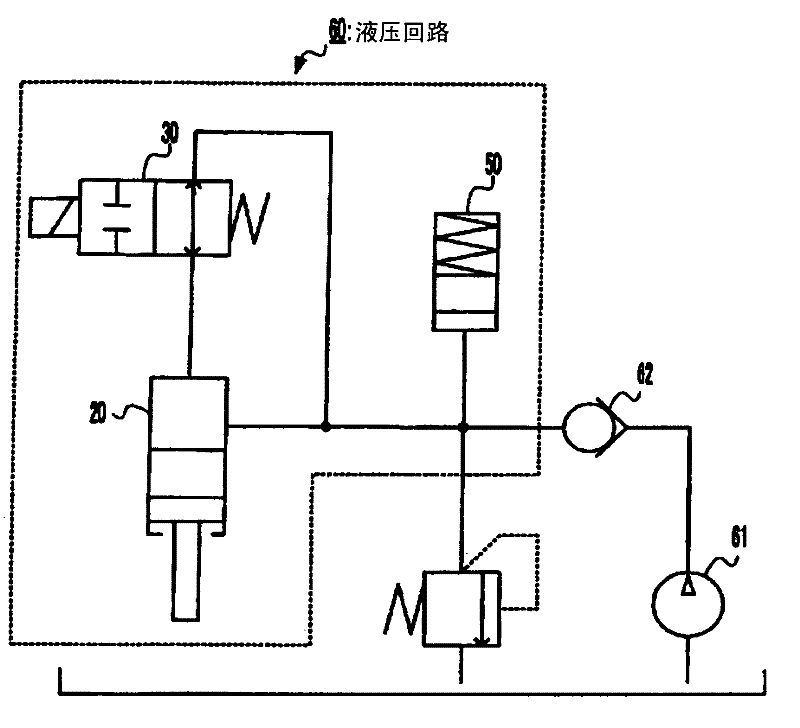

[0041] Such as figure 1 As shown, the variable valve device 1 includes a controller for controlling the variable valve device (hereinafter, simply referred to as a controller) 90, a gap sensor 24, a TDC (=Top Dead Center, top dead center) detection sensor 70, a crank angle detection sensor 72, constitute the hydraulic circuit 60 described later (refer to figure 2 ) hydraulic actuator 20, hydraulic control valve 30, accumulator 50 and diesel engine.

[0042] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com