Sliding sleeve

A sliding sleeve and coaxial technology, applied in the direction of motor vehicles, linear motion bearings, anti-centrifugal force rotating parts, etc., can solve the problems of unsuitable for retractable steering shaft bearings, high surface quality, manufacturing costs, etc., to achieve The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

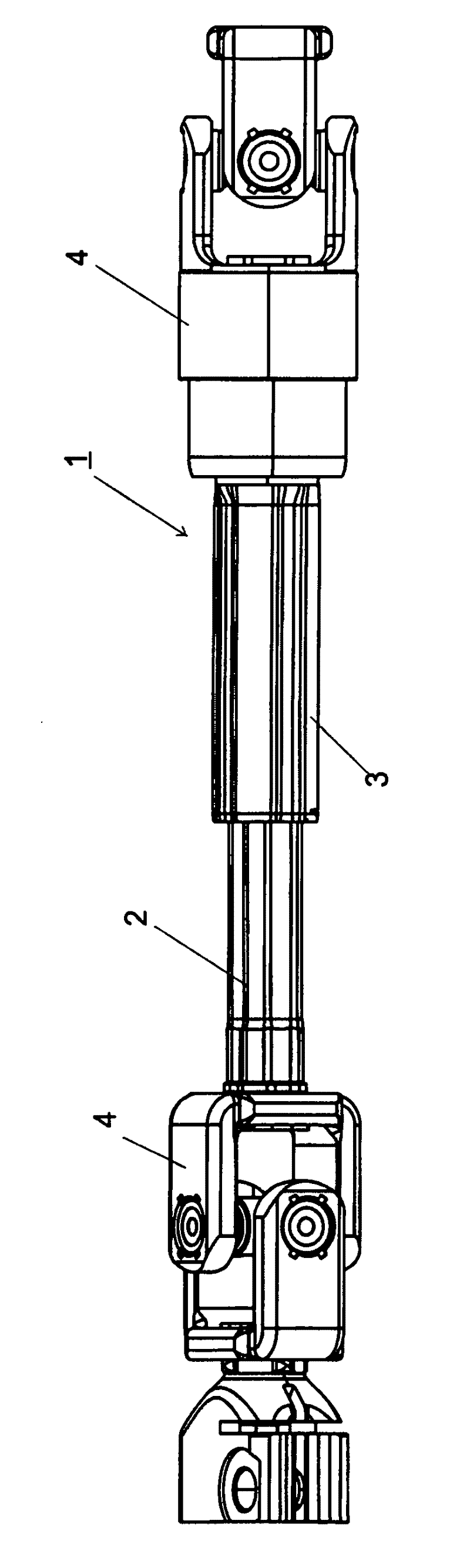

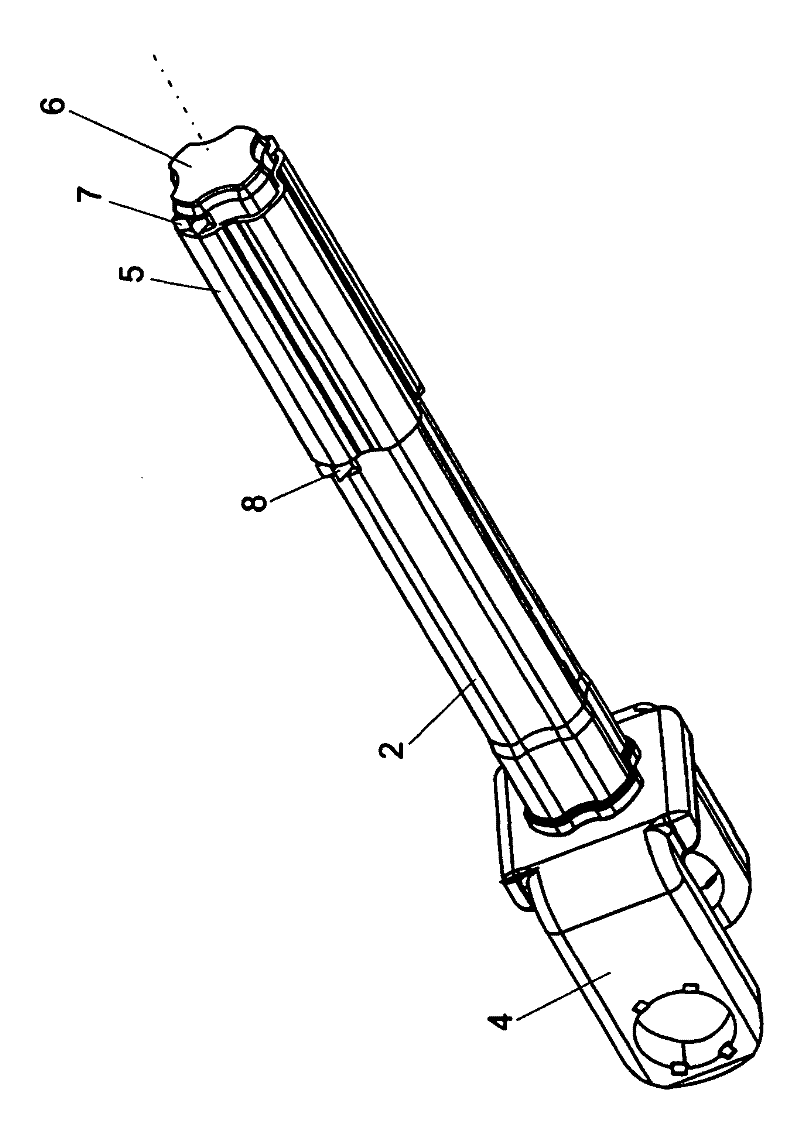

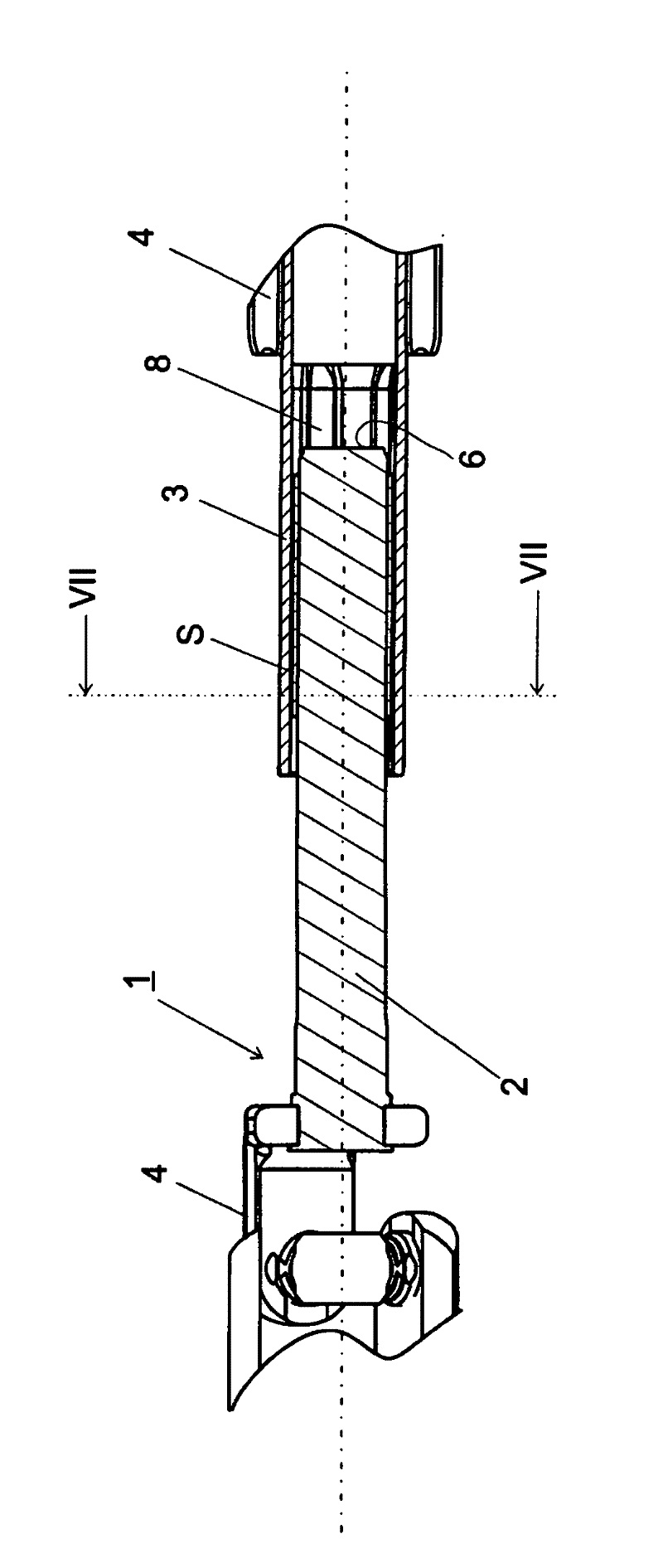

[0024] exist figure 1 A side view of the telescoping steering shaft 1 is shown in . The steering shaft 1 includes an inner shaft 2 and an outer shaft 3 . The inner shaft 2 is provided with a non-circular, in this example roughly cloverleaf-shaped cross-section. The outer shaft 3 is tubular in shape and has a hollow cross-section which is complementary to the outer peripheral contour of the inner steering shaft. The inner shaft 2 and the outer shaft 3 each carry on the end faces a connecting piece 4 known per se for a universal joint for connecting a steering gear with a steering column. In this example, a universal joint is shown as joint, in which a pin (pin cross) of the universal joint crosshead is mounted rotatably in a connection part 4 designed as a fork, wherein the fork The support structures of the shape are vertically offset from each other, but it is conceivable and possible that other joints or entirely different elements are connected to the telescoping shaft p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com