Multi-axis driving device for double-faced grinding machine

A multi-axis drive and double-sided grinding technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems that the grinding disc and ring gear under the sun gear cannot be adjusted independently, and the adjustment can improve the distribution of the workpiece movement track. Achieve the effect of good grinding and polishing precision, high grinding efficiency, stable and reliable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] specific implementation plan

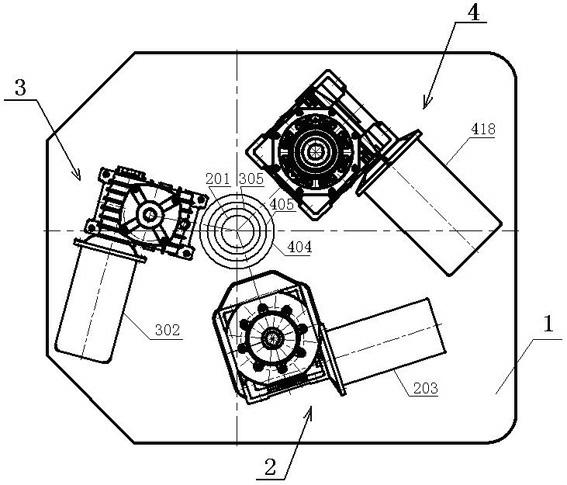

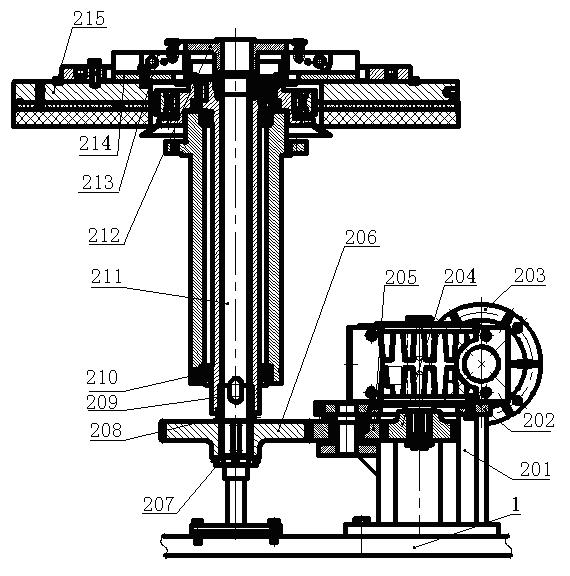

[0011] Such as figure 1 As shown, the double-sided grinding machine multi-axis driving device of the present invention includes a sun gear transmission system 3, an upper disk transmission system 2 and a lower disk transmission system 4 which are arranged on the base plate 1 roughly according to an equal circle; the upper disk transmission system 2 The central shaft 201 is fixed on the bottom plate 1, the sun gear hollow shaft 305 in the sun gear transmission system 3 is sleeved on the central shaft 201, the lower grinding disc hollow shaft 405 is sleeved on the sun gear hollow shaft 305, and the ring gear hollow shaft 404 Set on the hollow shaft 405 of the lower grinding disc.

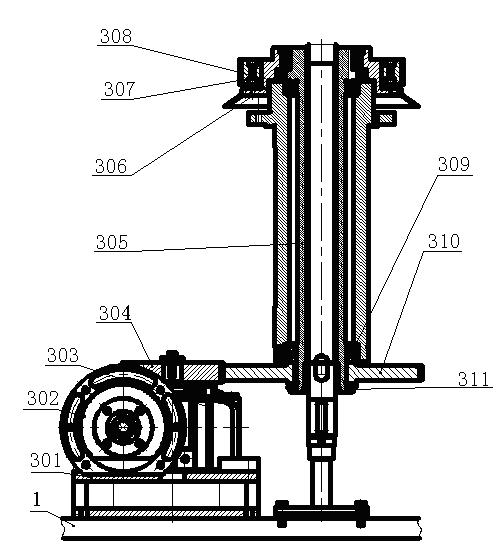

[0012] See figure 2 , the sun gear transmission system 3 includes a sun gear reducer base 301 installed on the base plate 1, the sun gear reducer 303 is fixed on the sun gear reducer base 301, and the sun gear drive motor 302 is connected with the sun gear redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com