Membrane structure of high-temperature oxidation-resistant selective absorption membrane for inner pipe of condensation solar thermal power generation collector pipe

A high-temperature anti-oxidation and concentrated solar energy technology, which is applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of insufficient component structure, poor high-temperature anti-oxidation performance, and incompetence for work tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

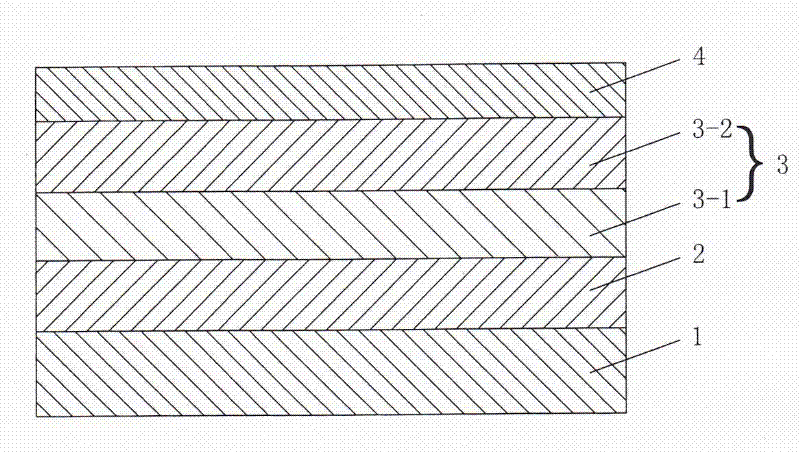

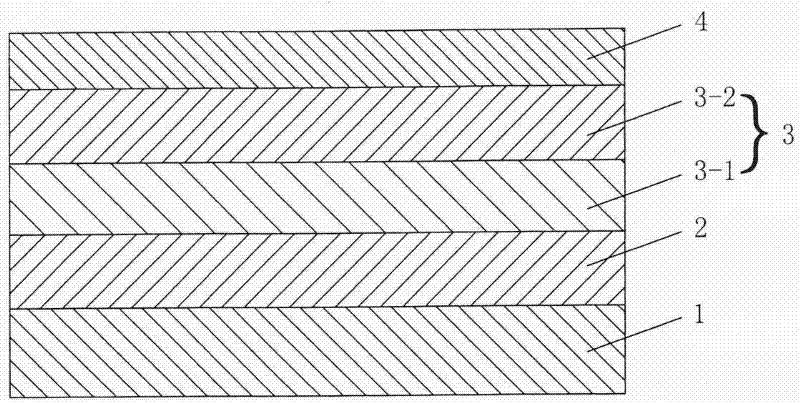

[0021] One of the specific implementation modes, as attached figure 1 shown.

[0022] A film system structure of a high-temperature anti-oxidation selective absorption film used for the inner tube of a concentrated solar thermal power generation heat collector tube, including a stainless steel substrate 1, on the surface of the stainless steel substrate 1, Ti film 2 and TiAlON film 3 in sequence from inside to outside and Al 2 o 3 film4. The TiAlON film 3 includes a first TiAlON film 3-1 with a high N content and a second TiAlON film 3-2 with a low N content, which are arranged in sequence from the inside to the outside. Both the thicknesses of the first TiAlON film 3-1 with high N content and the second TiAlON film 3-2 with low N content are in the range of 60-90 nm, and the total thickness of the two is in the range of 120-180 nm. The thickness of the Ti film 2 is in the range of 100-150nm, Al 2 o 3 The thickness of the film 4 is in the range of 50-100 nm. The mass fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com