Double-drive traction mechanism on steel bar straightening machine

The technology of a traction mechanism and a straightening machine, which is applied in the field of steel bar straightening machines, can solve the problems of slow pulling speed of steel bars with larger diameters, inability to adapt to the pulling of steel bars of different sizes, etc., and achieves the effects of simple structure, low processing cost, and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

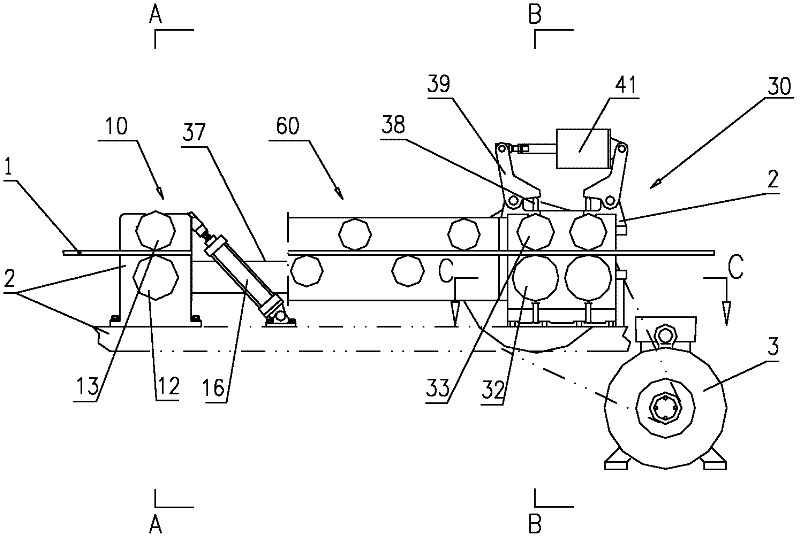

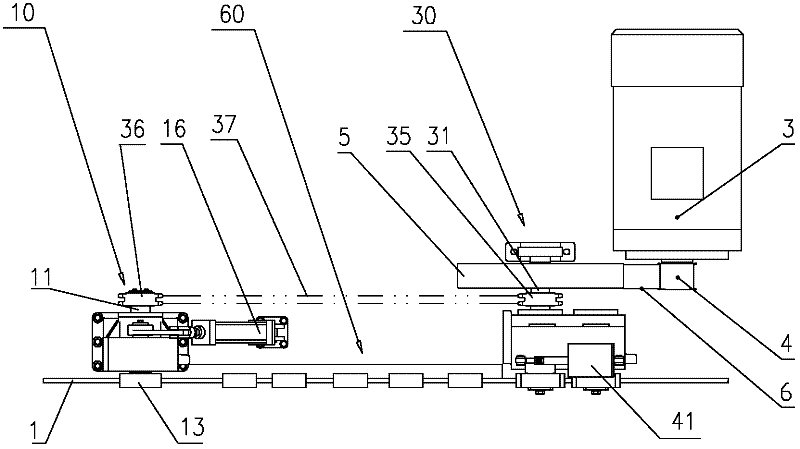

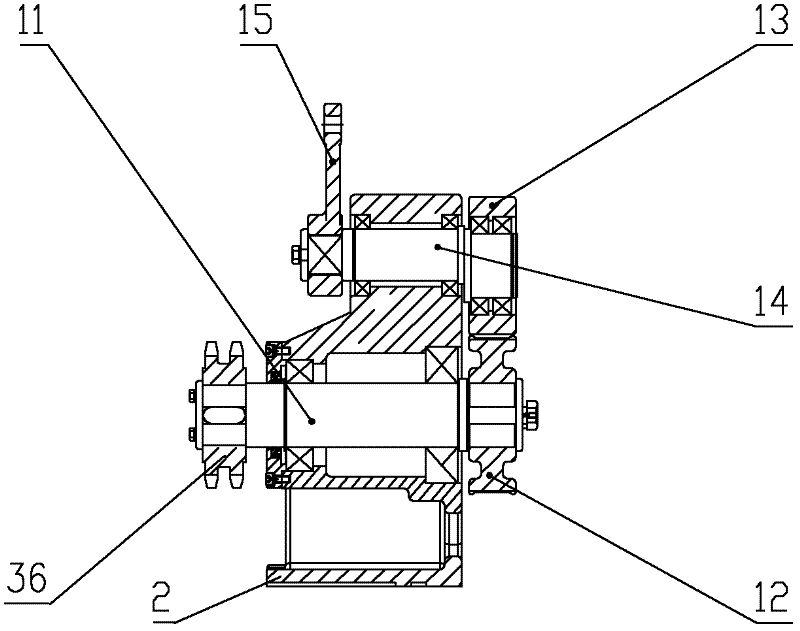

[0016] figure 1 is the front view of the present invention; figure 2 Yes figure 1 top view; image 3 Yes figure 1 Middle A-A sectional view; Figure 4 Yes figure 1 Middle B-B sectional view; Figure 5 Yes figure 1 Middle C-C section view.

[0017] The present invention provides a double-drive traction mechanism on a steel bar straightening machine. The double-drive traction mechanism includes a main drive traction mechanism 30 and a slave drive traction mechanism 10; The input end of the steel bar 1 on one side of the straightening mechanism 60, and the main driving traction mechanism 30 is located on the other side of the straightening mechanism 60 close to the output end of the steel bar 1.

[0018] One end of the main drive traction shaft 31 of the main drive traction mechanism 30 is connected to the rotary power unit; a synchronous transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com